Electric wire connector

A connector and wire technology, applied in the field of wire connectors, can solve problems such as poor operability and poor operability, and achieve the effects of preventing misoperation, preventing falling off, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

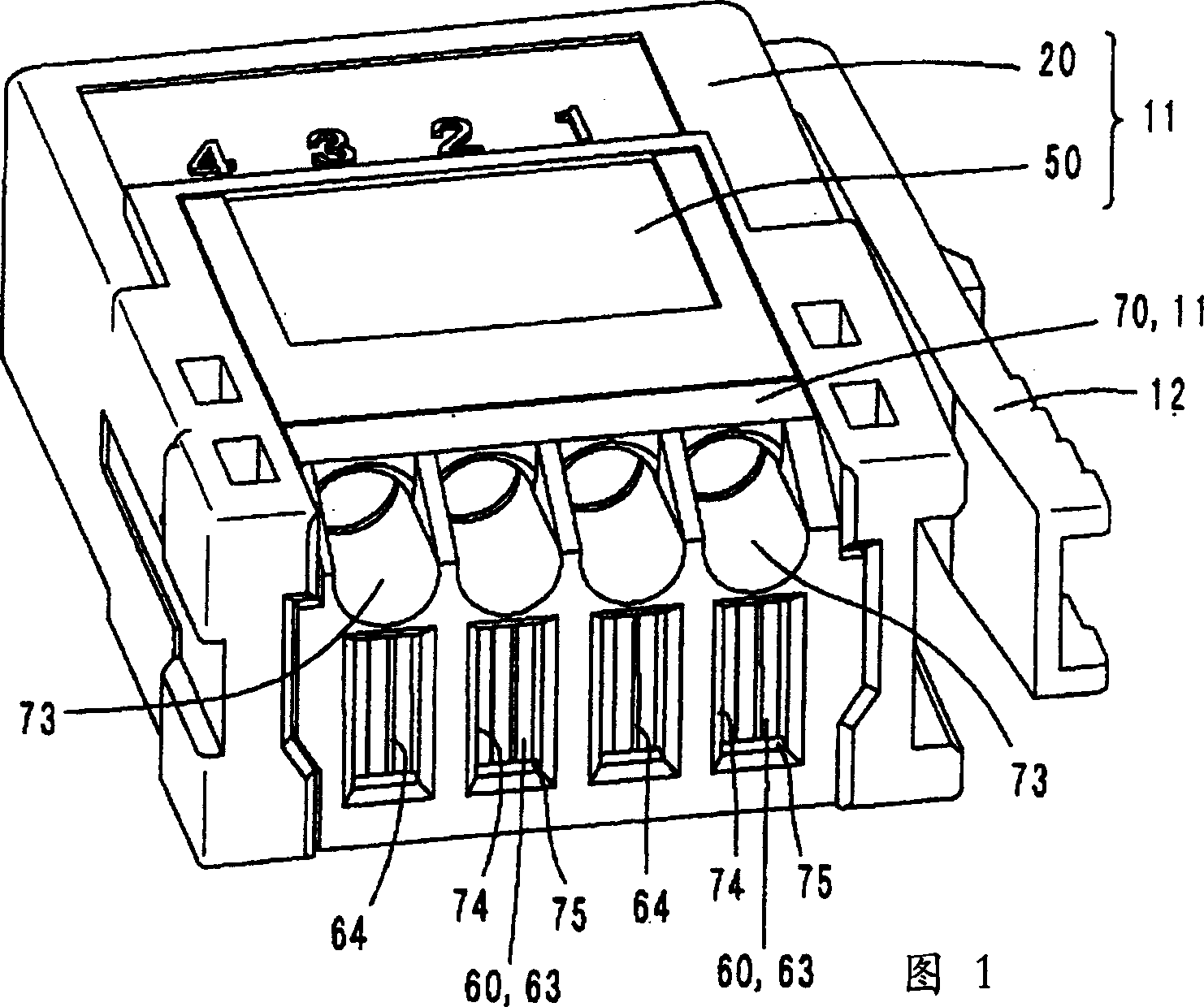

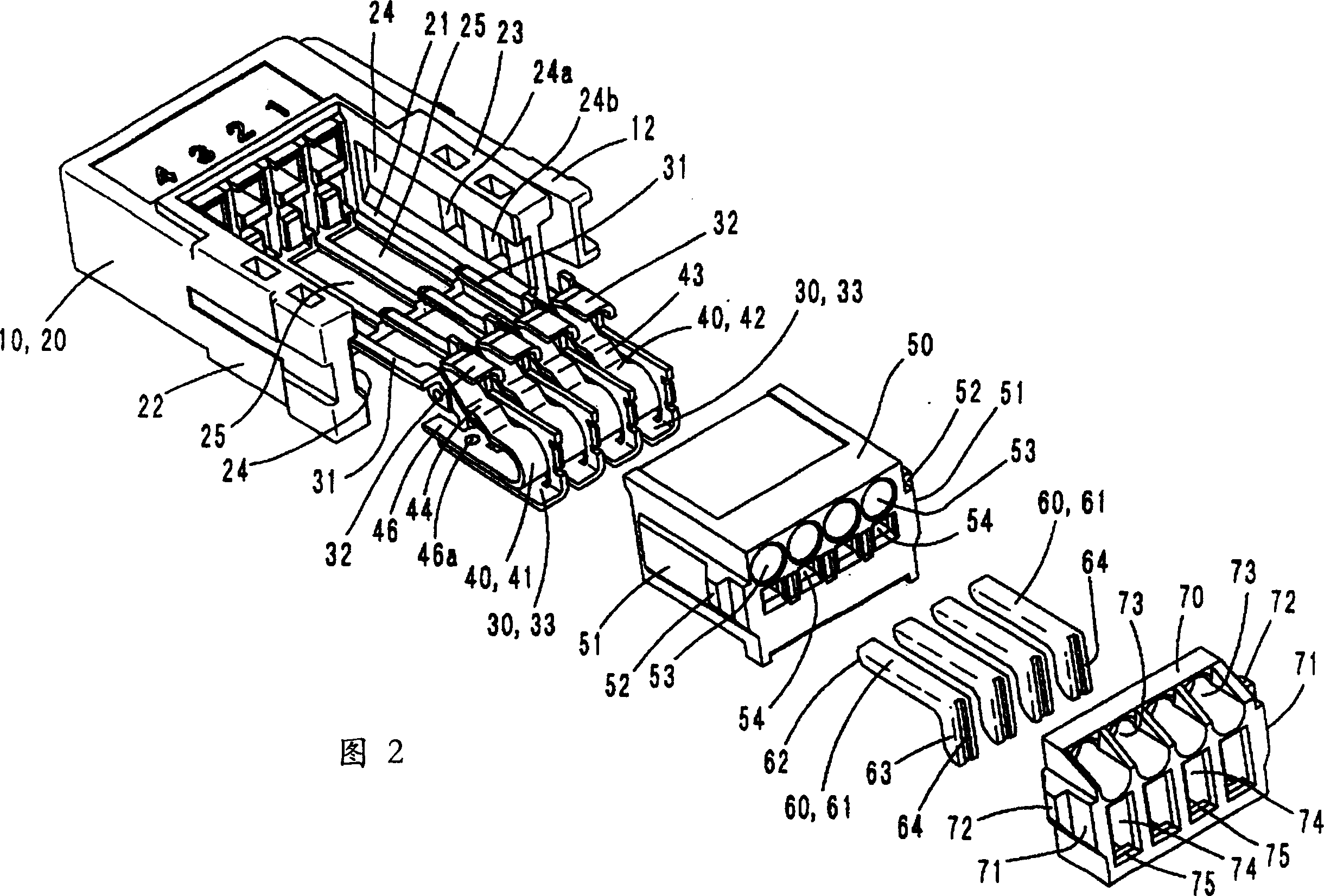

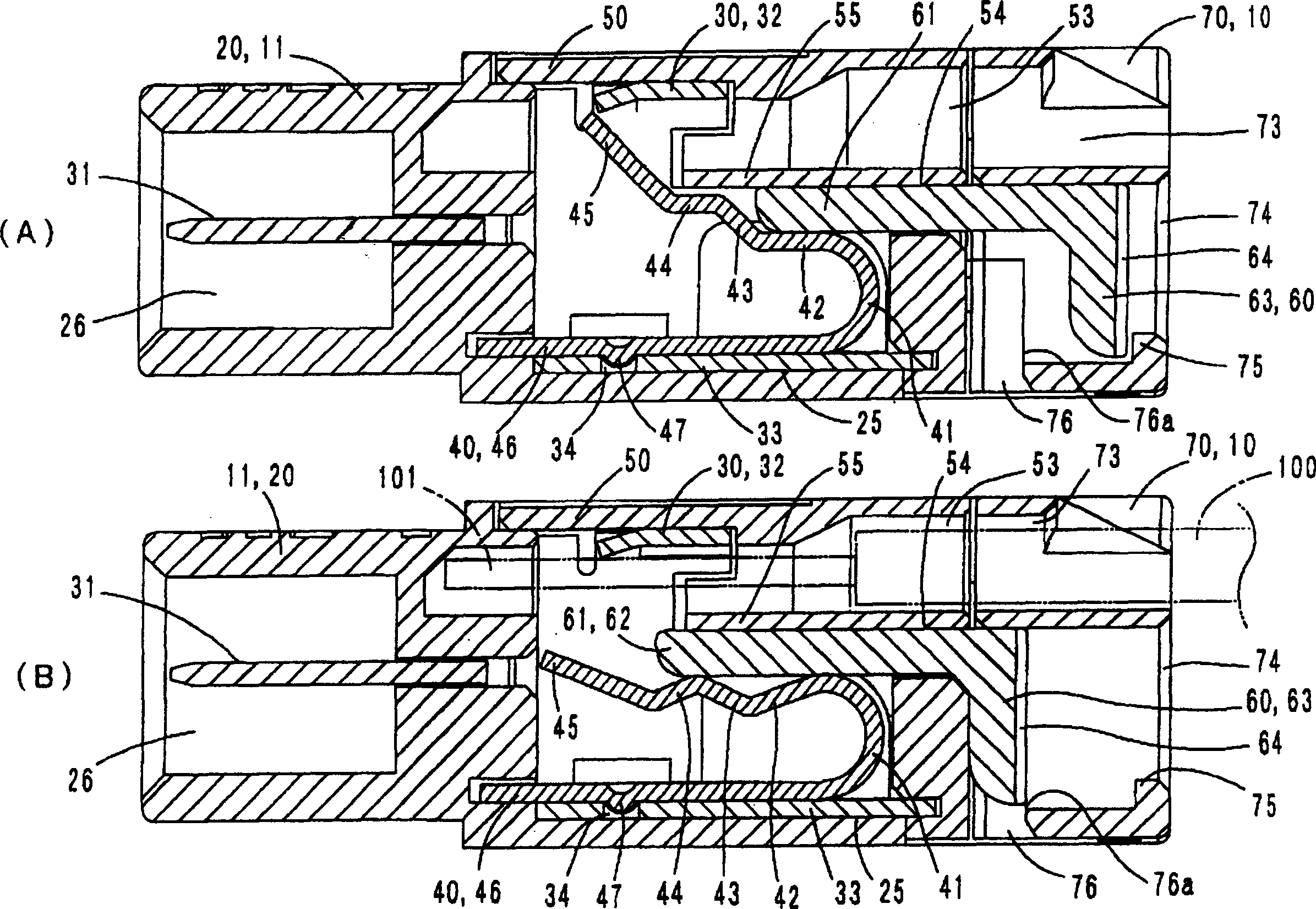

[0027] The following according to Figure 1 to Figure 8 Examples of the present invention will be described.

[0028] The first embodiment of the present invention is shown in Fig. 1 to Figure 4 Shown is the situation applicable to the wire connector 10 .

[0029] The wire connector 10, as shown in FIG. 2 , is equipped with a metal connector 30 , a leaf spring 40 and an operating rod 60 in an internal space formed by installing a cover 70 on a box body 11 composed of a housing 20 and a base 50 . . In addition, 12 is a lock lever.

[0030] The housing 20 is a resin molded product in which a concave portion 21 capable of engaging a base 50 and a cover 70 described later is provided on one side thereof. The casing 20 has guide grooves 24 , 24 formed on the inner surfaces of the arm portions 22 , 23 on both sides, respectively, and engaging recesses 24 a , 24 b are formed in the guide grooves 24 , respectively. The engagement recesses 24a, 24b are used to determine the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com