Counter-current contact flocculating settling apparatus

A contact flocculation and reverse flow technology, applied in the sedimentation tank and other directions, can solve the problems of unsatisfactory sedimentation efficiency and sedimentation effect, the turbidity of the effluent from the sedimentation tank cannot be further reduced, and leakage, etc. good precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

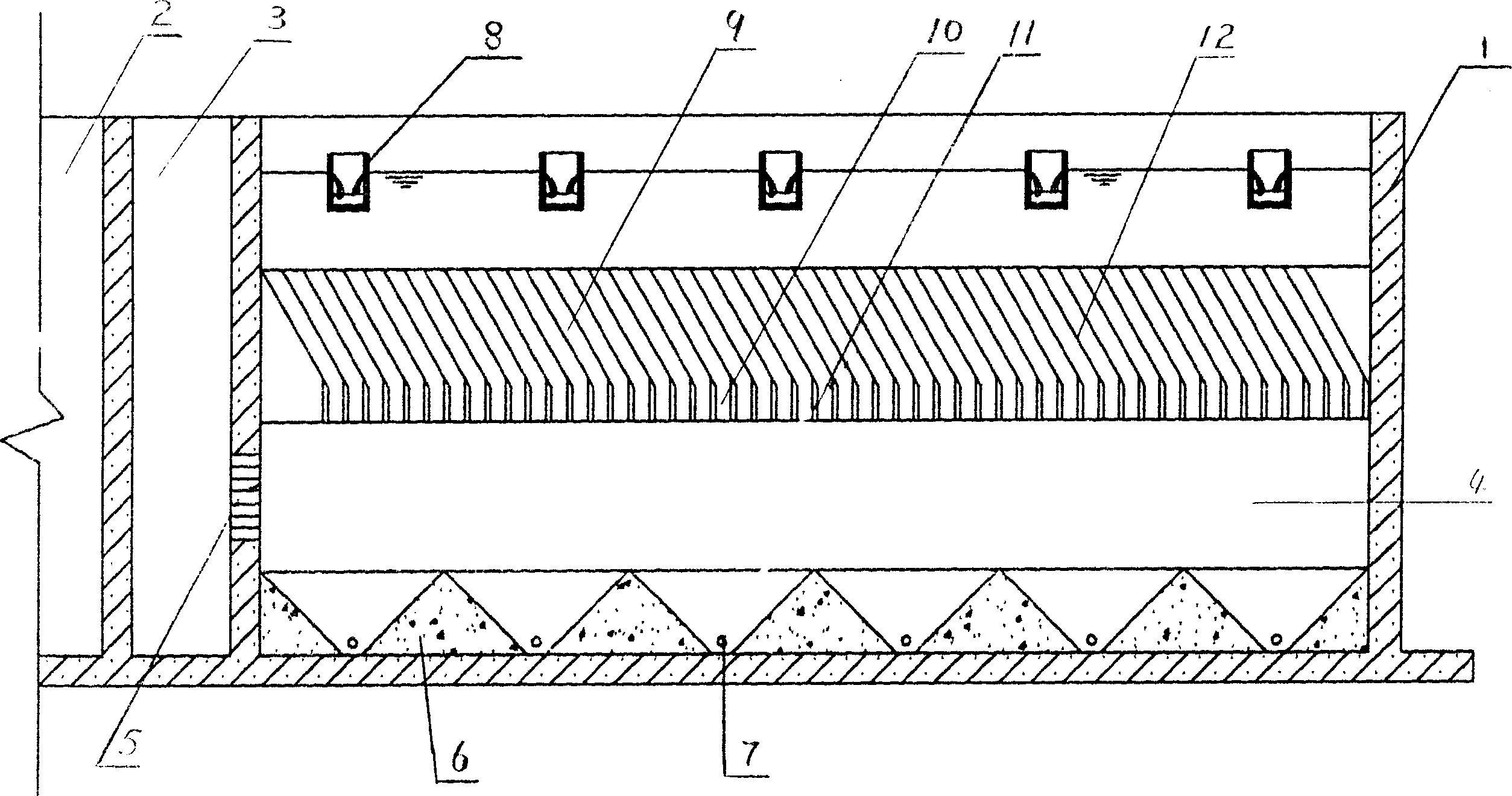

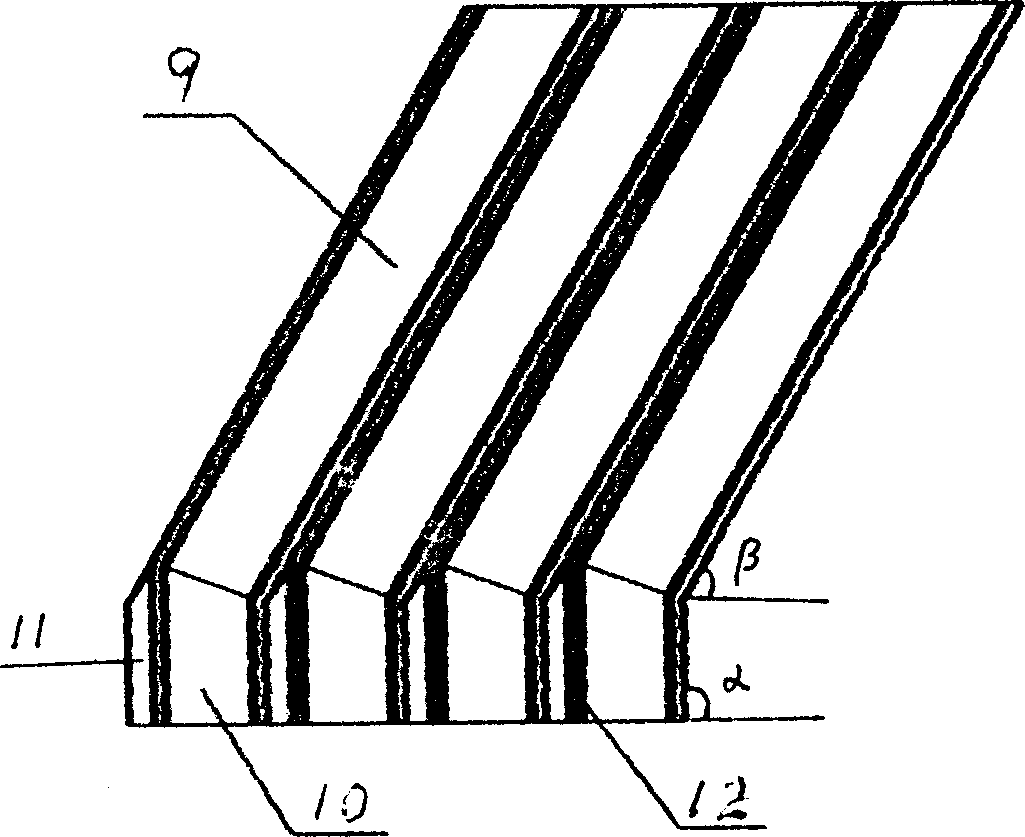

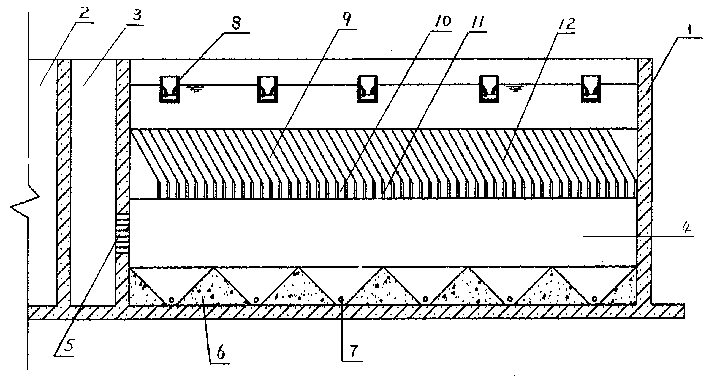

[0023] The liquid flows upward in the sedimentation tank, and flows out through the rectification section and the inclined plate area. The well-reacted particles settle to the surface of the sloping plate according to the precipitation mechanism and slide down the sloping plate to the lower part of the sloping plate area. In the lower part of the inclined plate area and in the rectification section, the particles will be dragged by the upward water flow, and cannot slide down the rectification area to leave the equipment. Only the particles with larger particle size and density can leave the suspension area through the jacking action of the lower liquid flow, and settle to the bottom of the sedimentation tank for discharge.

[0024] After the mixing and reaction process, the liquid-solid two-phase mixed liquid passes through the water distribution section of the sedimentation tank, flows upward into the equipment, and flows into the space formed by the inclined plate protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com