High efficiency and easy diffusive negative ion generator

A negative ion generator and ion emission head technology, applied in the field of electronics, can solve the problems of rising failure rate, poor use effect, and breakdown of turns in transformers, etc., to solve the problem of low ion escape efficiency, improve use effect, and eliminate the need for The effect of short circuit protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings.

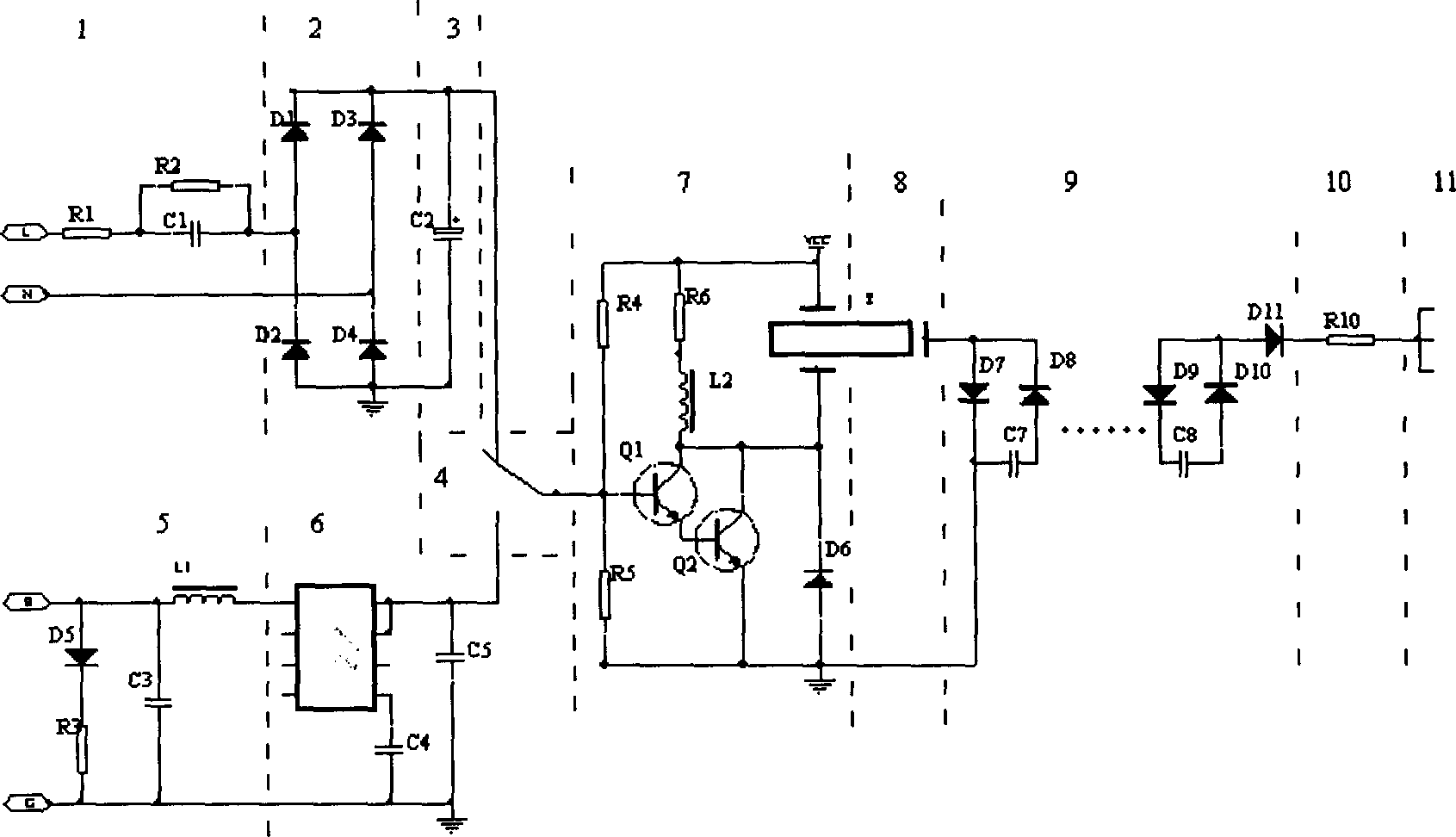

[0021] As we all know, the working principle of negative ion generator is: use high voltage electric field to ionize air to generate (positive) ions, and the working voltage required for the generation of ions is from thousands of volts to tens of thousands of volts. In order to ensure personal safety and avoid possible contact with high-voltage parts, the negative (positive) ion generator is generally placed in an airtight casing, and the negative ions produced by the negative ion generator escape through a specially set window.

