Portable washer

A portable, washing machine technology, applied in washing devices, textiles and papermaking, household appliances, etc., can solve problems such as no practical application, and achieve the effect of easy cleaning, saving transmission coupling structure and watertight structure, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0025] Fig. 1 illustrates the structure of the first kind of portable electric washing machine 1 and its cooperation with the common nominal 22L portable round plastic bucket 2 in the market. The electric washing machine 1 is made up of stirring rod 3, motor-reducer device 4, timer 5, power cord 6 and housing 7. The housing 7 encloses the motor-reducer device 4 and the timer 5 and their electrical connections according to safety designs such as anti-shock and splash-proof (IPX4) stipulated in the national standard GB4706.1. The shaft of the motor—reducer device 4 stretches out from the center of the lower part of the housing 7 through the sealing ring. The power cord 6 and the control shaft of the timer 5 are also drawn out from the side of the housing 7 through the seal ring. Bucket 2 is 35cm in depth, with an inner diameter of 32cm in the upper part and a downward taper of 5°. The end face of the housing 7 facing the bucket is a circle with a diameter of 31.5 cm, and the p...

no. 2 Embodiment

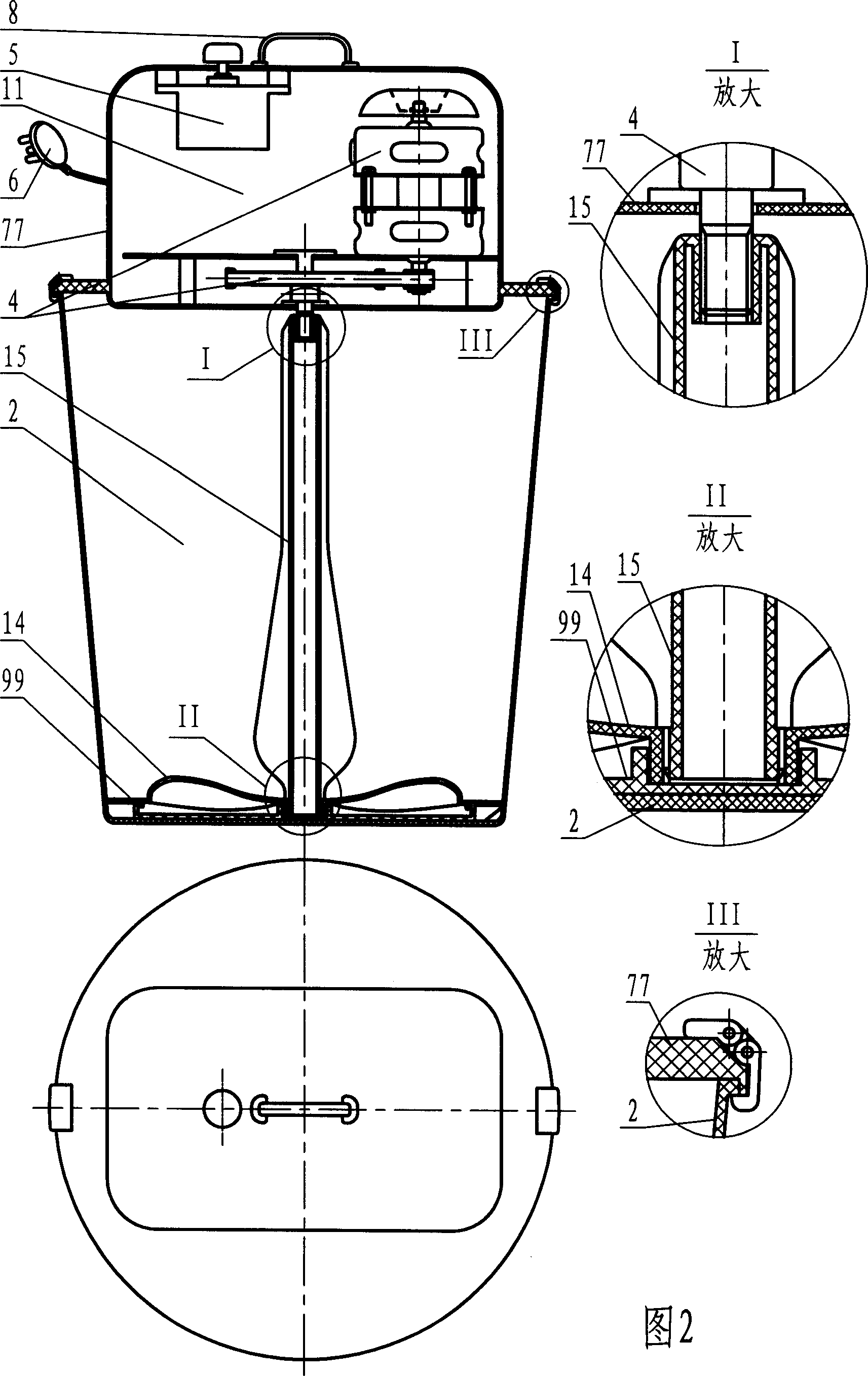

[0029] Fig. 2 illustrates the structure of the 2nd kind of portable electric washing machine 11 and its cooperation with the same nominal 22L, portable round plastic bucket 2. Its difference with the first embodiment is:

[0030] ——The end face of the housing 77 facing the water bucket 2 is in the shape of a round cap, which is buckled on the outer edge of the upper opening of the water bucket 2 . The nominal size of the inner diameter of the round cap is the same as the diameter of the outer edge of the upper opening of the bucket 2, and its size tolerance is processed so that it can be lifted manually without being too loose.

[0031] - The stirring wheel is a wave wheel 14 working at the bottom of the bucket 2, the center of the bottom is a circular shaft with a proper diameter and length; the center of the top is a spline hole with a proper diameter and depth. One piece is slightly smaller than the bottom diameter of bucket 2 so that the bottom of bucket 2 can be put into...

no. 3 Embodiment

[0037] Fig. 3 illustrates the structure of the third kind of portable electric washing machine 111 and its cooperation with two kinds of nominal specification portable round plastic buckets 22 common in the market. Its difference with the first embodiment is:

[0038] ——The end face of the housing 777 facing the water bucket 22 is clamped to the outer edge of the upper opening of the water bucket 22 through a bridge-shaped telescopic structure. The bridge-shaped telescopic structure includes: two arc clips 555a for clamping the outer edge of the upper opening of the bucket 22; two pairs of circular telescopic arms 555b connecting the arc clips 555a and the housing 777. The casing 777 is provided with a track for sliding along the moving direction of the telescopic arm 555b. When in use, adjust the telescopic arm 555b according to the size of the bucket 22 used. For a water bucket with a nominal value of 22L, the arc clamp 555a is at the solid line position shown in the figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com