Fuel shooting valve

A fuel injection valve and fuel technology, which is applied to fuel injection devices, charging systems, engine components, etc., can solve problems such as discreteness, and achieve the effect of ensuring reliability, stable cooling effect, and reducing solids difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

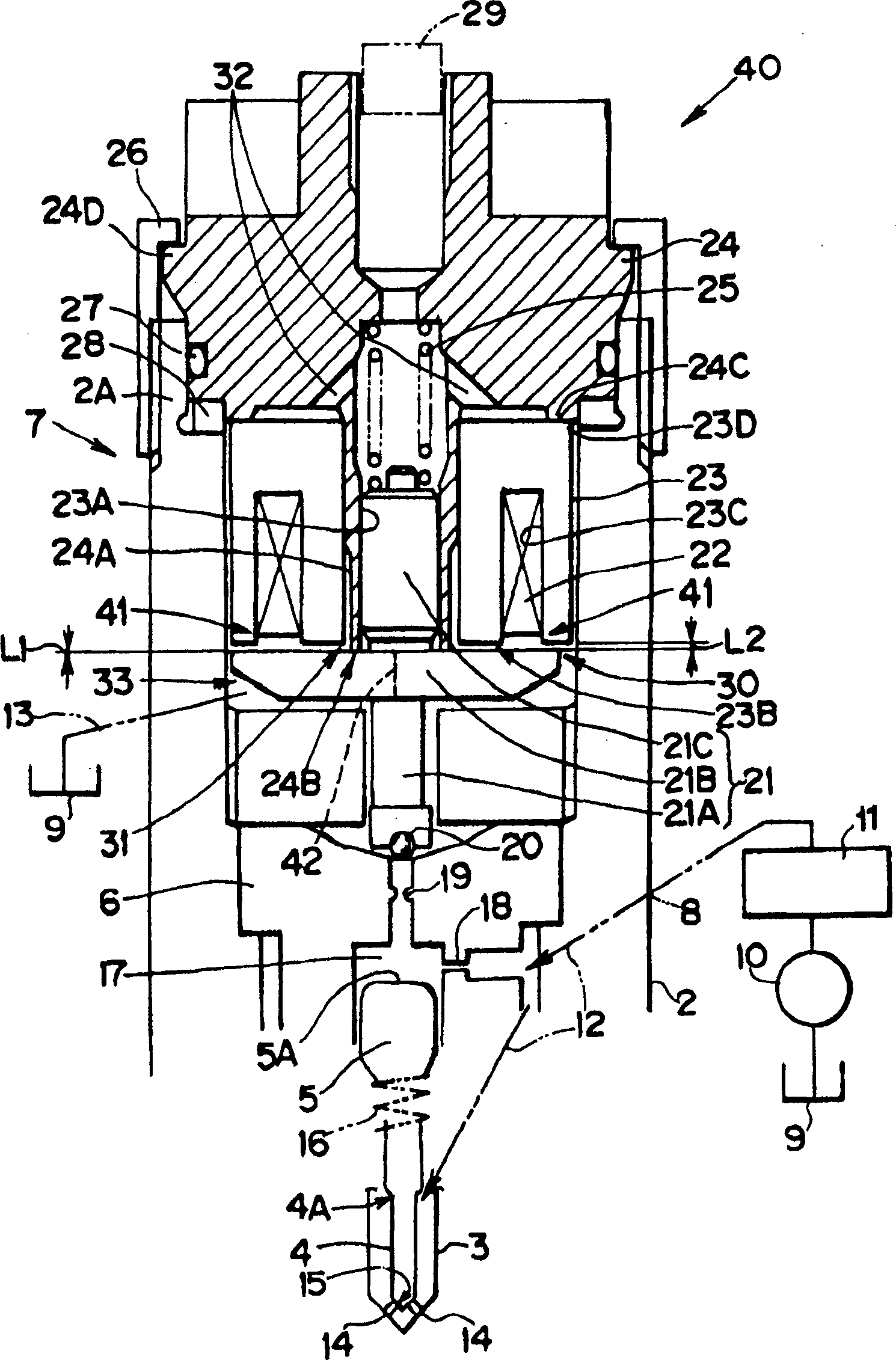

[0063] Below, according to figure 1 Embodiments of the present invention will be described in detail through FIG. 4 . and Figure 8 ~ Figure 11 The same symbols are assigned to the same parts, and detailed description thereof will be omitted here.