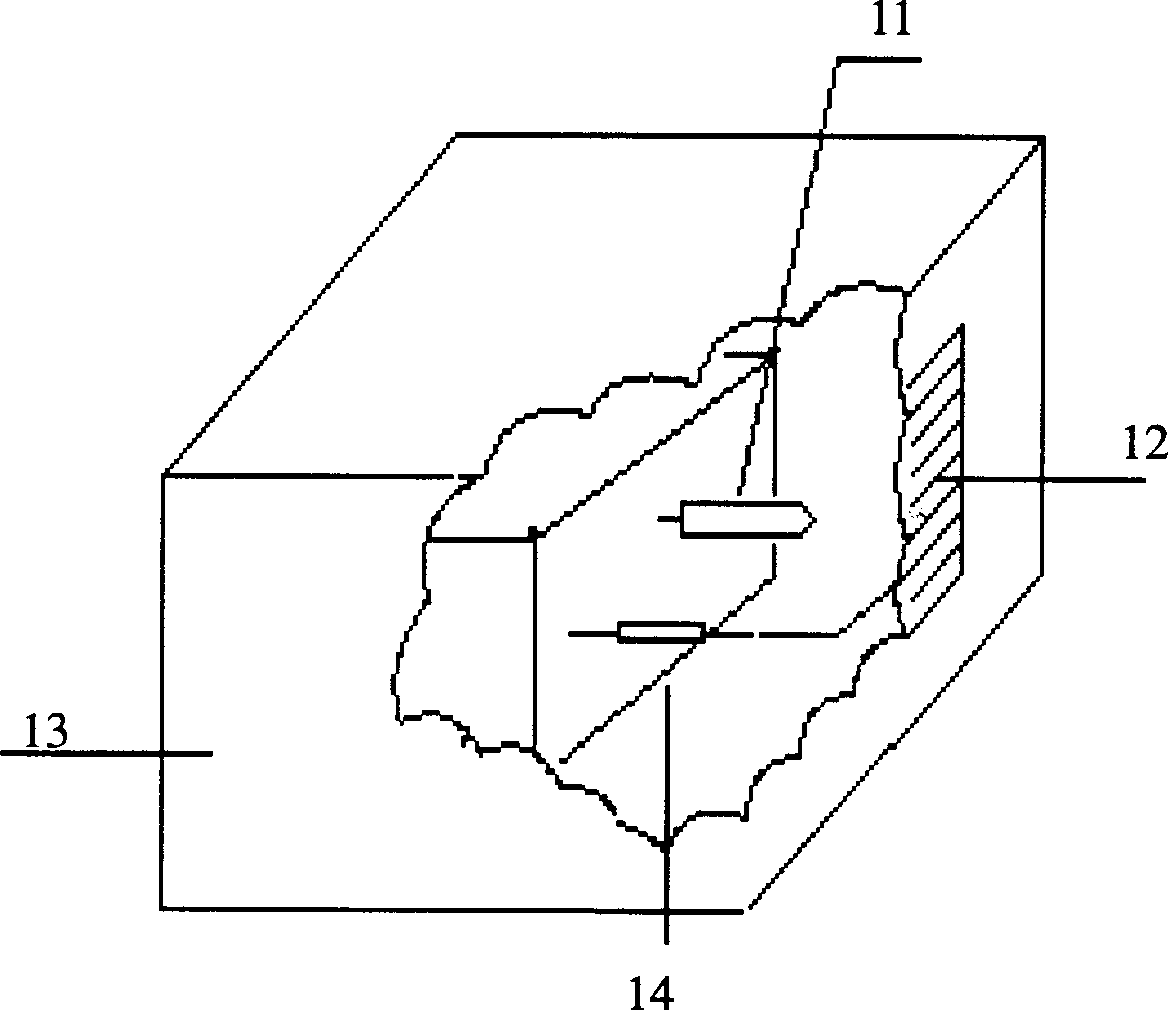

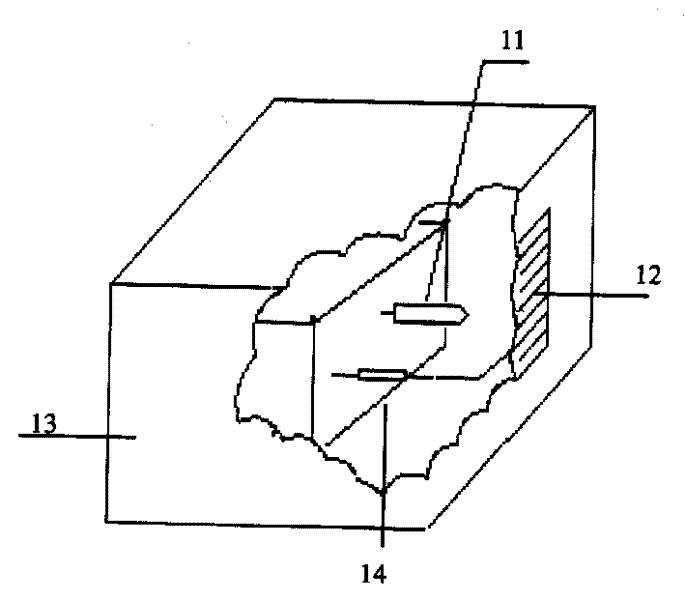

[0022] As shown in Fig. 1, the present invention is made up of casing, movement circuit, ion emission head 11, discharge resistance 14, casing is made up of casing 13 and conductive protection grid 12, is connected on the conductive protection grid 12 At a certain potential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com