Exosure method and device

An exposure method and exposure device technology, applied in optics, optomechanical equipment, nonlinear optics, etc., can solve the problem that patterns cannot be superimposed on a predetermined position with good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

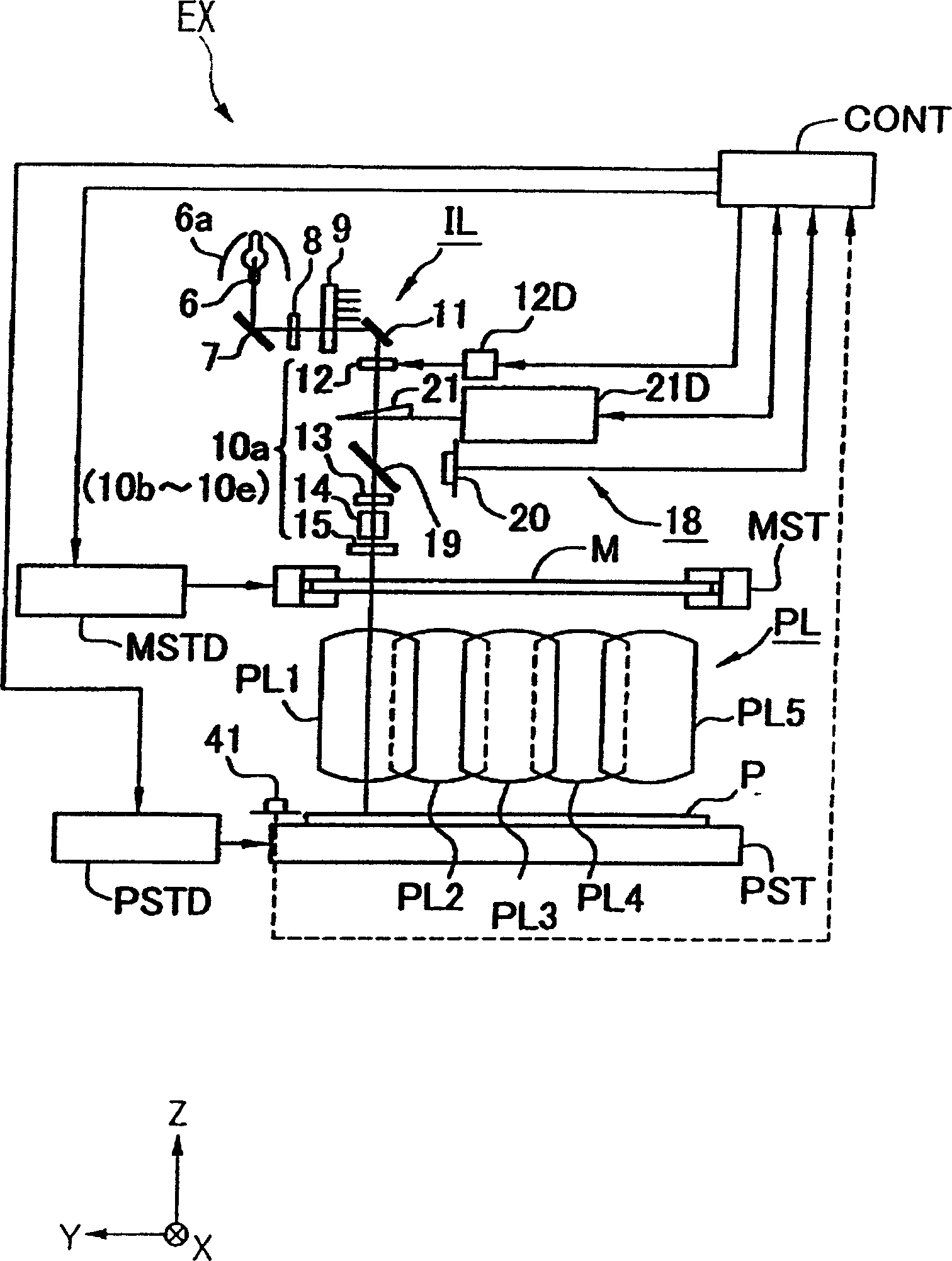

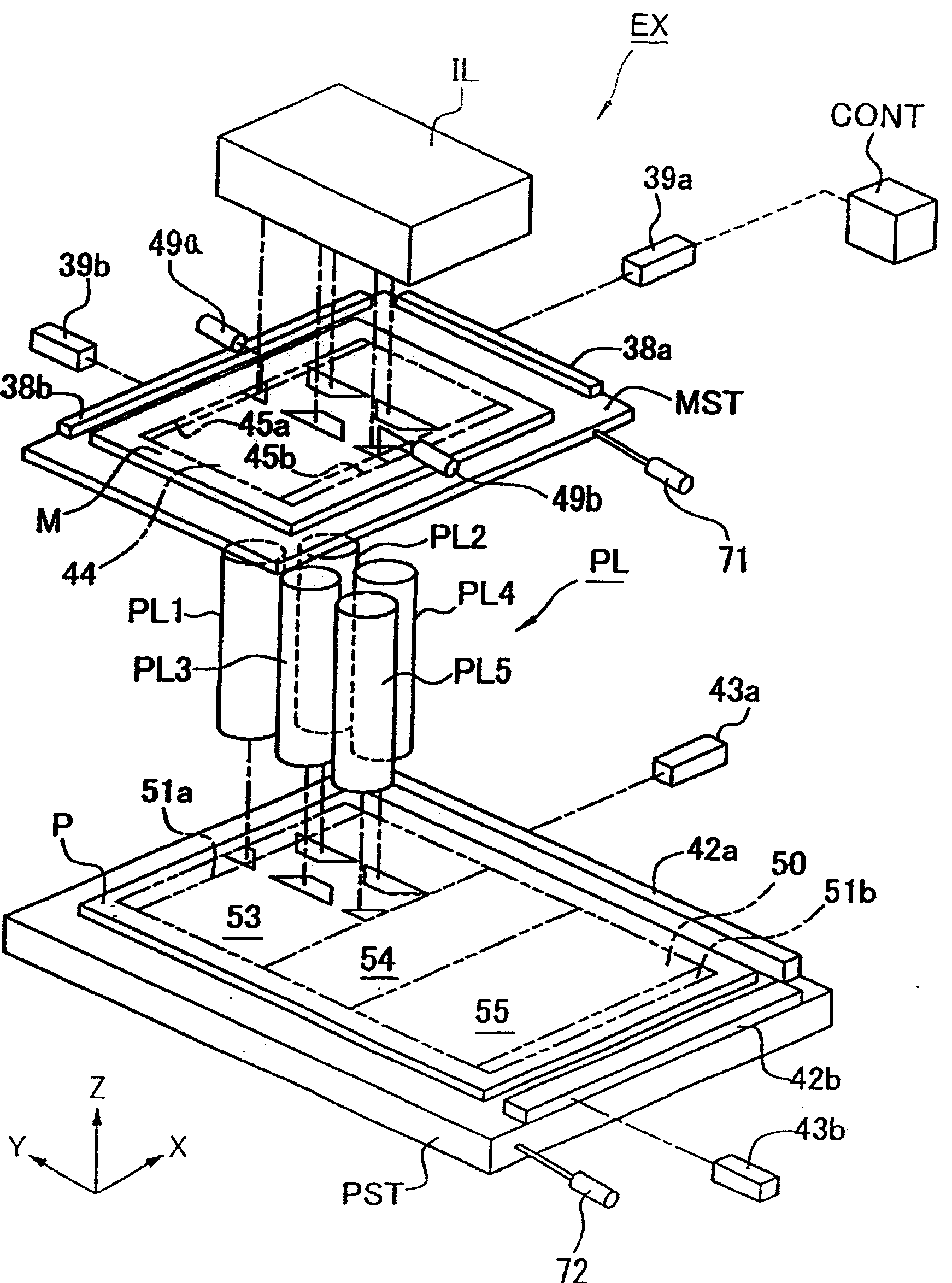

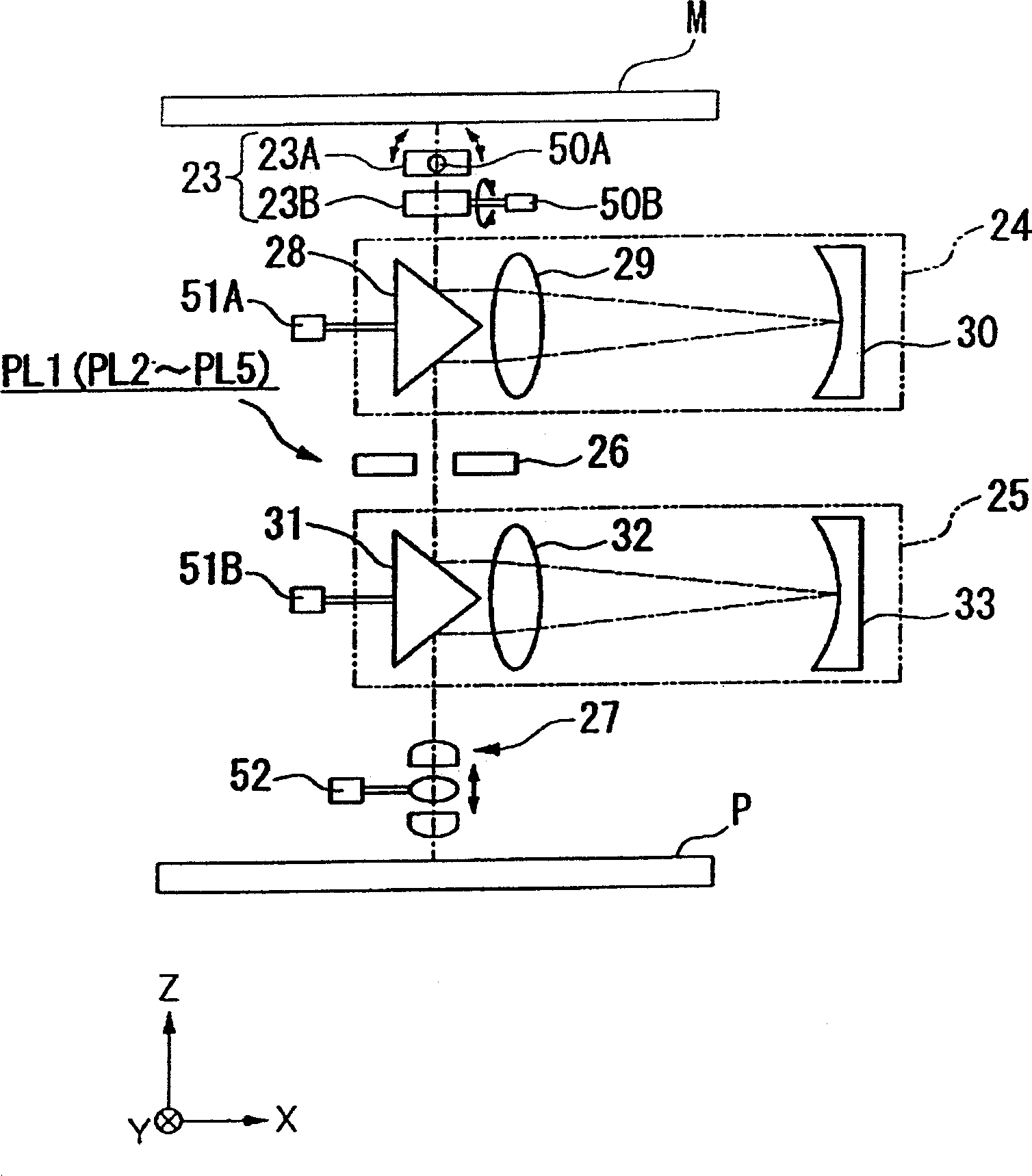

[0046] Hereinafter, the exposure method and exposure apparatus of this invention are demonstrated, referring drawings. figure 1 A schematic configuration diagram showing an embodiment of the exposure apparatus of the present invention, figure 2 for figure 1 rough oblique view of .

[0047] exist figure 1 and figure 2 The exposure apparatus EX includes an illumination optical system IL, a mask machine MST, a plurality of projection optical systems PL1 to P5, a substrate machine PST, mask side laser interferometers 39a, 39b, and substrate side laser interferometers 39a, 39b. Among these, illumination optical system IL has several illumination system elements (Module) 10a-10e which illuminate mask M with exposure light. The mask station MST supports the mask M. Several projection optical systems PL1-PL5 are arrange|positioned so that it may correspond to each illumination system element 10a-10e, and project the image of the pattern of the mask M illuminated with exposur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com