Particle field total-field measurement process and apparatus based on laser sheet optical image-forming

A technology of laser sheet light and particle field, applied in measurement devices, instruments, etc., to avoid technical and financial problems, avoid analysis and requirements of followability and light scattering, and avoid interference problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

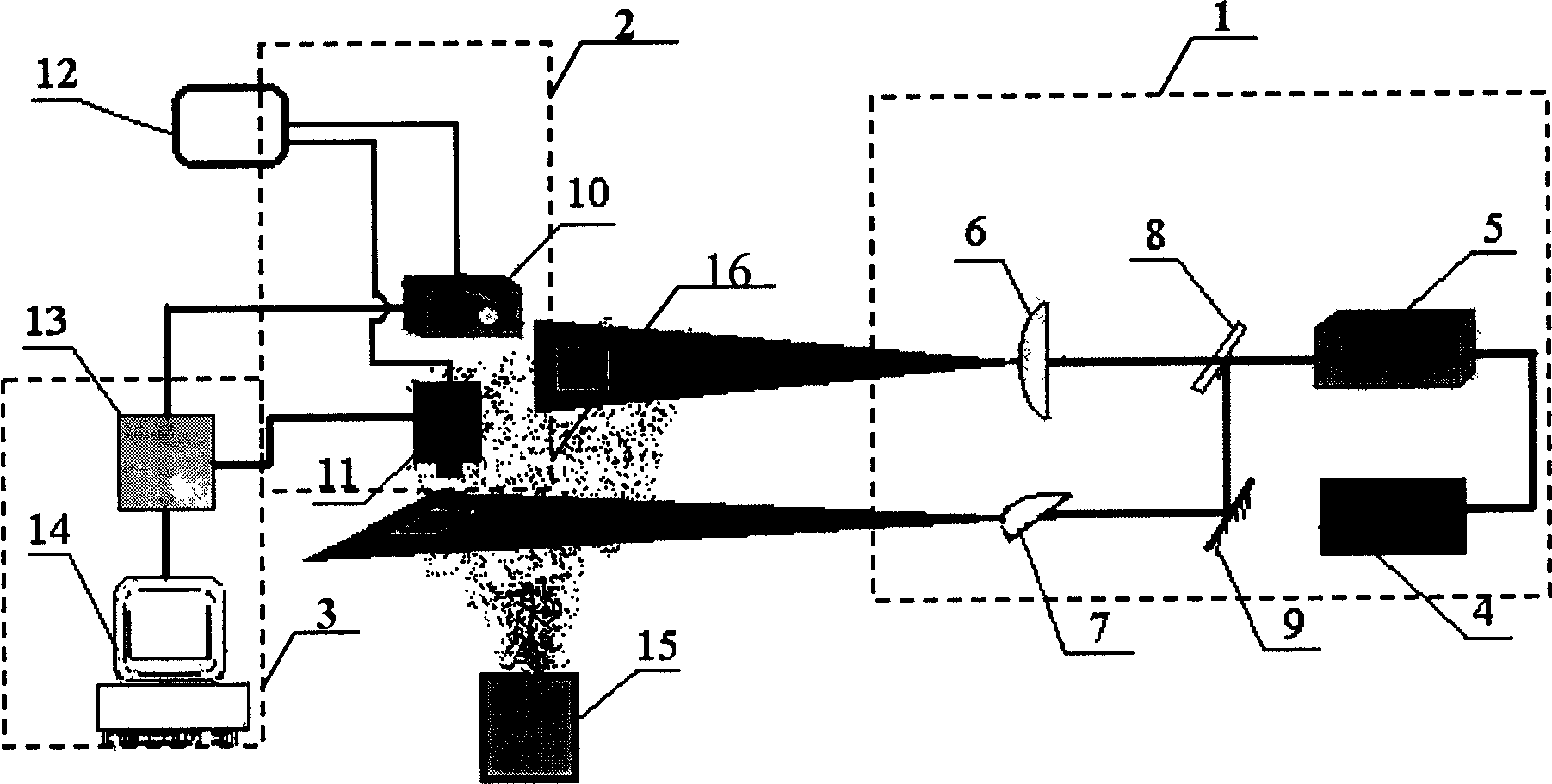

[0016] Embodiment 1: Measurement of particle size and velocity distribution of solid particles in two-phase flow field

[0017] In the present embodiment, the laser sheet optical system 1 is made up of a laser power supply 4, a semiconductor laser 5 with a wavelength of 650nm, two cylindrical lenses 6 and 7, a beam splitter 8 and a mirror 9, and the beam splitter 8 is placed in the laser 5 At about 200mm on the optical axis of the laser beam splitter 8, the cylindrical lens 6 is placed at about 150mm on the optical axis of the transmitted beam after the laser passes through the beam splitter 8, and the mirror 9 is placed on the optical axis of the split beam after the laser passes through the beam splitter 8. At 250mm, the cylindrical lens 7 is placed at about 250mm on the optical axis of the light beam after the split beam is reflected by the reflector 9; the digital imaging system 2 adopts two CCD cameras 10 and 11 with a resolution of 1024×768, wherein the CCD camera 10 Per...

