Digital display horizontal and dip measurer

A digital display and measuring instrument technology, applied in measuring devices, measuring inclination, instruments, etc., can solve the problems of angle measurement distortion, high cost, poor stability, etc., and achieve easy processing and assembly, little influence of external conditions, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further illustrate the technical solution of the present invention, the following are several non-limiting embodiments of the present invention.

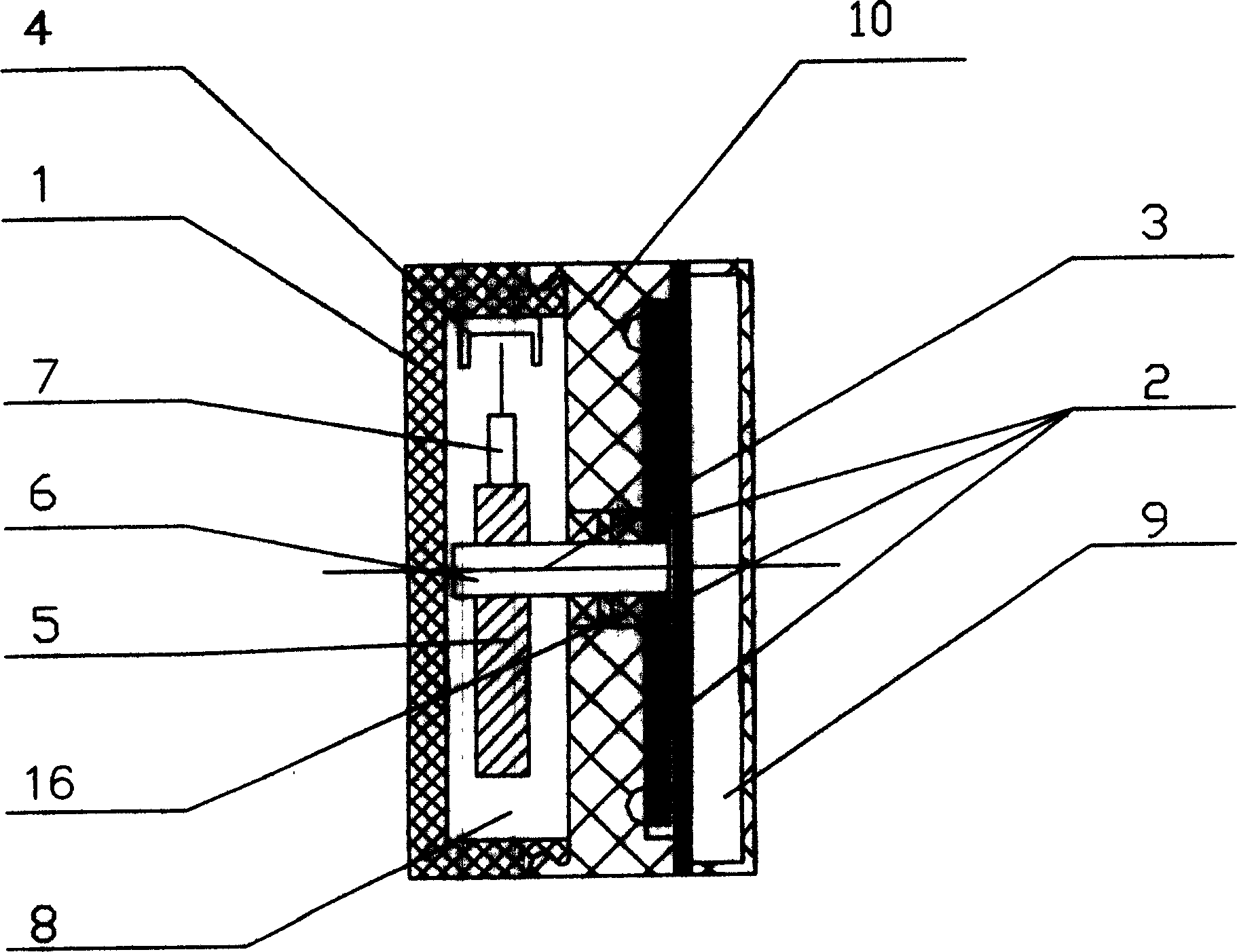

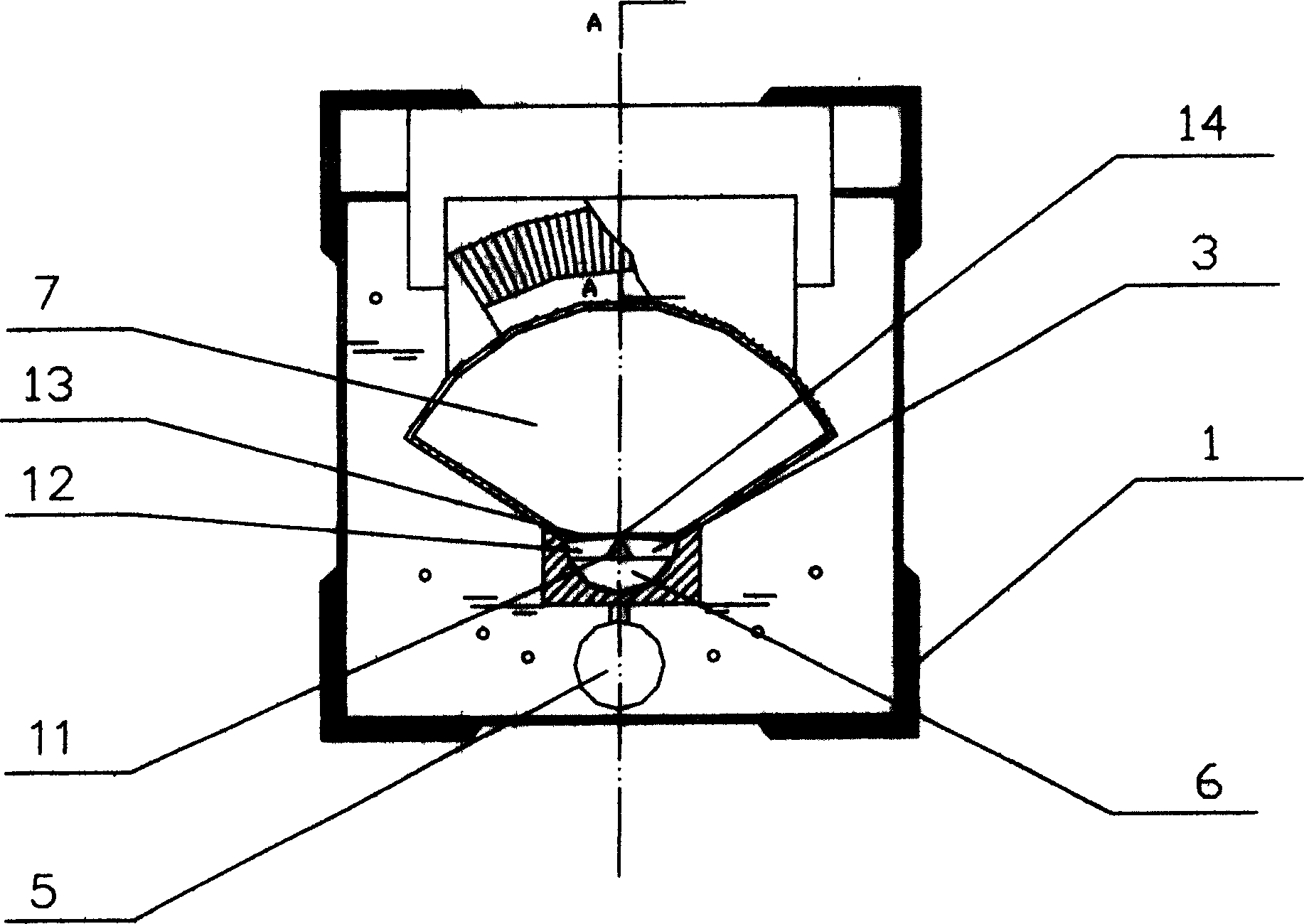

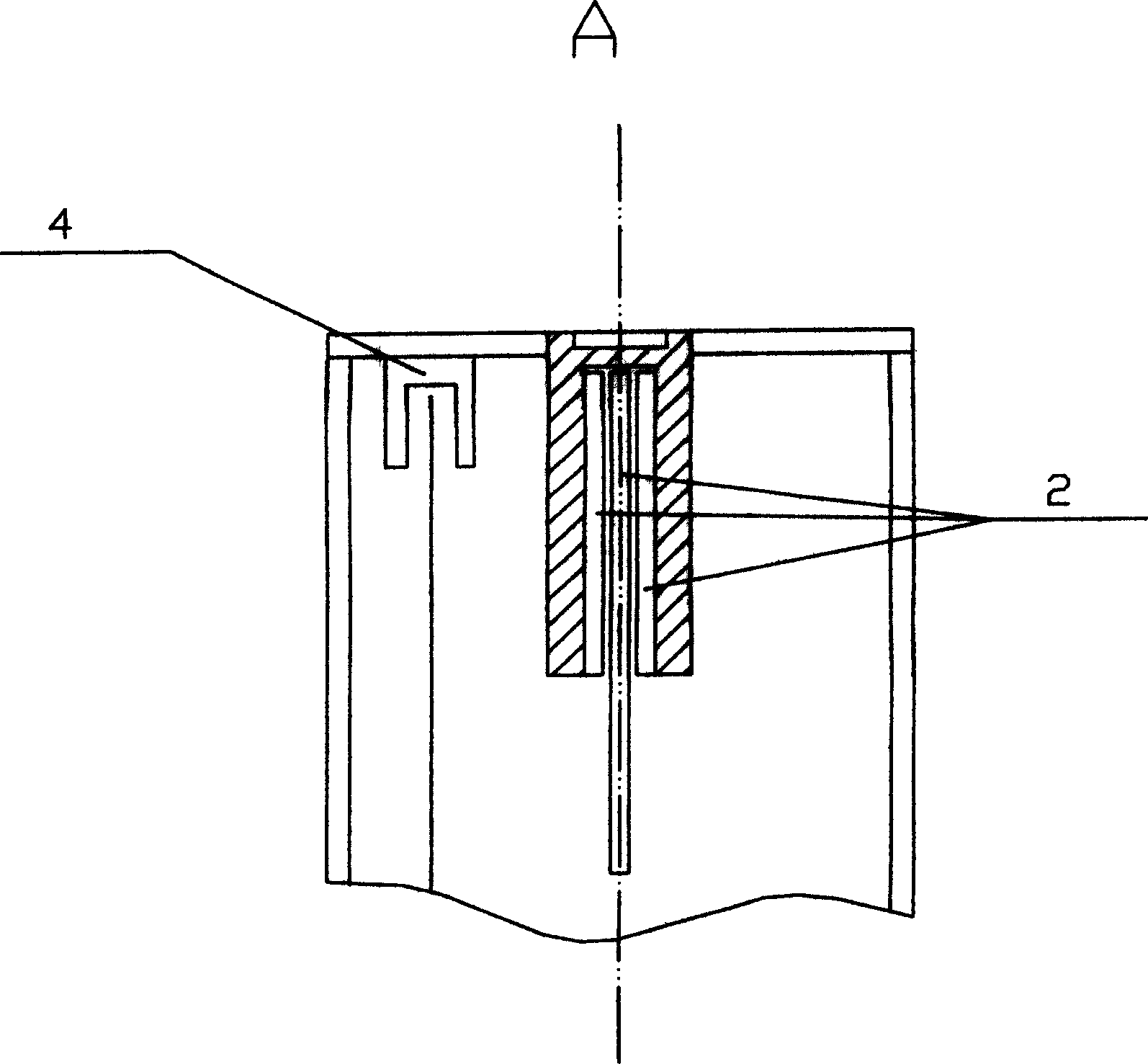

[0013] figure 1 Shown is a typical structure of the swing shaft implementation in the present invention, which is the simplest implementation. This implementation is composed of a housing 1, a capacitive angle measuring sensor and a gravity vertical device 3. The capacitive angle measuring sensor The main grid or auxiliary grid 2 is fixed on the casing 1; in order to determine the absolute zero position of the measuring instrument, a position switch 4 is also provided on the casing 1, which is a precision position switch. Gravity vertical device 3 is made up of weight 5 and supporting shaft 6, and in this embodiment, supporting shaft 6 is a rotating shaft in fact, and is hinged on the axle seat 16 that is connected with shell 1, and axle seat 16 and shell 1 There are also various ways of fixing, but in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com