Planetary transmission mechanism

A motion mechanism, planetary gear technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problems of small stroke and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

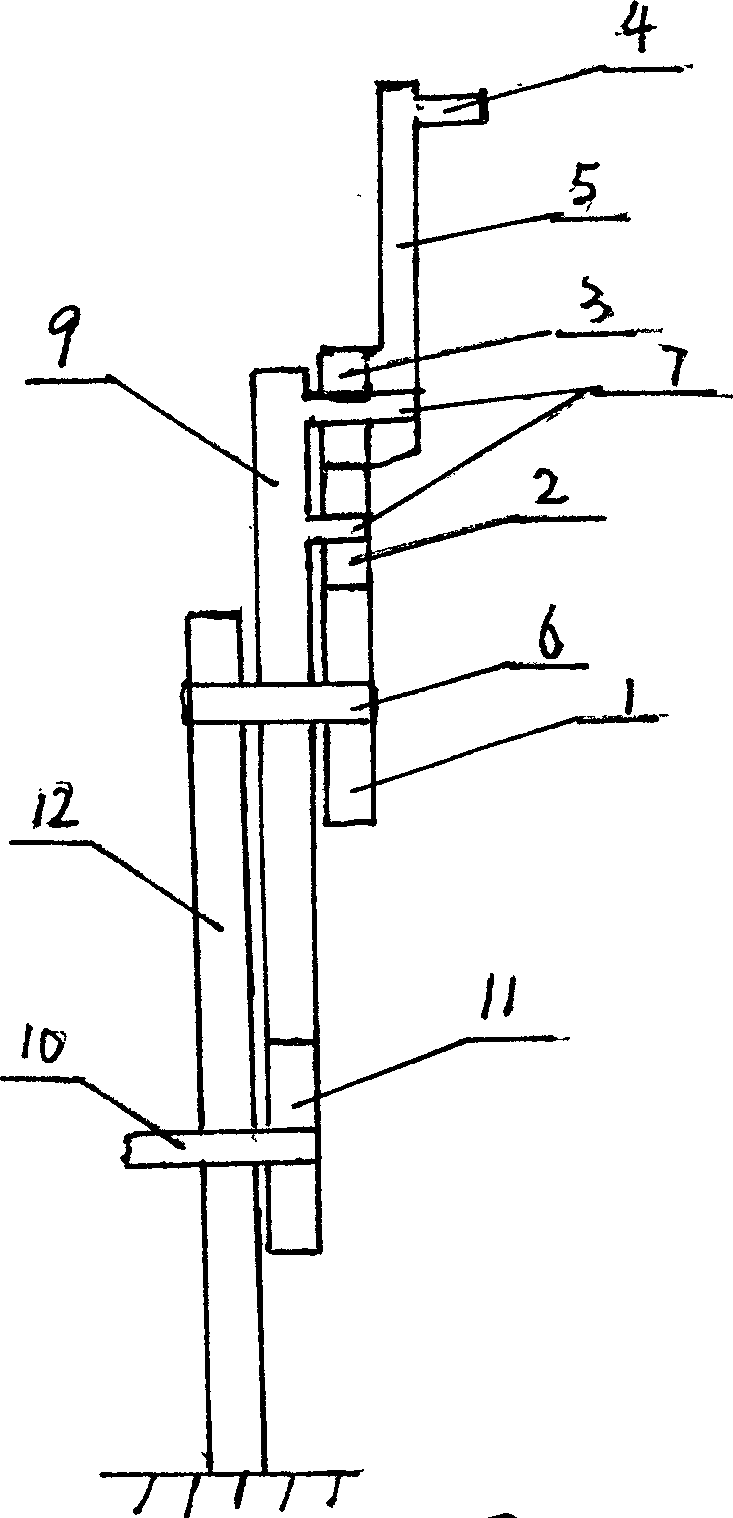

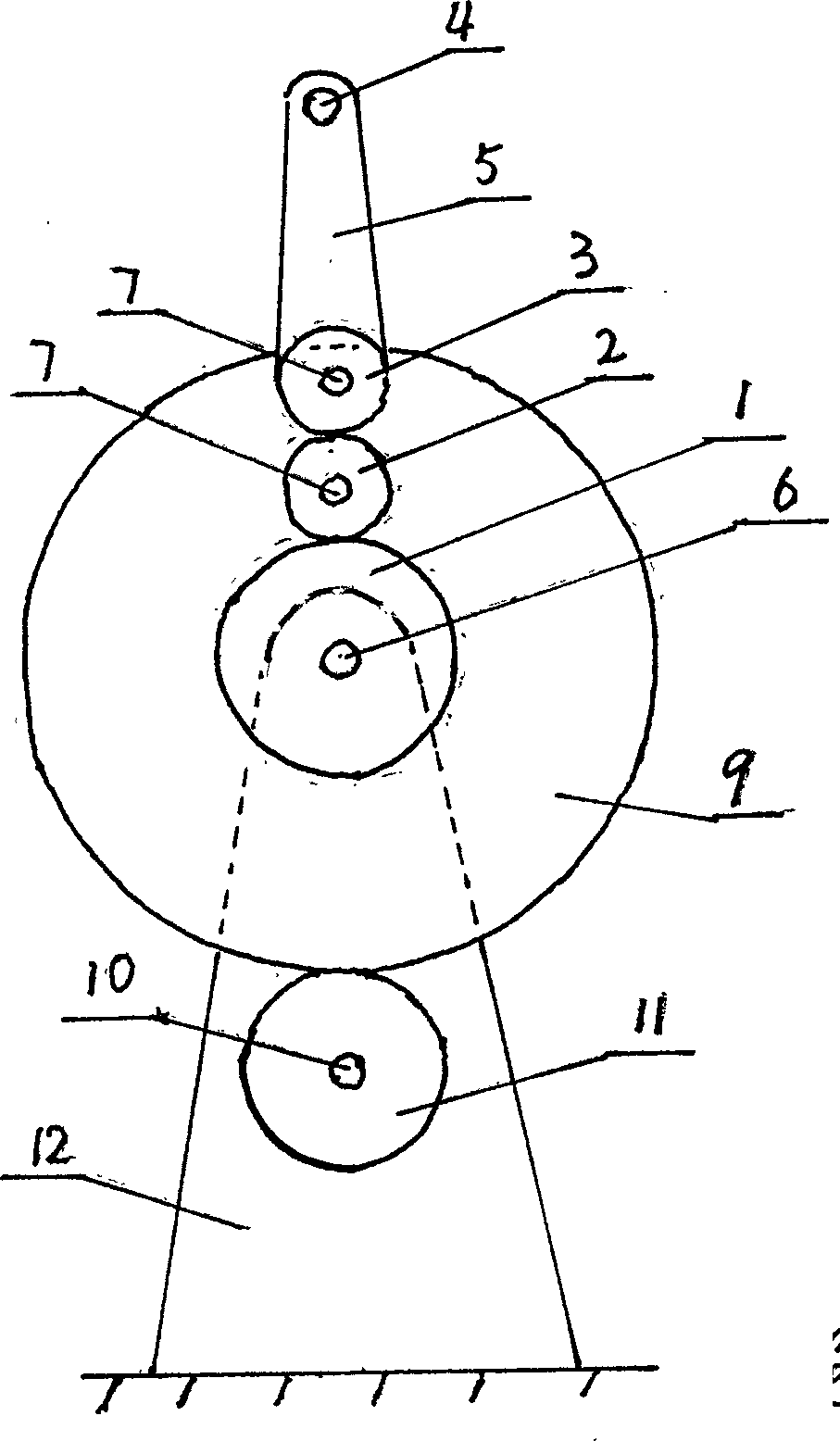

[0019] Please refer to figure 1 , figure 2 , the crank wheel (9) is coaxial (6) with the sun gear (1), the wheel (1) is fixed on the shaft (6), the shaft (6) is fixed on the bracket (12), the wheel (2) and the wheel ( 3) the axle (7) is fixed on the crank arm wheel (9), the wheel (2) is meshed with the wheel (1) and the wheel (3) respectively, the cantilever (5) is fixed on the wheel (3), and the satellite shaft (4 ) is fixed on the cantilever (5), and the diameter of the wheel (3) is 1 / 2 of the wheel (1), and its rotation is referring to the introduction of the front association mode.

