Plastic bag with zippered small bag

A technology for plastic bags and zippers, applied in the field of plastic bags, can solve the problems of blocking zippers and inconvenient removal of fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, referring to the accompanying drawings, an embodiment of the plastic bag of the present invention will be described.

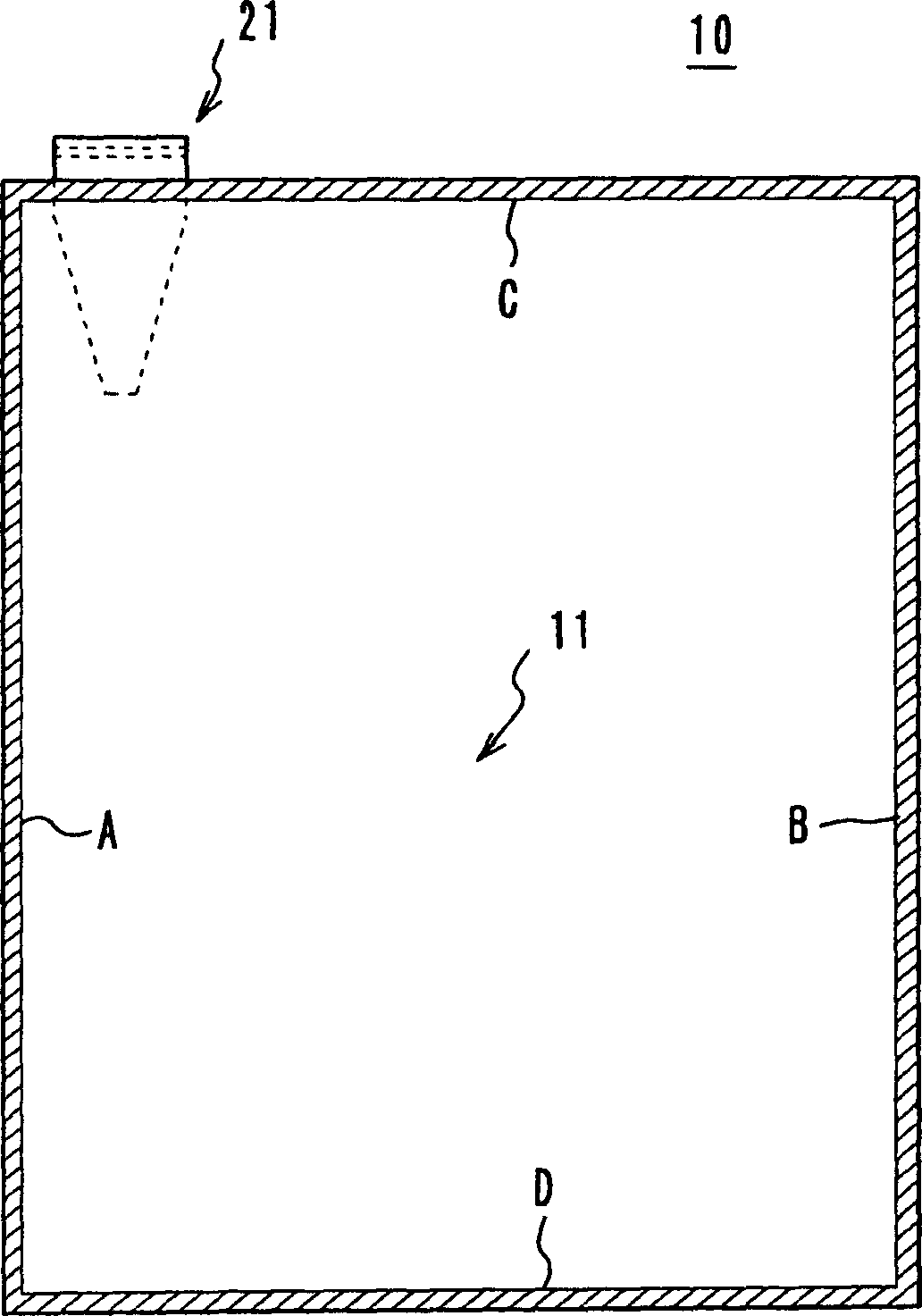

[0020] figure 1 It is a front view of the plastic bag which concerns on one Embodiment of this invention. The bag 10 is composed of a large bag 11 and a nozzle-shaped small bag 21 formed of a plastic film, respectively. The big bag 11 is a bag made as a known welding bag in the past, and