Embodiment 2

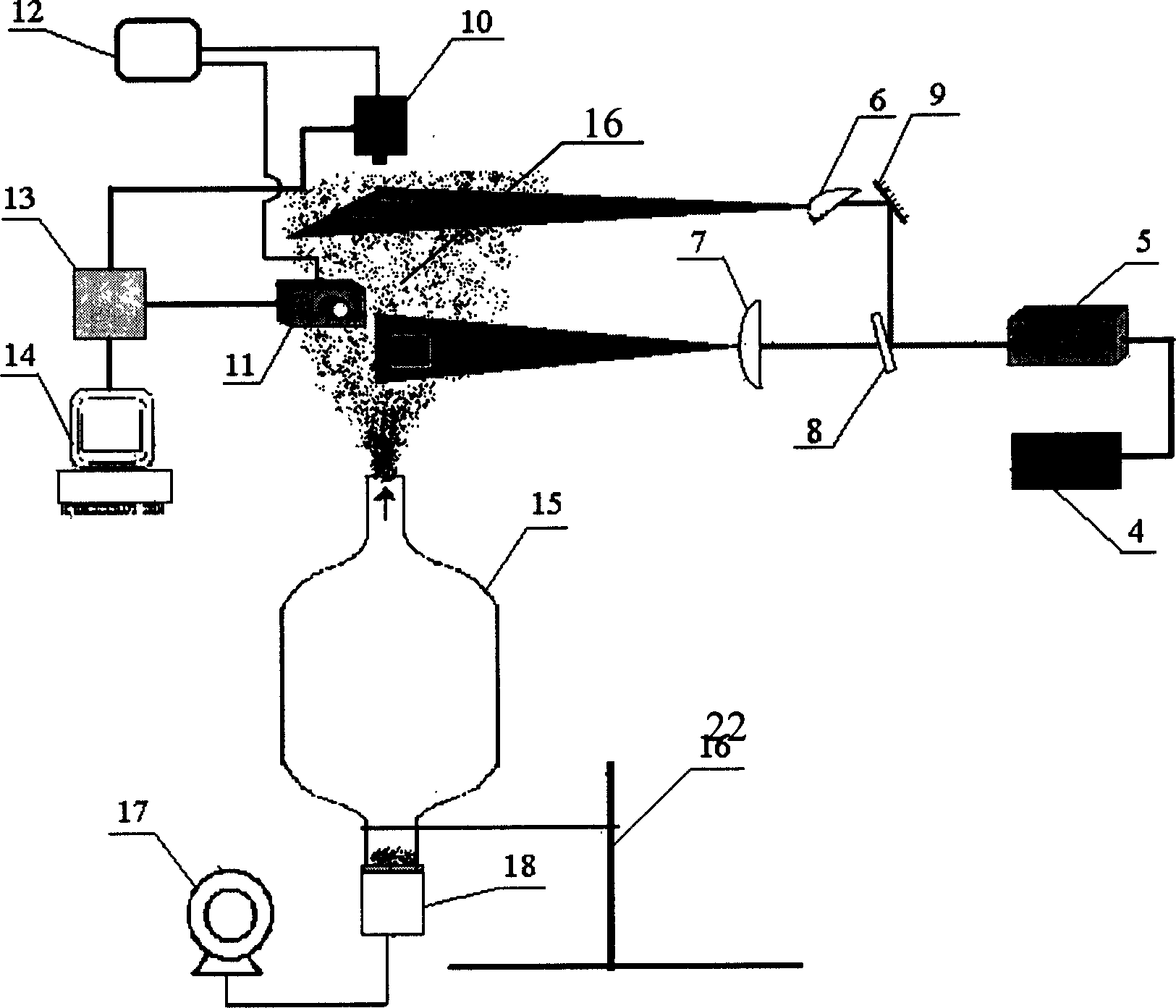

[0021] Embodiment 2: Measurement of the particle size of liquid particles in the gas-liquid two-phase flow field (fine water mist droplet flow field)

