Method and apparatus for blowing glass container by cooled gas

A glass container and manufacturing method technology, applied in glass production, head blowing and other directions, can solve problems such as high price, low production efficiency, bursting, etc., and achieve the effects of reducing production cost, improving molding efficiency, and preventing skewed bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0044] The first embodiment is the manufacturing method of using forming molds to produce glass containers, that is, the forming air is to use the cooled compressed air cooled by the cooling device, and to produce glass containers through the continuous or intermittent work of the cooled compressed air Manufacturing method.

[0045] In the following, each main content of the manufacturing method related to the first embodiment will be described separately.

[0046] 1. Glass container

[0047] (1).Shape

[0048] The shape of the glass container is not limited, and it can be a small-mouth glass bottle, a square glass bottle, a cylindrical glass bottle, an irregular-shaped glass bottle, etc. according to the needs of the application.

[0049] (2).Material

[0050] The material of the glass container is not limited, and may be soda lime glass, borosilicate glass, leaded glass, phosphate glass, aluminosilicate glass, and the like.

[0051]The color of the glass container can be...

no. 2 Embodiment

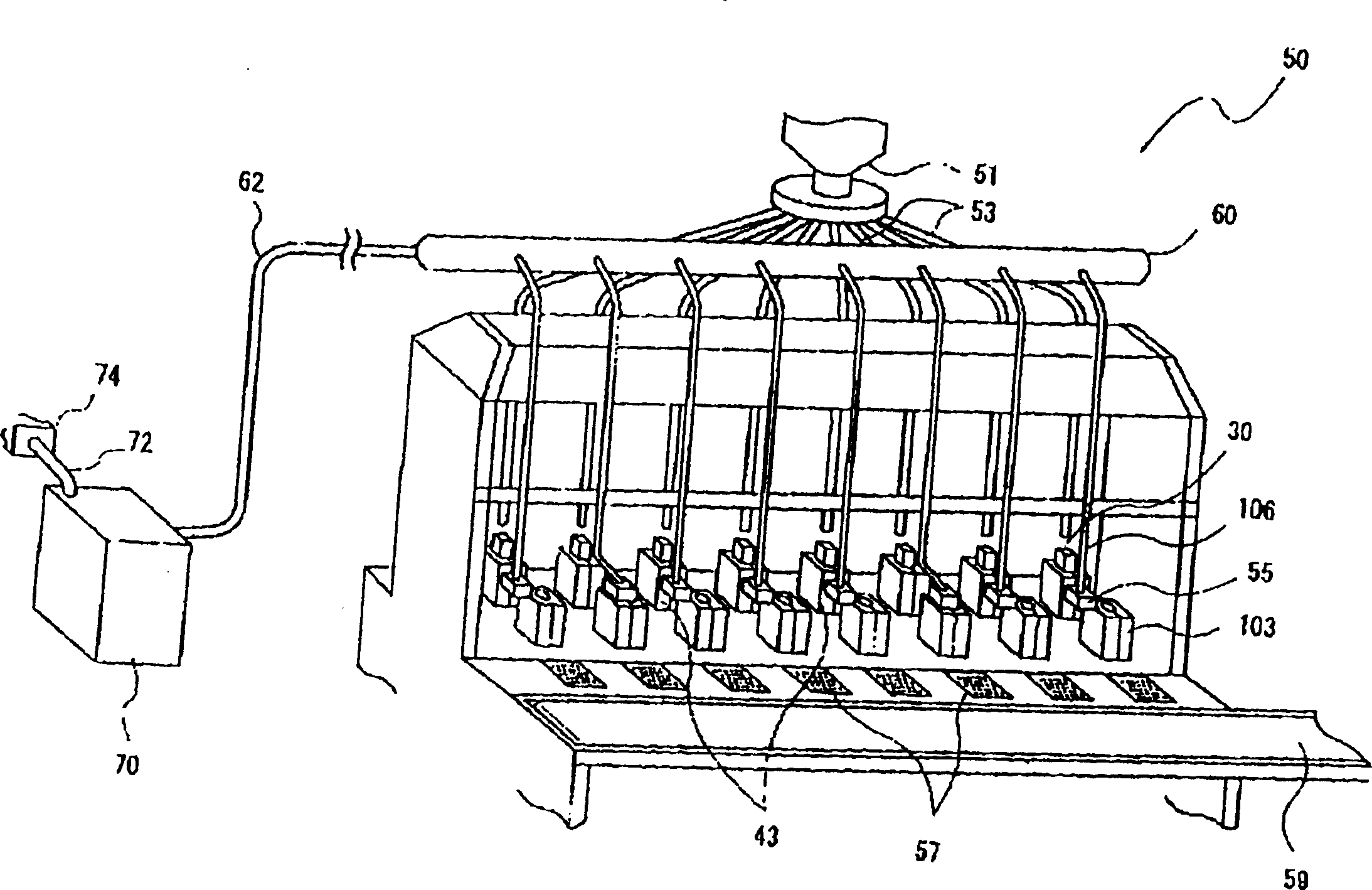

[0096] The second embodiment is as figure 1 As shown, a glass container manufacturing apparatus 50 equipped with a molding die 103 is provided. The manufacturing device 50 is characterized in that it is equipped with a cooling device 70 for cooling compressed air.

[0097] Each main part of the manufacturing apparatus 50 will be described in detail below.

[0098] 1. Forming mold

[0099] In the second embodiment, the molding die shown in Figure 10(a)~(c) should be used.

[0100] (1). Initial mold

[0101] The initial mold is different according to the different shapes of the glass container. In actual use, the inner cavity of the primary mold should also be demoulded.

[0102] In order to prevent the primary mold from sticking to the glass container blank, the primary mold should also be cooled from the outside of the primary mold or from the inside of the primary mold.

[0103] (2). Molding

[0104] Molding is also different according to the different shapes of the gl...

example

[0152] Below by example, the content of the present invention is described in more detail. Of course, the technical scope of the present invention is not limited to the examples. Appropriate changes can be made within the scope of the purpose of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com