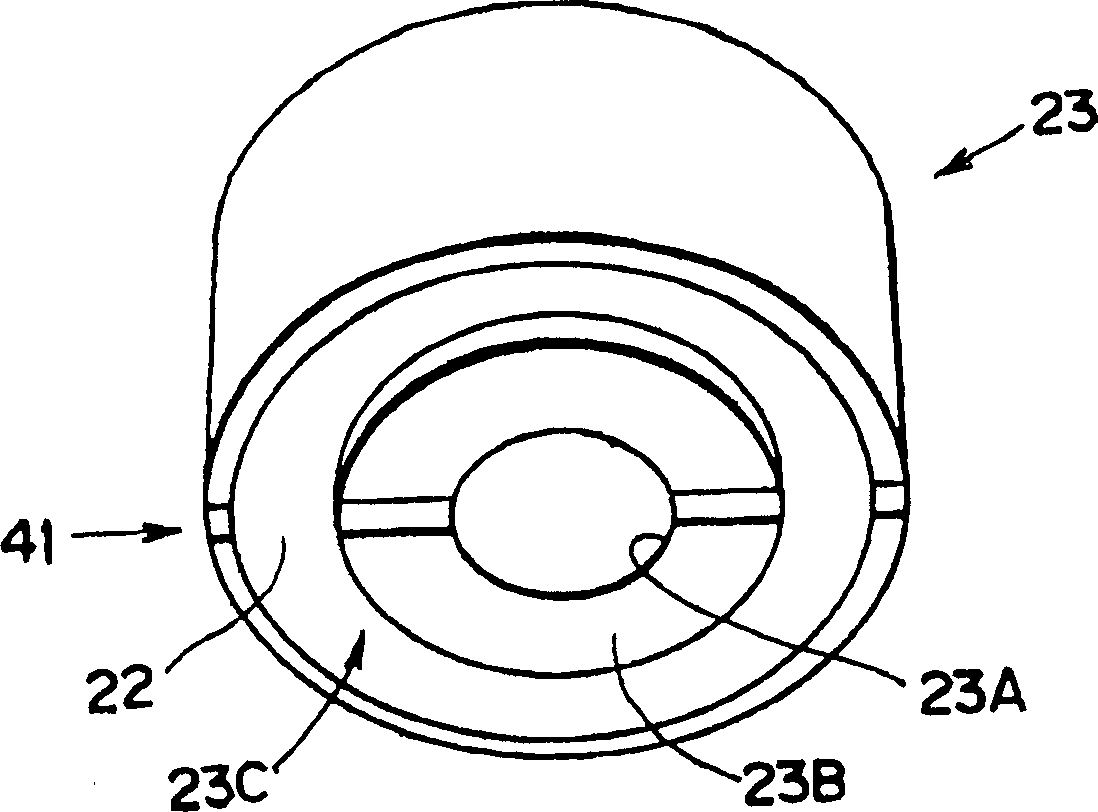

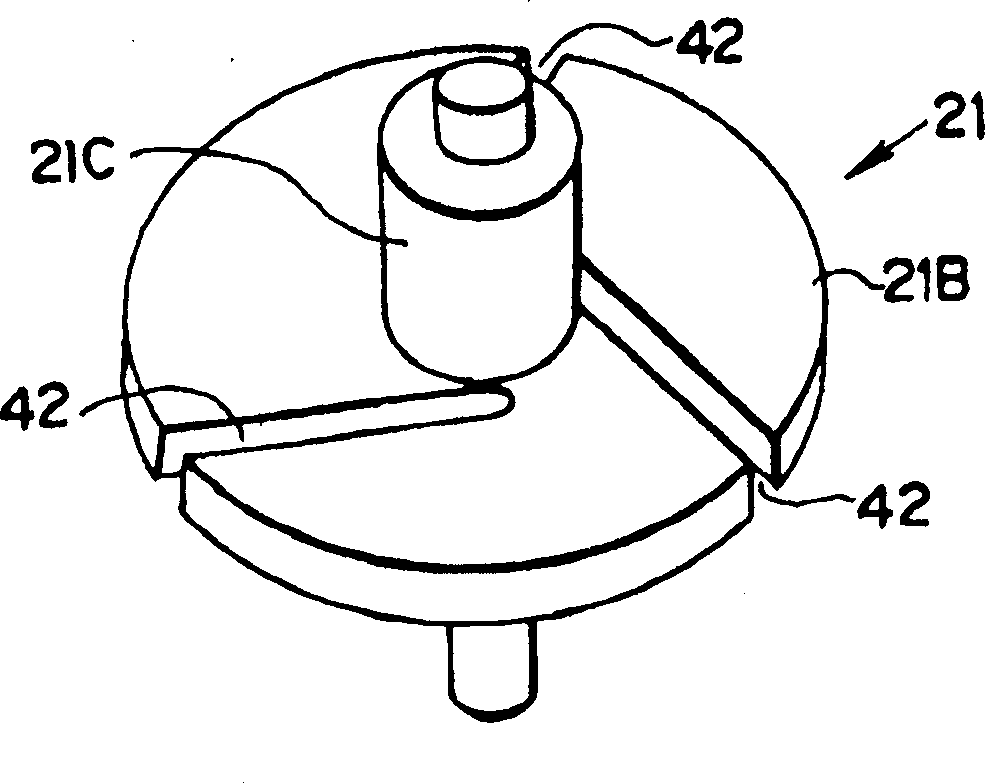

[0064] figure 1 is an enlarged sectional view of the main part of the fuel injection valve 40, figure 2 is a perspective view seen particularly from the attraction surface 23B side of the magnet core 23 in the fuel injection valve 40, image 3 is a perspective view of the armature 21, in the fuel injection valve 40, the configuration of the mutually opposing parts of the magnet core 23 and the armature 21 is the same as that of the already described fuel injection valve 1 ( Figure 8 ) are different.

[0065] especially if figure 2 As shown, a magnetic core radial gap 41 (radial gap) in the radial direction is formed on the side of the surface of the magnetic core 23 facing the armature 21 (attraction surface 23B side), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com