DC brushless motor with decelerator

A brushless DC motor and reducer technology, applied in the direction of DC commutator, electrical components, electromechanical devices, etc., can solve the problems of high speed, difficult maintenance of mechanical brake mechanism, difficult driver design, etc., and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

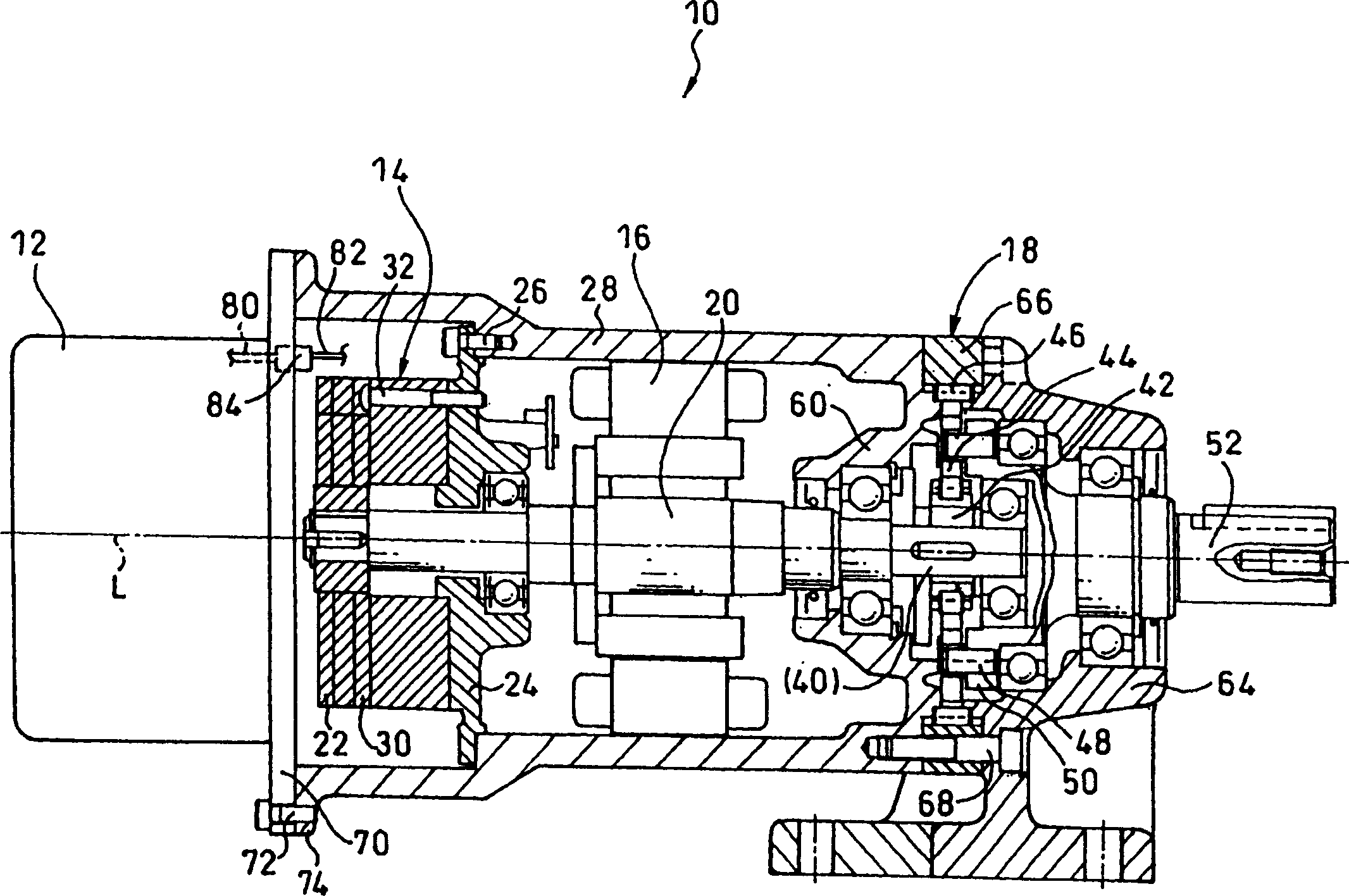

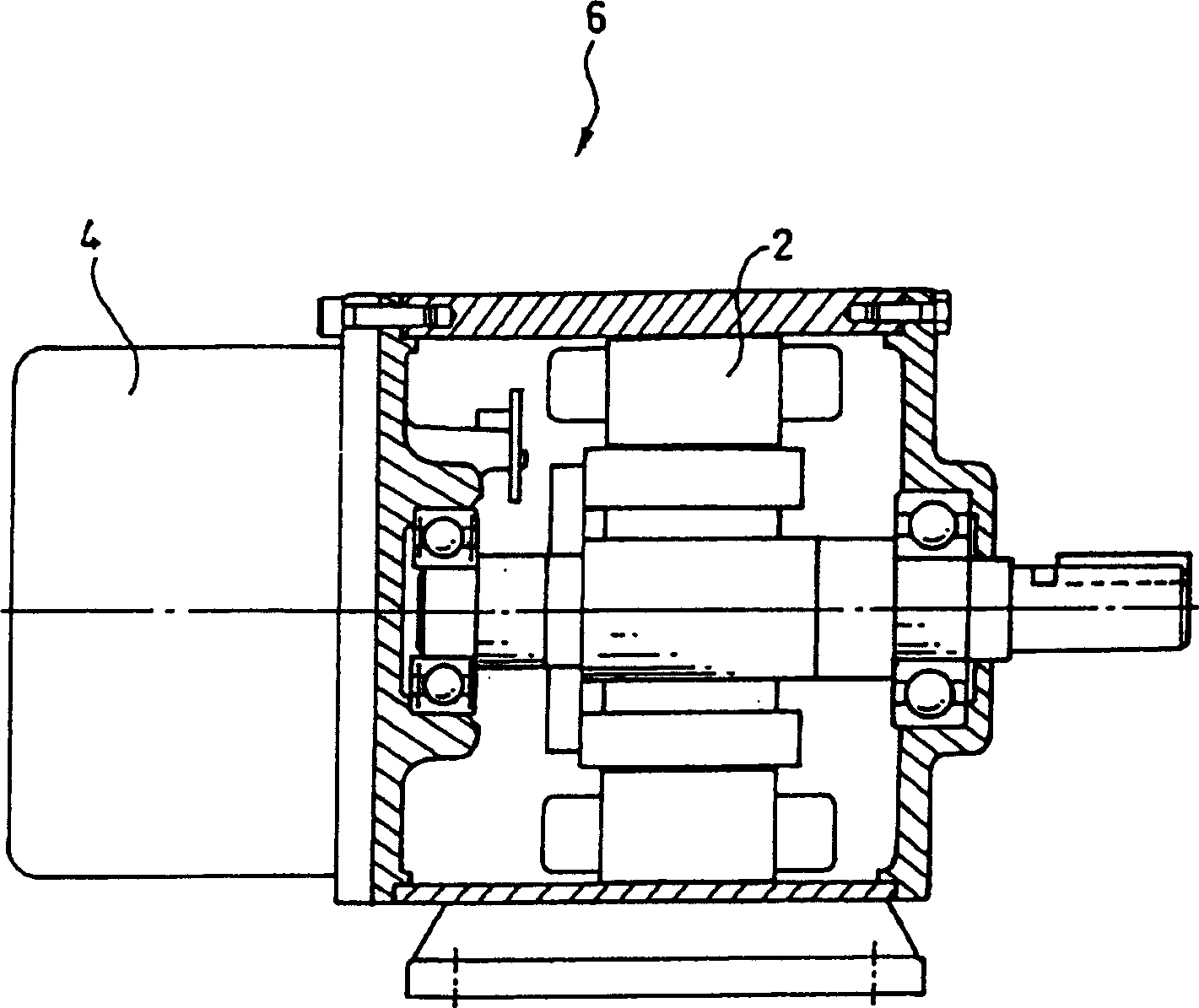

[0019] figure 1 An example of a brushless DC motor with a reducer to which the embodiment of the present invention is applied is shown.

[0020] The DC brushless motor 10 with a reducer includes a driver 12, a mechanical brake mechanism 14 and a motor main body 16 which are sequentially installed on the same axis L. In addition, the reducer 18 is also continuously installed on the same axis L.

[0021] The driver 12 converts single-phase or three-phase alternating current (AC) into direct current (DC), and at the same time generates electrical energy for controlling and driving the motor body 16. The driver 12 has a built-in regenerative braking circuit (the figure is omitted), which is designed to recover the braking energy generated during braking. In addition, the braking of the motor main body 16 that relies on the function of the driver 12 is to reduce the rotation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com