Axially adjustable thrust bearing for jet propulsion units

一种喷射推进、止推轴承的技术,应用在轴和轴承、用同步推进部件的传动装置、推进的动力传递等方向,能够解决效率降低、喷射推进单元故障严重等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

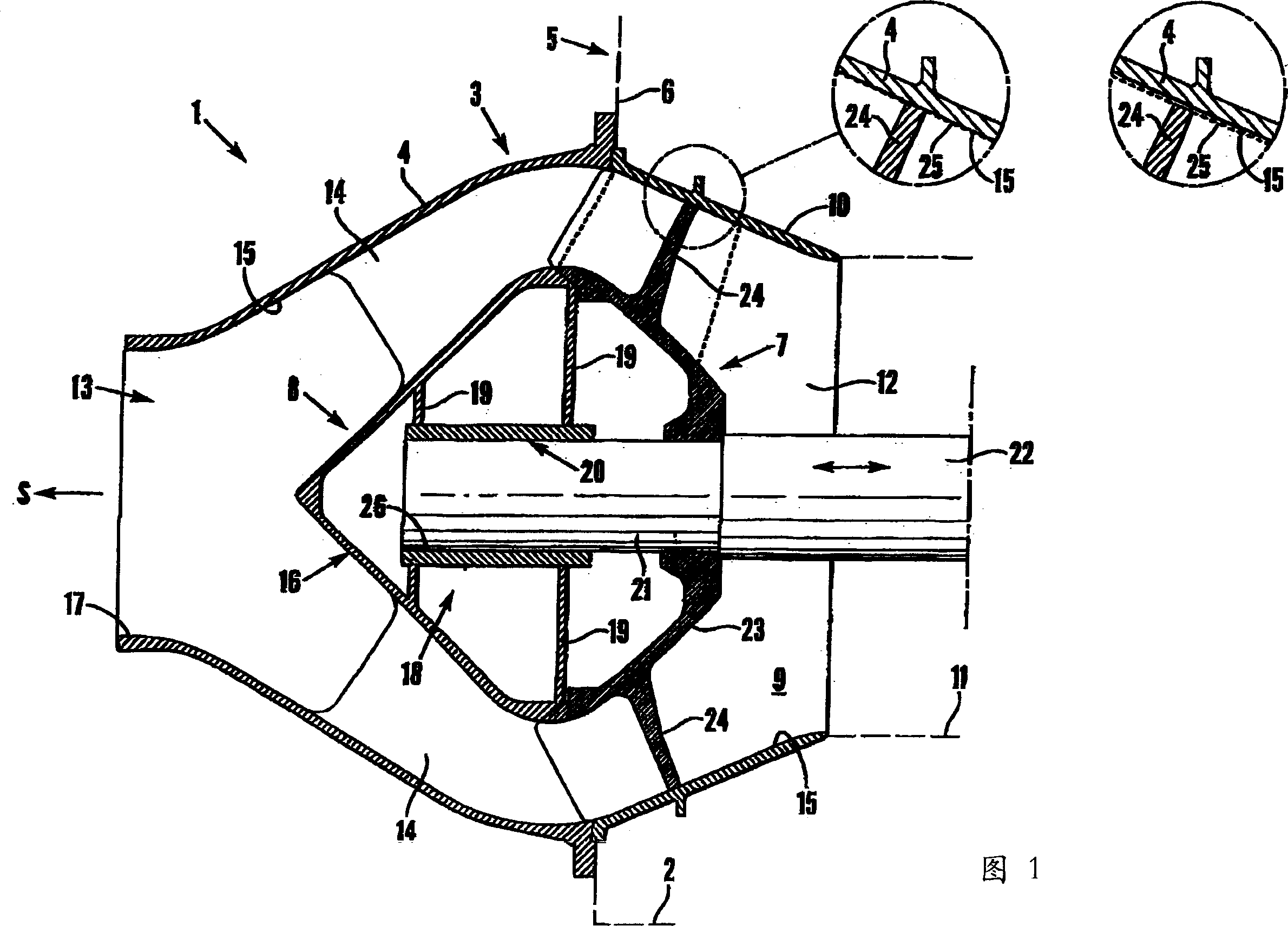

[0030] Reference is made to Figure 1 which schematically shows a longitudinal section of a jet propulsion unit 1 for propelling a watercraft. As an integral part of the watercraft 2, the jet propulsion unit 1 comprises an impeller pump 3 with a pump housing 4, comprising a front and a rear portion, mounted within the stern portion 5 of the hull of the watercraft 2, and typically Located at the transom stern 6 of the hull 2 or along the transom stern. Furthermore, the impeller pump 3 includes an impeller 7 which is rotatably journalled on the center of a hub shell 8 and which is fixedly mounted in an impeller chamber 9 in the impeller shell 4 .

[0031] The impeller shell 4 and its impeller chamber 9 form an expandable, conical and spherical pipe part 10, and communicate with the seawater flow pipe 11, and the flow pipe 11 extends obliquely upward from the water inlet (not shown in the figure) , the water inlet is arranged below the load line of the ship, and preferably at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com