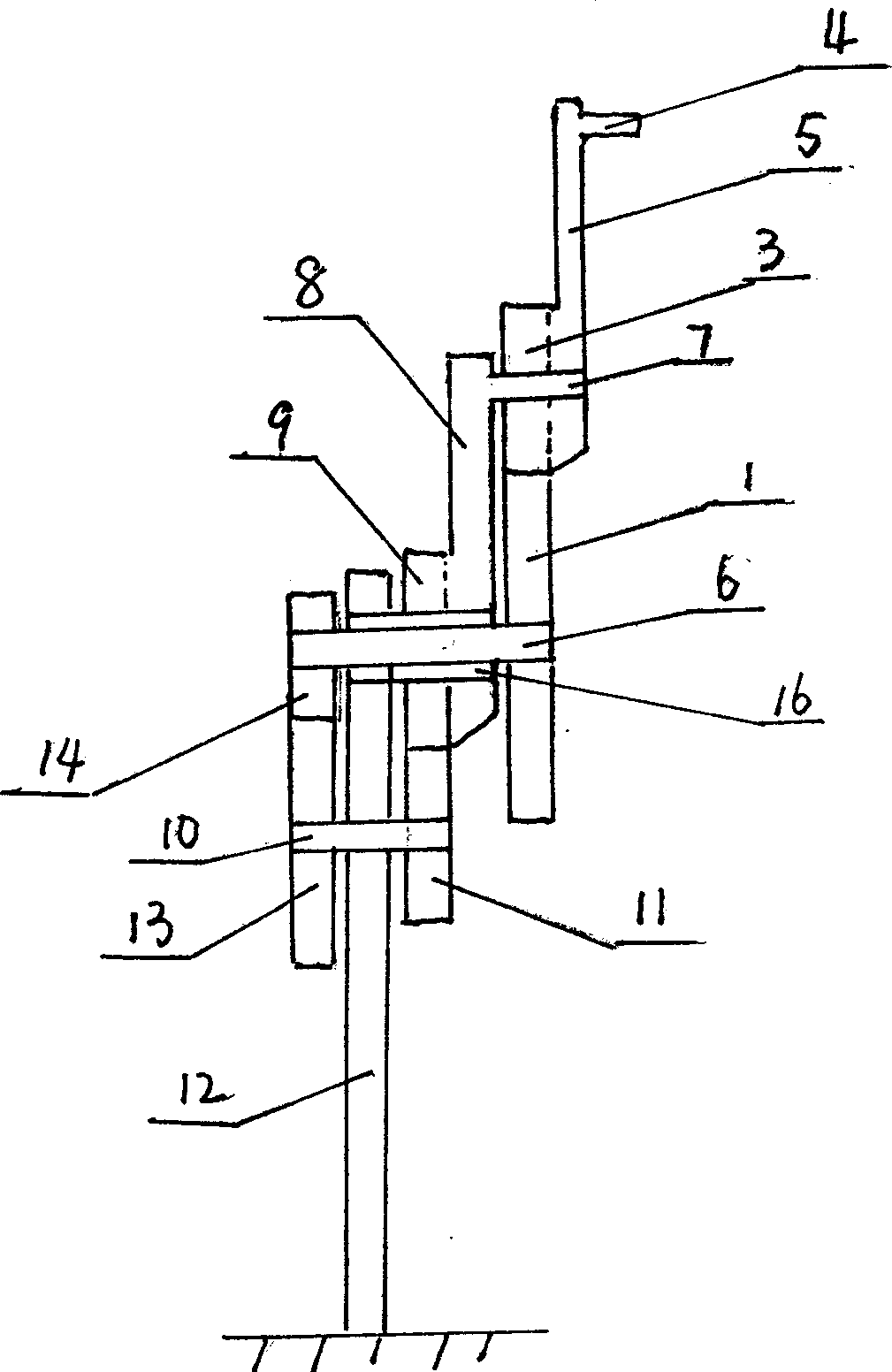

[0020] image 3 , Figure 4 Among them, the crank arm (8) and its connected crank arm wheel (9) take the fixed axle sleeve (16) as the axis, the main auxiliary wheel (14) and the sun gear (1) are fixed on the same shaft (6), and the wheel ( 3) mesh with wheel (1), wheel (11) mesh with wheel (9), wheel (13) mesh with wheel (14), wheel (11) and wheel (13) are fixed on the same axle (10).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com