Electric wire removing roller for LP insulator and power distribution method of construction

A technology of insulators and rollers, used in electrical components, cable installation, cable laying equipment, etc., can solve the problems of difficult wire movement, manual installation, and difficulty in ensuring working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

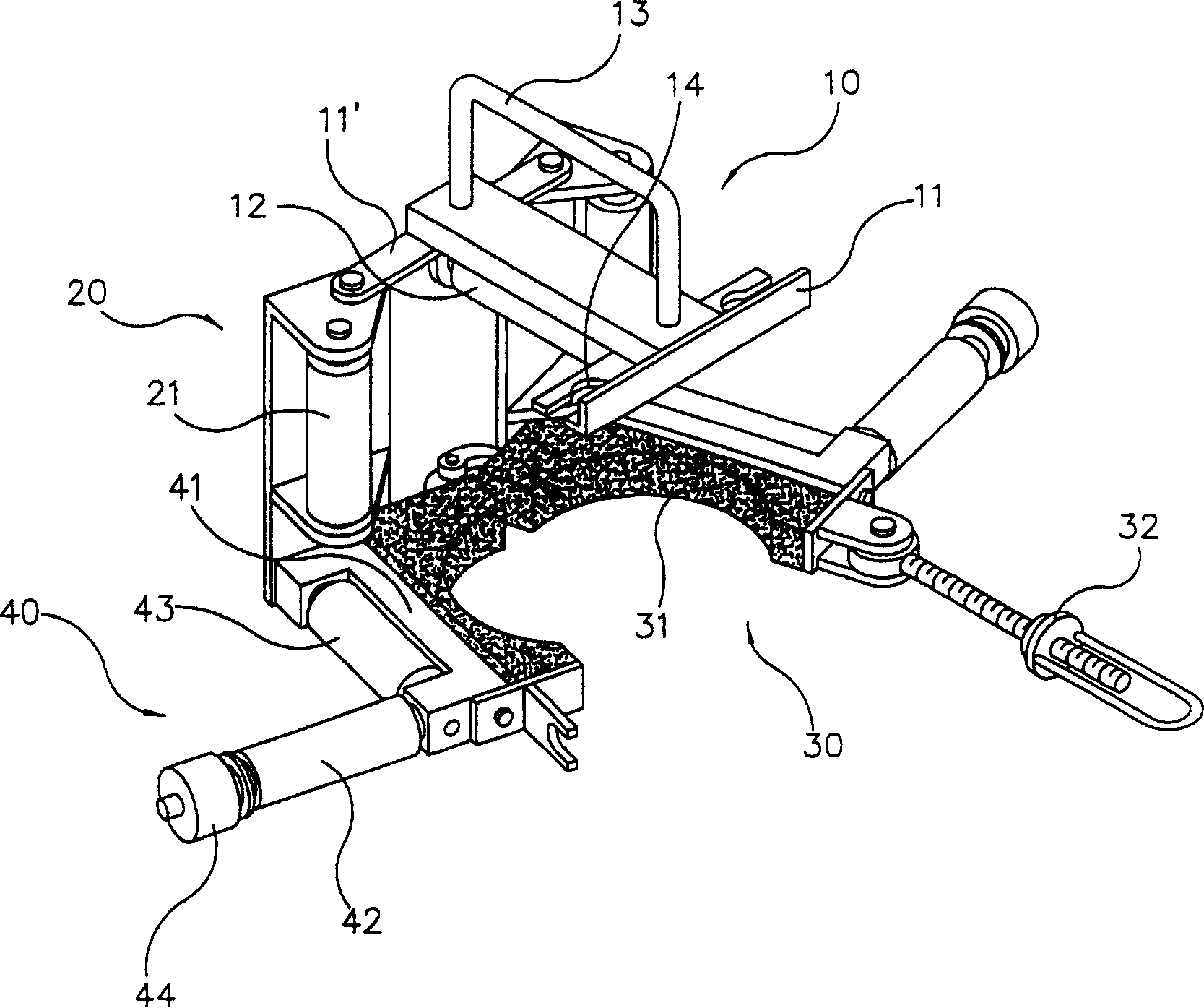

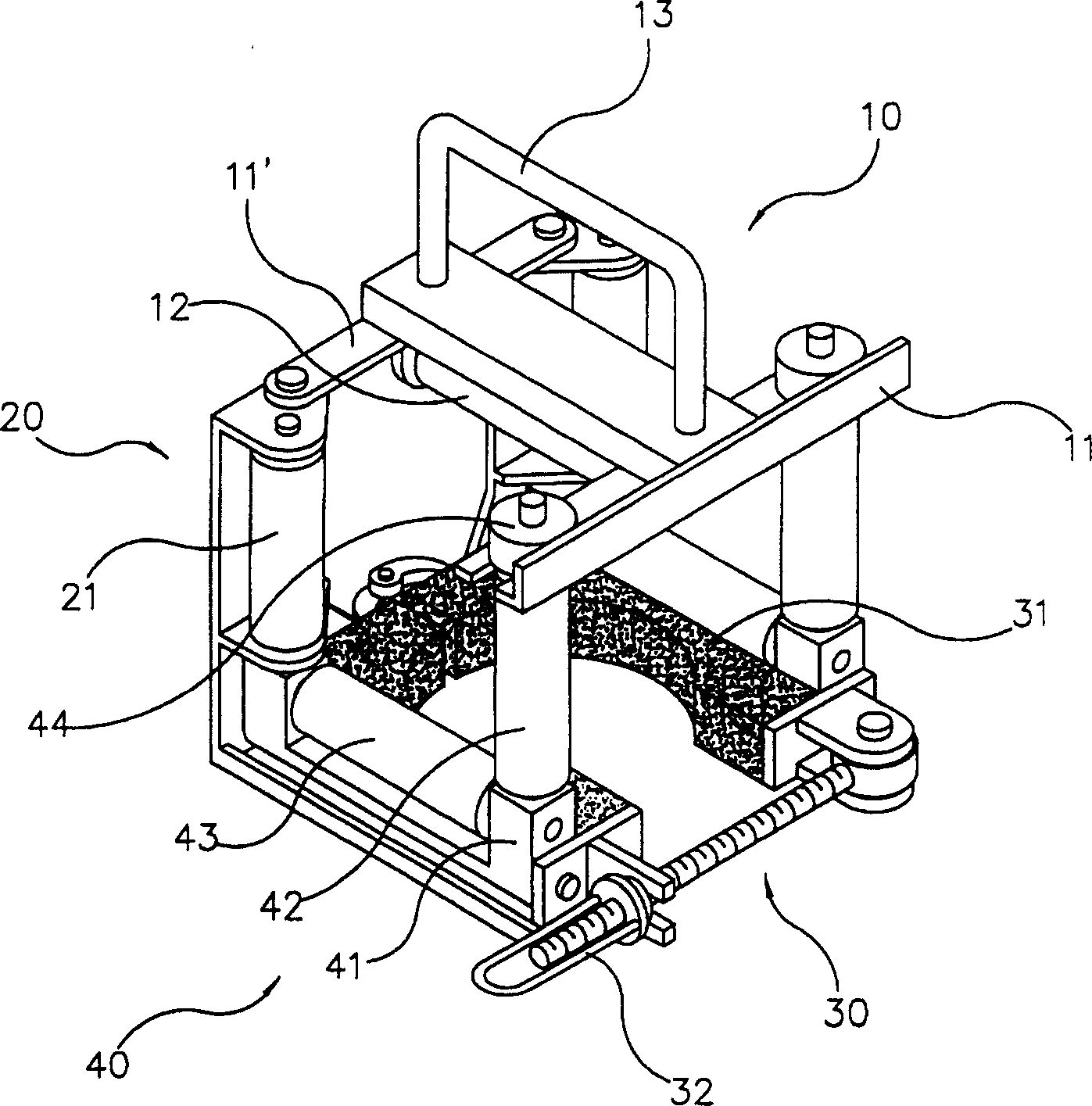

