Dust absorption head for electric vacuum cleaner and electric vacuum cleaner

A vacuum cleaner and vacuum head technology, applied in vacuum cleaners, suction nozzles, applications, etc., can solve the problem that the dust collection range of the floor suction head 210 becomes smaller, the floor suction head 210 cannot successfully complete the dust collection, and the suction head with a brush 250 angle instability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, a first embodiment of the present invention will be described with reference to the drawings. It should be noted that the following embodiment is only an example of embodying the present invention, and the scope of rights of the present invention is not limited thereto.

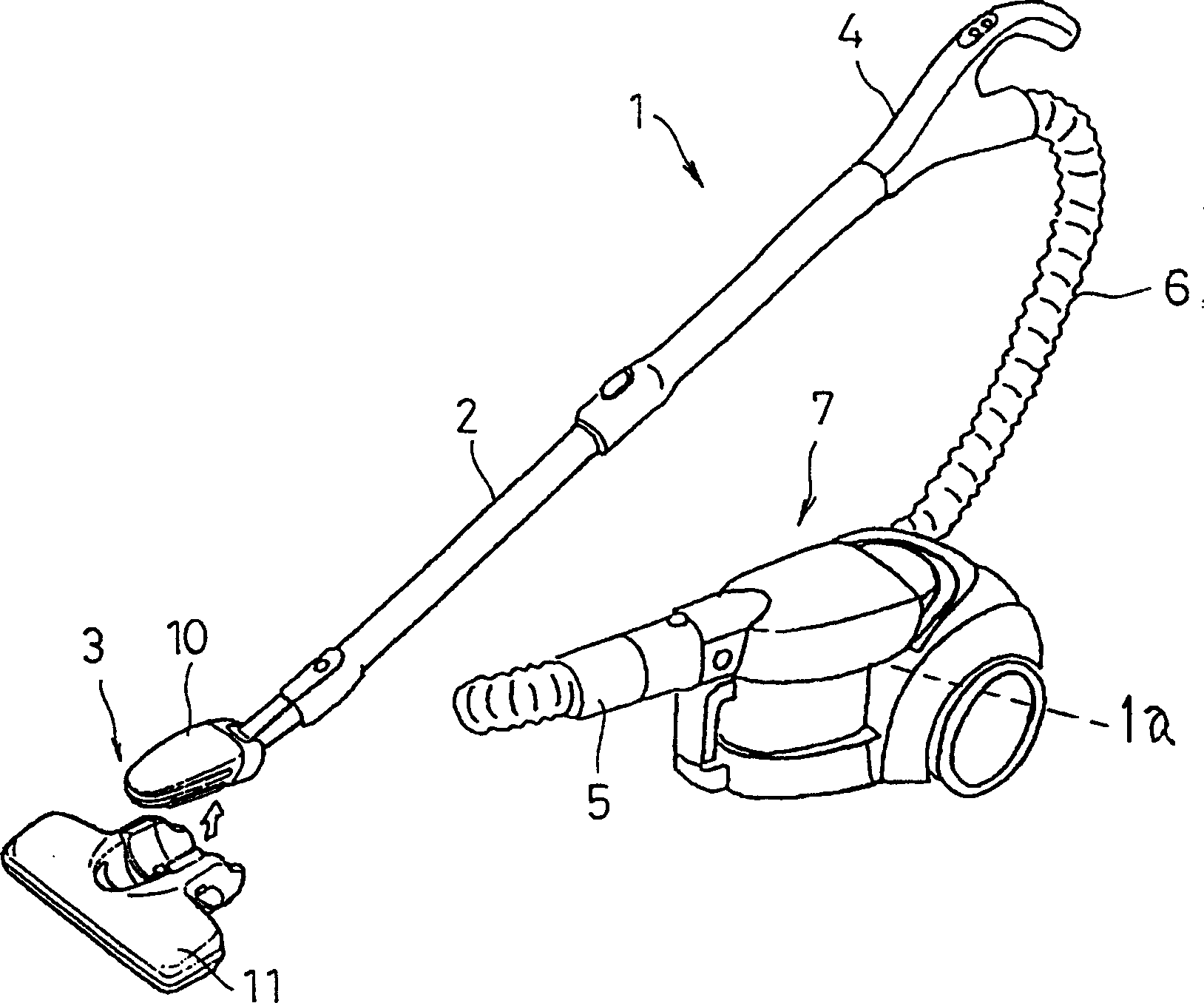

[0033] This example figure 1 As shown in , the figure shows a ground mobile electric vacuum cleaner 1 and a dust suction head 3 as its dust suction device. The structure of this electric vacuum cleaner 1 is as follows. The dust suction head 3 is mounted on the front end of the extension tube 2 in a detachable manner, the extension tube 2 is connected with the handle (hand lever) 4, and the hose 6 extending from the handle 4 passes through the hose connector 5 and The vacuum cleaner main body 7 is connected. An electric blower 1a is provided inside the main body 7 of the vacuum cleaner.