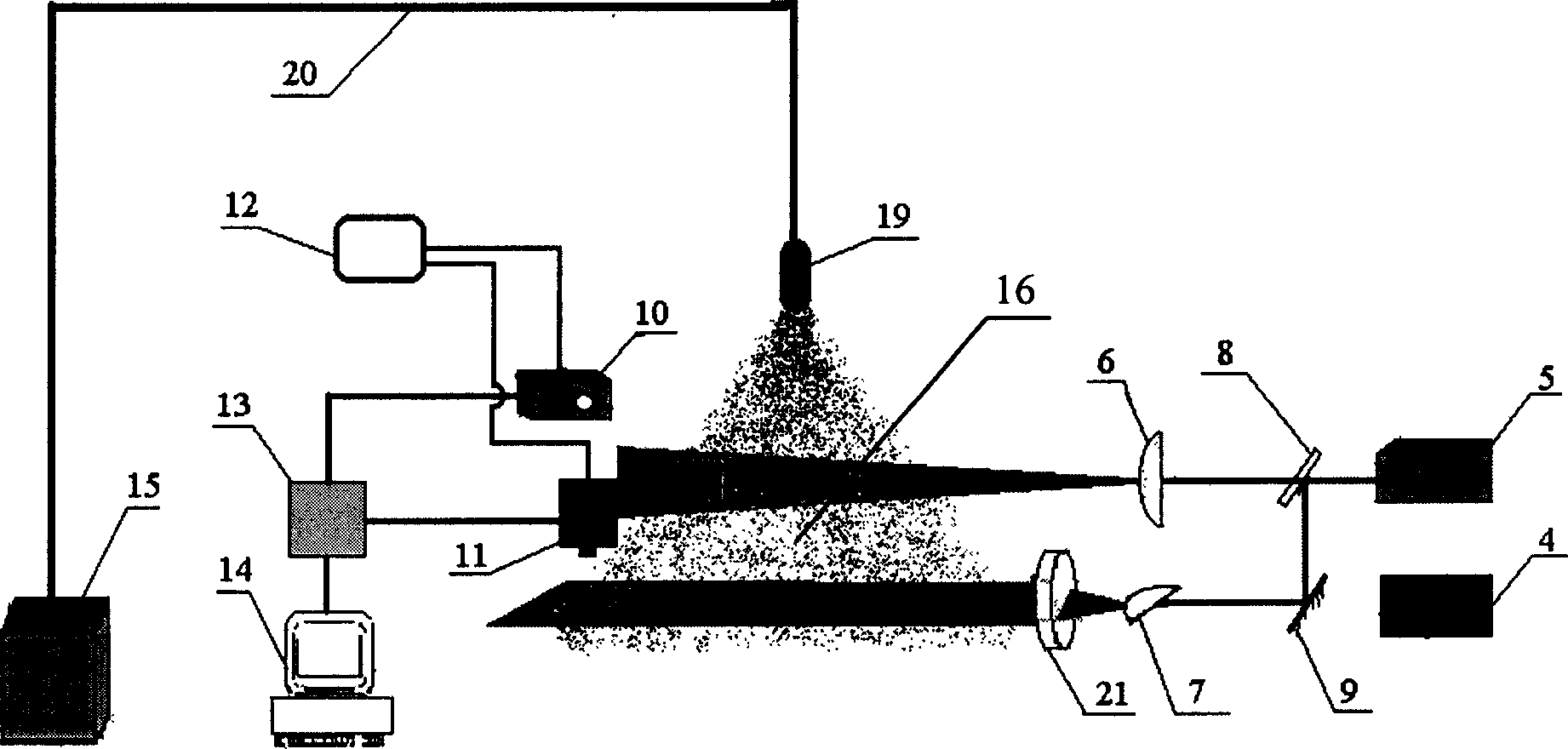

[0022] The composition and layout of the measuring device in this embodiment are basically the same as in Embodiment 1, the difference is that in this embodiment the sheet light produced by the cylindrical lens 6 is parallel to the direction of the flow field, while the sheet light produced by the cylindrical lens 7 is vertical In the direction of the flow field; in the present embodiment, a collimator lens 21 with a diameter of 300mm is arranged at about 200mm on the transmission light path of the cylindrical lens 7, and the purpose is to collimate the fan-shaped sheet light into parallel sheet light, so that the laser sheet light The light intensity distribution is as uniform as possible.

[0023] In this embodiment, the two-phase or multi-phase flow field generating device 15 is a combination system of a water storage device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com