a raw material film is folded into two, or two raw material films are overlapped, and its four sides are welded (such as figure 1 Parts A, B, C, and D indicated by the slashes in ) are formed. Also, the lower edge portion D is welded after filling the large bag 11 with a fluid.

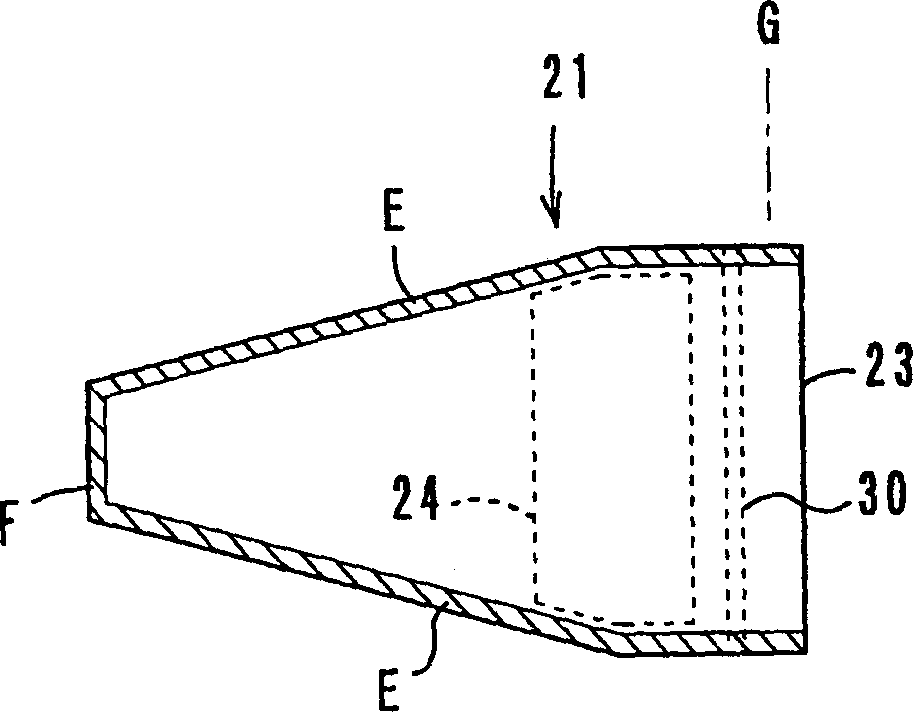

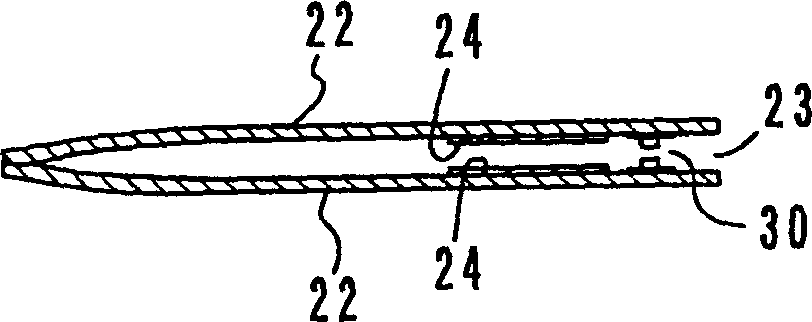

[0021] The small bag 21 is formed by inserting and welding between the films of the upper welding part C of the large bag 11 . Such as Figure 2A and Figure 2B As shown, the two side parts E, E and the end part F of the two heat-welding plastic films 22 and 22 are welded (sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com