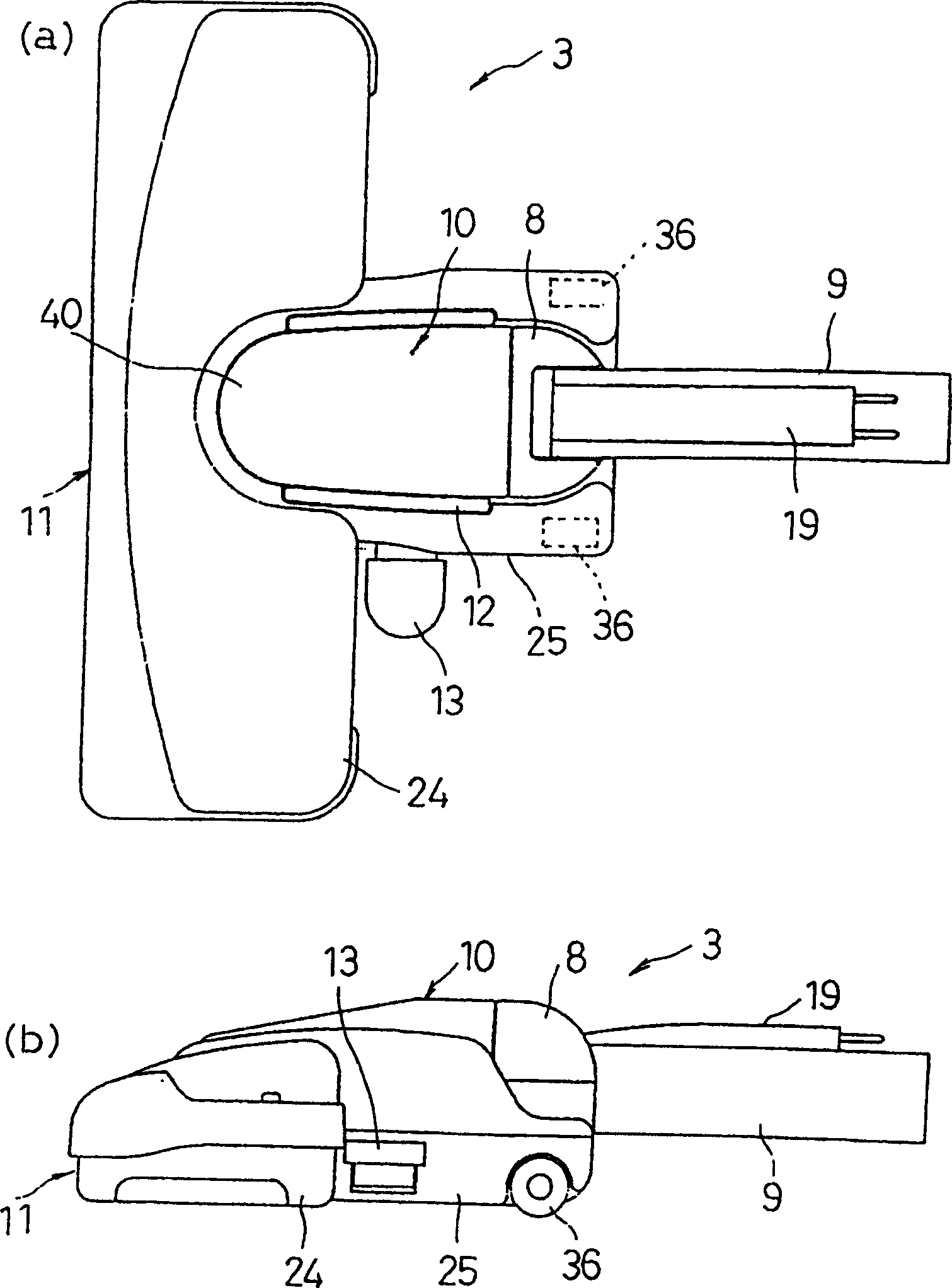

[0034] Above-mentioned suction head 3 such as figure 2 (a) and (b) are composed of a small suction head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com