Pneumatic driver with valve kinematic speed adjustment

A technology driven by air pressure and moving speed, which is applied in the direction of valve operation/release device, valve device, valve details, etc., and can solve the problems of particle generation, self damage, good rate drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

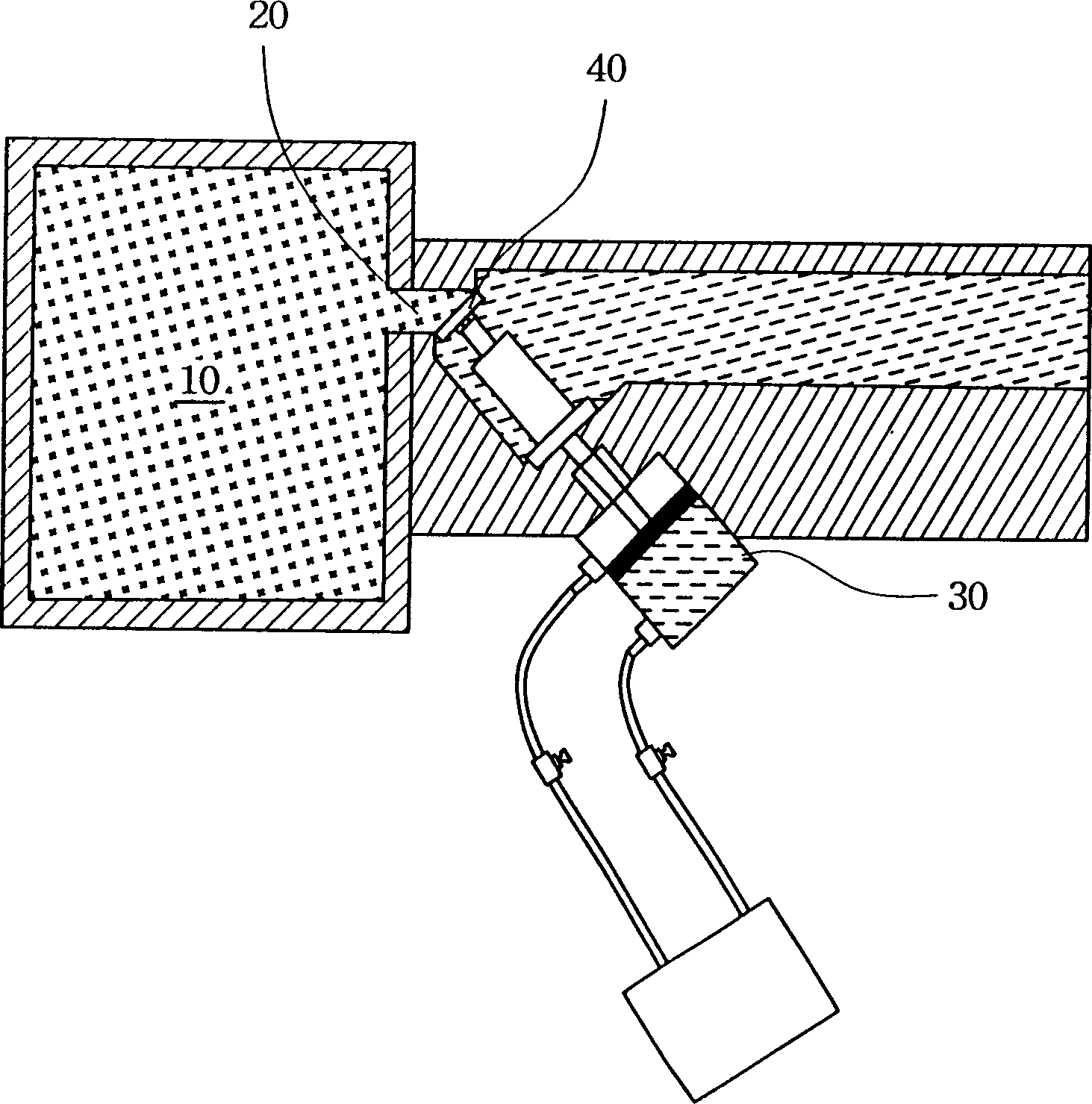

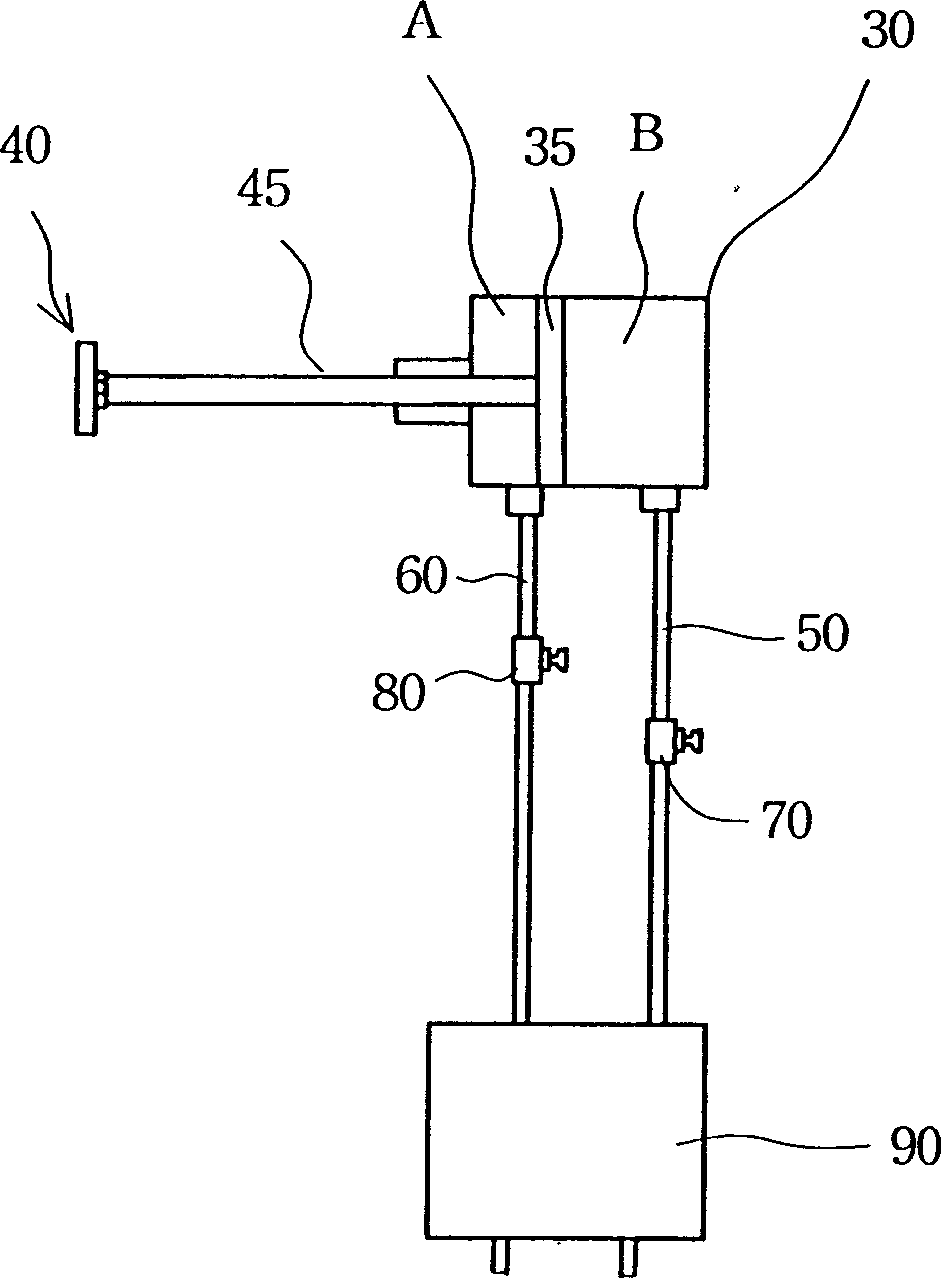

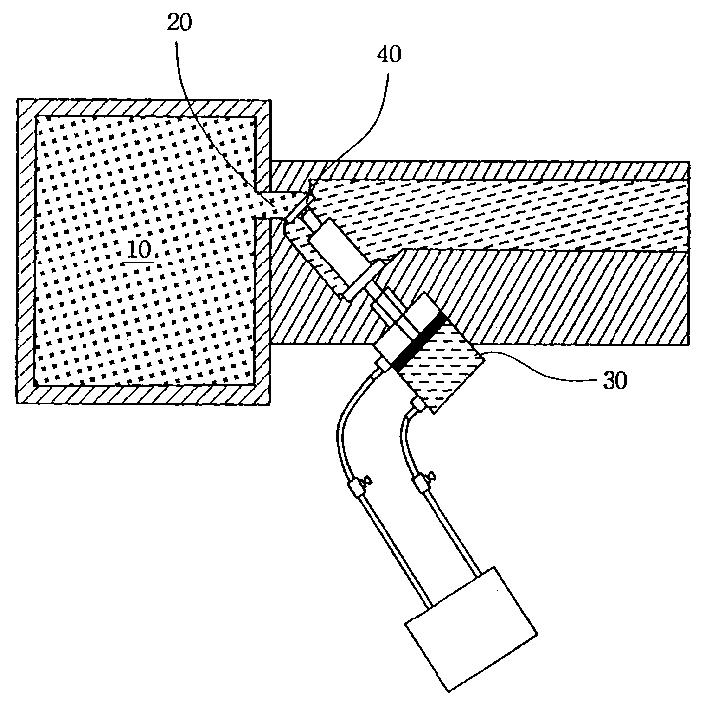

[0014] Please refer to figure 1 , which is a device diagram according to a preferred embodiment of the present invention. In the figure, the wafer port (Wafer Port) 20 of the reaction chamber (Process Chamber) 10 uses a pneumatic drive device to open and close the valve (Door) 40 . figure 2 for figure 1 An enlarged view of the pneumatic drive device. The above-mentioned pneumatic drive device includes a container body 30 in which a piston 35 is divided into a gas storage space A and a gas storage space B. The piston 35 passes through the opening of the gas storage space A through a long axis 45 Connect with valve 40. Each of the two gas containing spaces has an opening connection, the gas containing space A is connected to the gas conduit 60 , and the gas containing space B is connected to the gas conduit 50 . Both the gas conduit 50 and the gas conduit 60 are connected to a solenoid valve 90 , and a pressure regulating valve is installed between the container main body 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com