Motor vibration-resisting device for vacuum dust collector

A vacuum cleaner and anti-vibration device technology, applied in vacuum cleaners, applications, household appliances, etc., can solve problems such as inability to eliminate vibration, achieve the effect of improving reliability, preventing vibration and vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

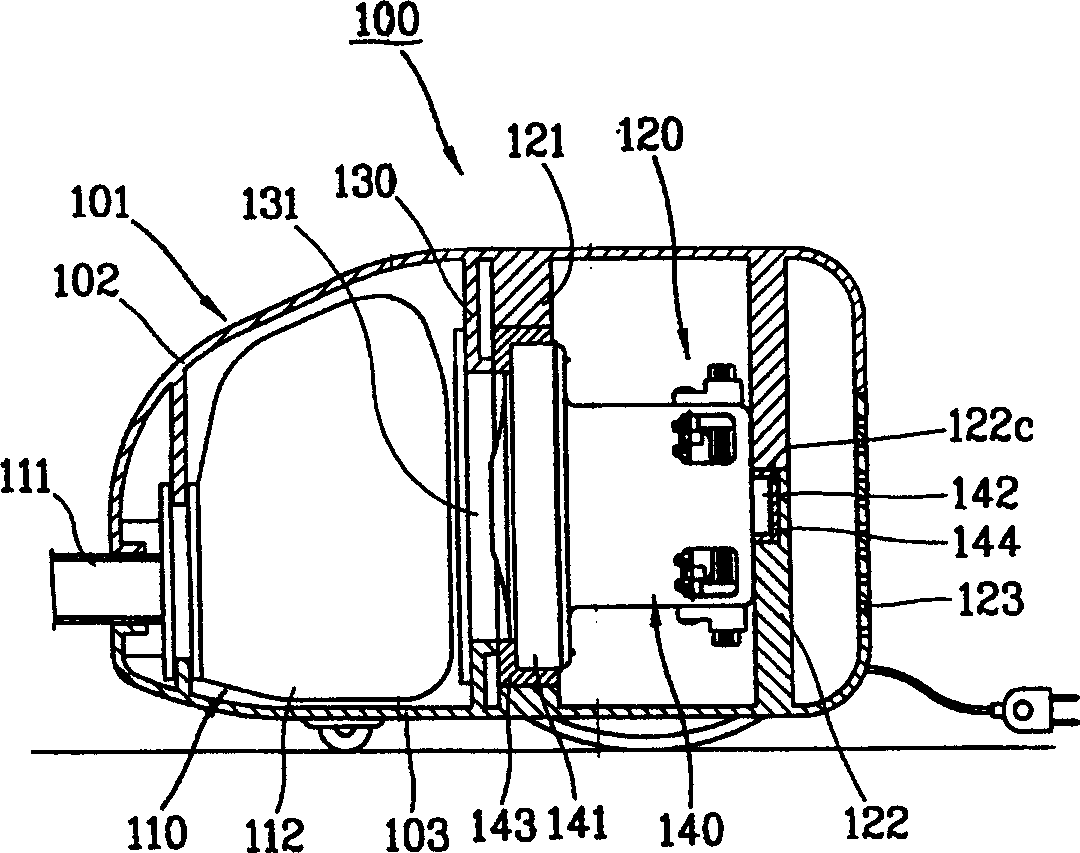

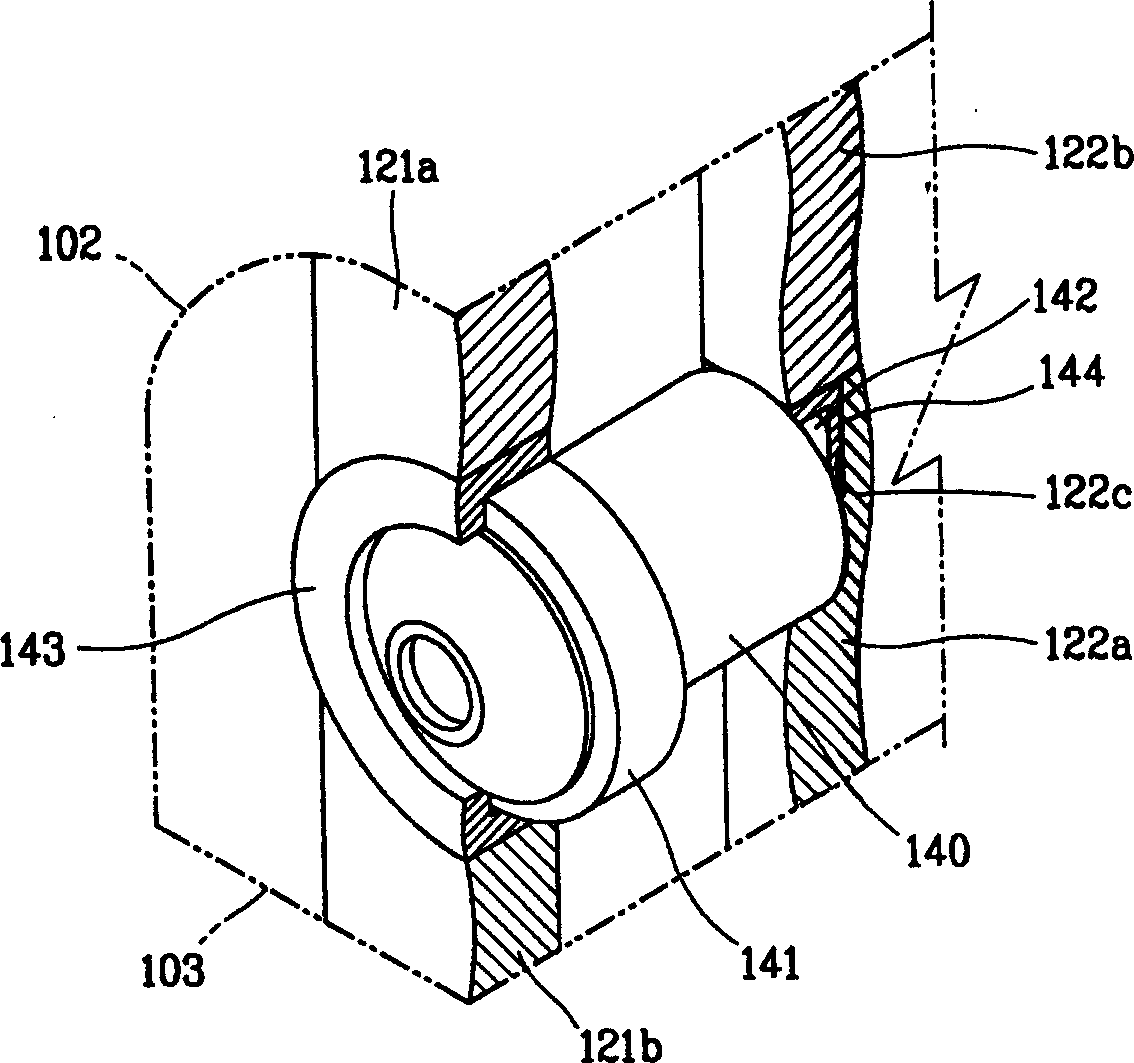

[0026] Embodiments of the present invention are further described in detail below in conjunction with the accompanying drawings:

[0027] The present invention is a motor anti-vibration device for a vacuum cleaner. Its structure includes a motor 50 with an impeller cover casing 51. There is a bearing mounting frame 52 behind the casing of the motor 50. The anti-vibration device also includes a The shell 11 and the lower shell 12 are separated from the independent motor bracket 60, and the support frame 62 and the sealing support frame 63 at both ends of the motor bracket 60 fix the motor 50; wherein the support frame 62 is installed on the outside of the impeller cover shell 51, and the bearing mounting frame 52 is inserted and fixed on the In the fixing groove 64 of the sealing support frame 63 .

[0028] The motor bracket 60 includes a support plate 61 connecting two ends of the support frame 62 and a sealing support frame 63 , and a shockproof component 70 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com