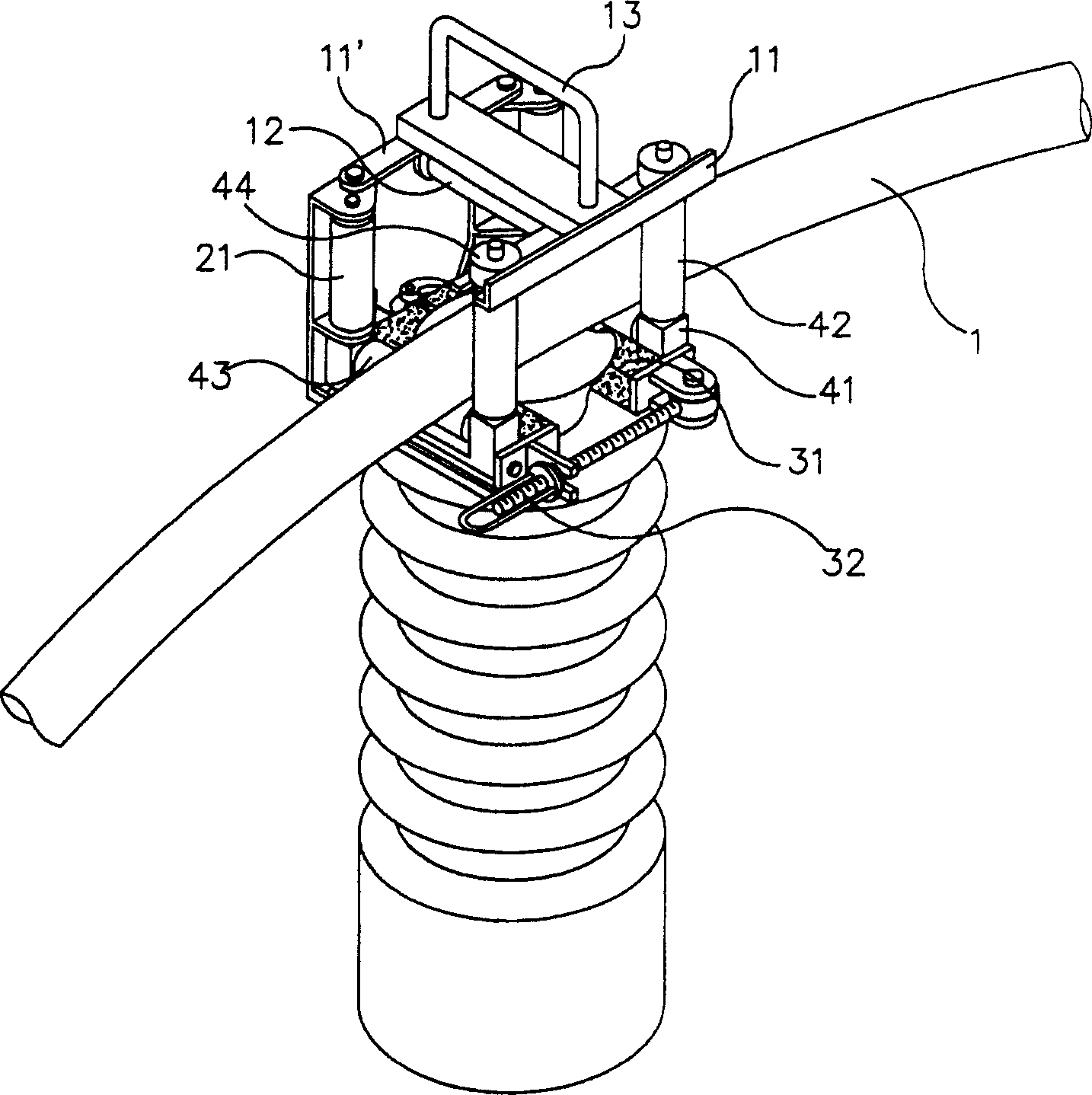

[0025] figure 1 is an overall perspective view of the stranding roller of the present invention in an open state; figure 2 is a perspective view of the stranding roller of the present invention in a closed state.

[0026] The stranding roller comprises: an upper support device 10, with front and rear support brackets 11, 11', an upper roller 12 rotatably mounted on the lower part of the upper support device by these two brackets, and a handle 13 fixed on the upper part of the upper support device ; vertical support device 20, which is axially mounted on the rear support bracket 11' rotatably at right angles, and has vertical rollers 21 installed in the same direction; insulator engaging device 30, which has a pad 31 with a half The circular inner peripheral surface is coaxially rotatable with the vertical supporting device 20, and is connected to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com