Water-absorbency resin composition

A resin composition and water-absorbing technology, applied in absorbent pads, medical science, bandages, etc., can solve problems such as deterioration, low liquid permeability or gel strength, urine leakage from disposable diapers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

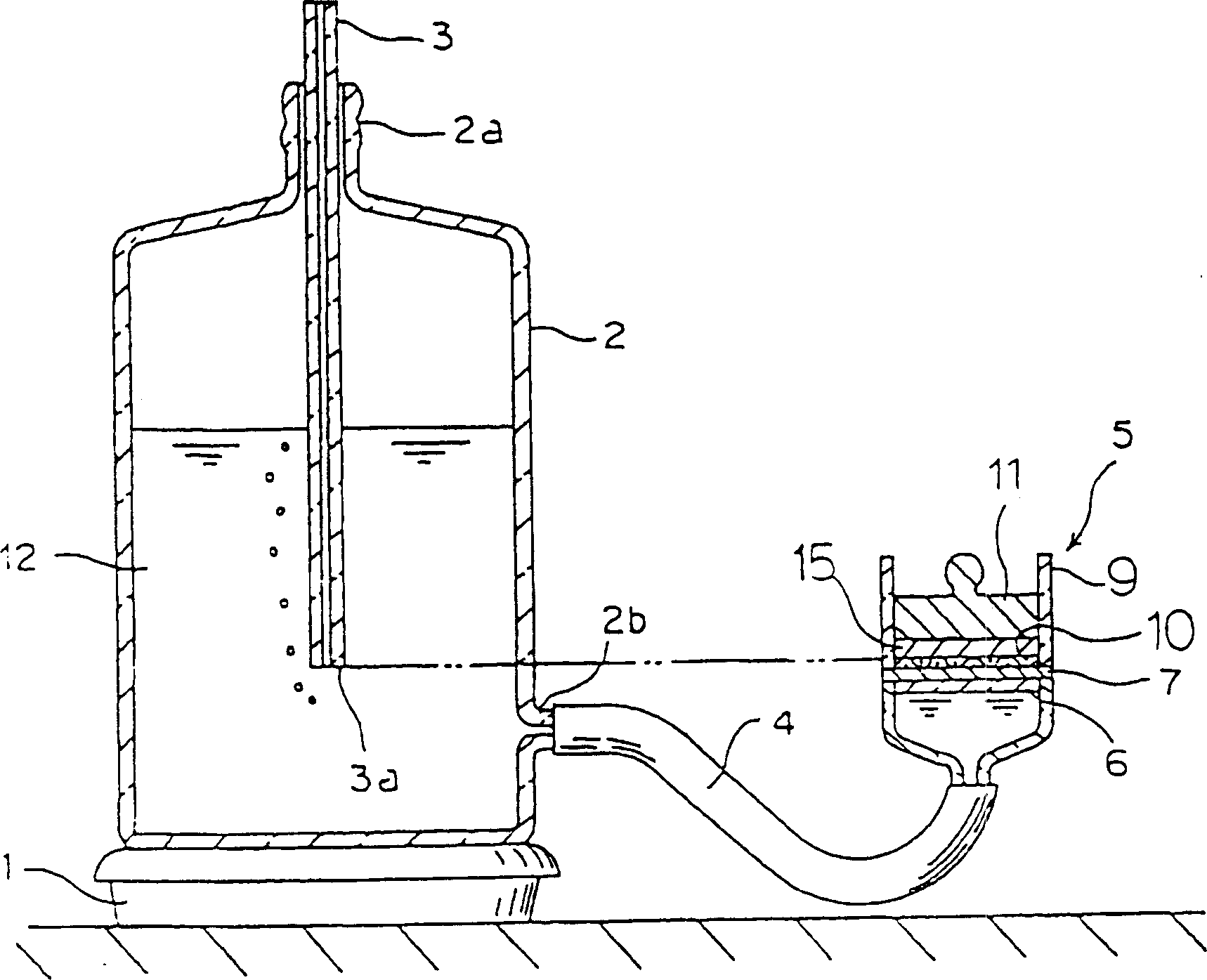

Image

Examples

Embodiment 1

[0118] Under stirring conditions, 60% sulfuric acid was added into a commercially available pentasodium diethylenetriaminepentaacetic acid aqueous solution (40% solid content) to adjust the pH to a range of 1.8 to 2. The resulting solution was left to stand for a while, and then deposited diethylenetriaminepentaacetic acid was filtered off, washed with pure water and dried at 60°C.

[0119] The total content of nitrilotriacetic acid (salt) in the commercially available diethylenetriaminepentaacetic acid pentasodium is about 5%, but through the above-mentioned treatment, the nitrilo group in the obtained diethylenetriaminepentaacetic acid The total content of triacetic acid (salt) was reduced to 35ppm of diethylenetriaminepentaacetic acid.

[0120] Add 0.05 parts of ethylene glycol diglycidyl ether, 1 part of propylene glycol, 3 parts of water and 1 part of isopropyl to 0.002 parts of diethylenetriaminepentaacetic acid obtained above with a reduced total content of nitrilotriac...

Embodiment 2

[0123] The water-absorbent resin composition (2) was obtained in the same manner as in Example 1, except that the amount of diethylenetriaminepentaacetic acid in the treatment agent solution was changed to 0.01 part (diethylenetriaminepentaacetic acid in the obtained composition The mixing ratio of the water-absorbent resin (A) is 100ppm).

[0124] The total content of nitrilotriacetic acid (salt) in the water absorbent resin composition (2) was measured. As a result, the content was equal to or less than 0.1 ppm of the composition, so it could not be measured. Table 1 shows the measurement results of physical properties of the water-absorbent resin composition (2).

Embodiment 3

[0126] Diethylenetriaminepentaacetic acid (obtained in Example 1) having a reduced total nitrilotriacetic acid (salt) content was dissolved in water to prepare a 0.07% aqueous solution. 3 parts of this solution was sprayed on 100 parts of the water-absorbent resin (B) (obtained in Reference Example 1), and then dried at 80°C to obtain a water-absorbent resin composition (3) (in which diethylenetriaminepentaacetic acid The mixing ratio is 21 ppm of the water absorbent resin (B).

[0127] The total content of nitrilotriacetic acid (salt) in the water absorbent resin composition (3) was measured. As a result, the content was equal to or less than 0.1 ppm of the composition, so it could not be measured. Table 1 shows the measurement results of physical properties of the water-absorbent resin composition (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com