Automotive air suspension shock-absorber

A shock absorber and gas technology, which is applied in the field of automobile suspension configuration, can solve problems such as poor gas sealing ability and poor single-cylinder work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

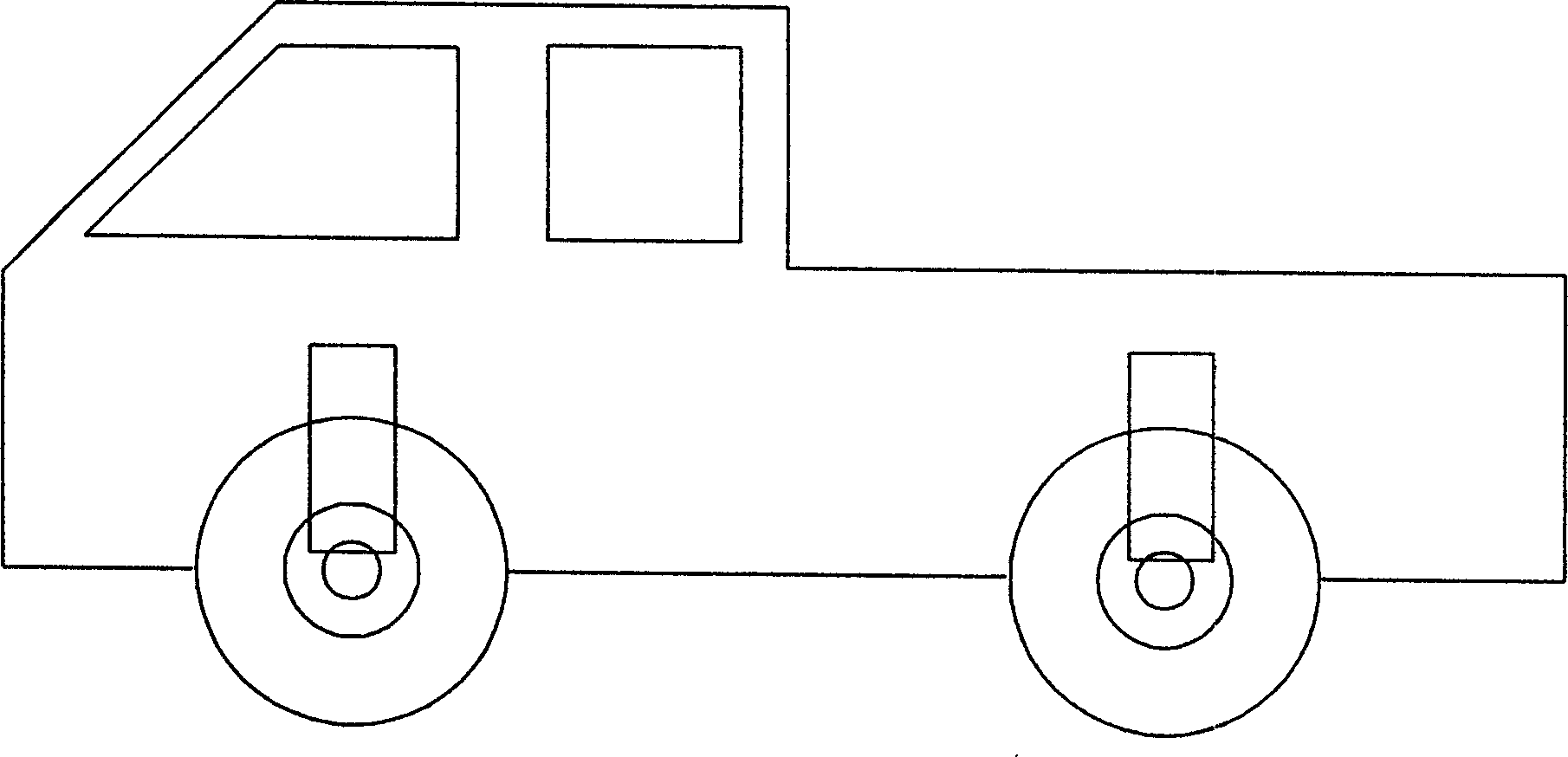

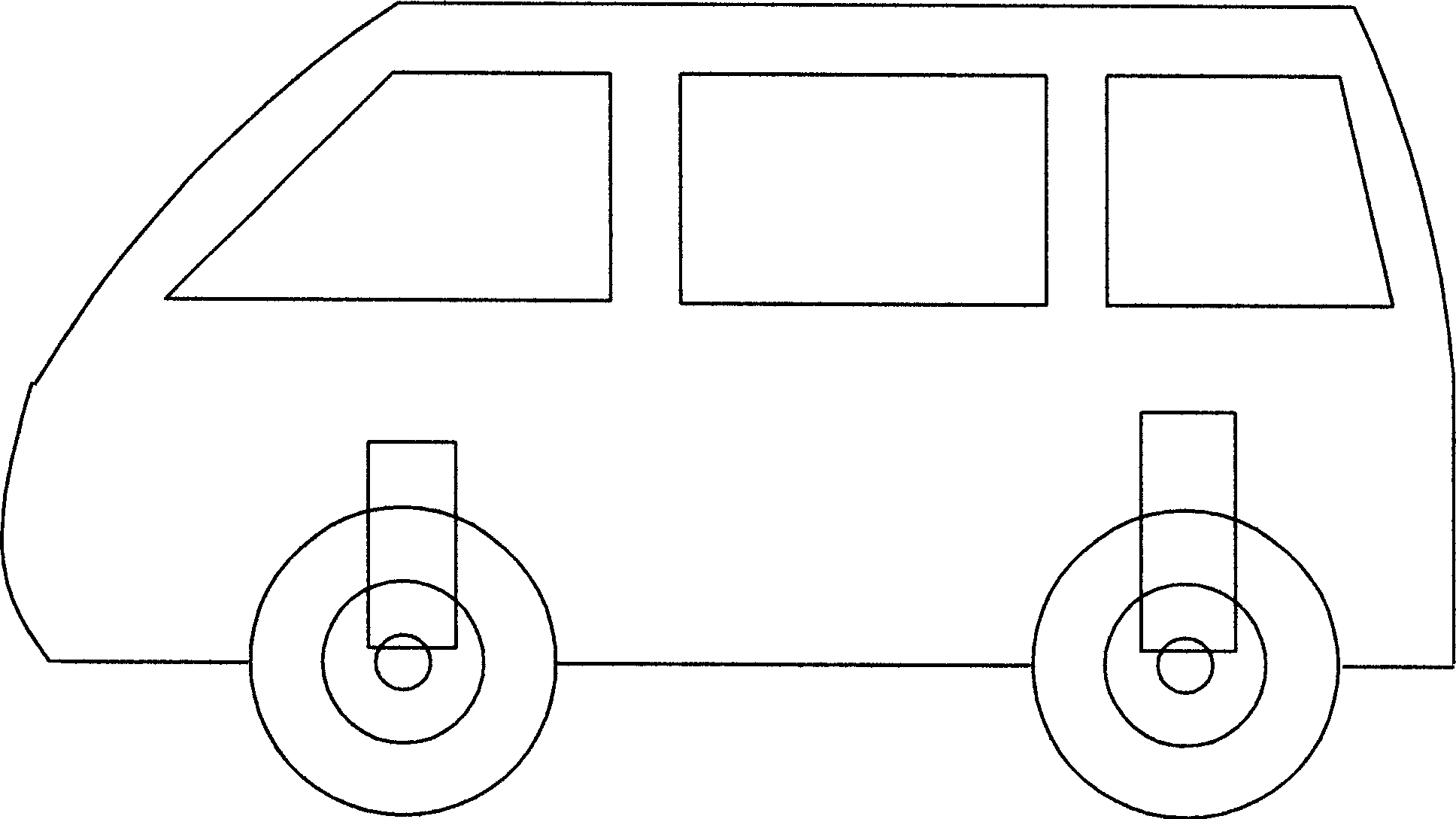

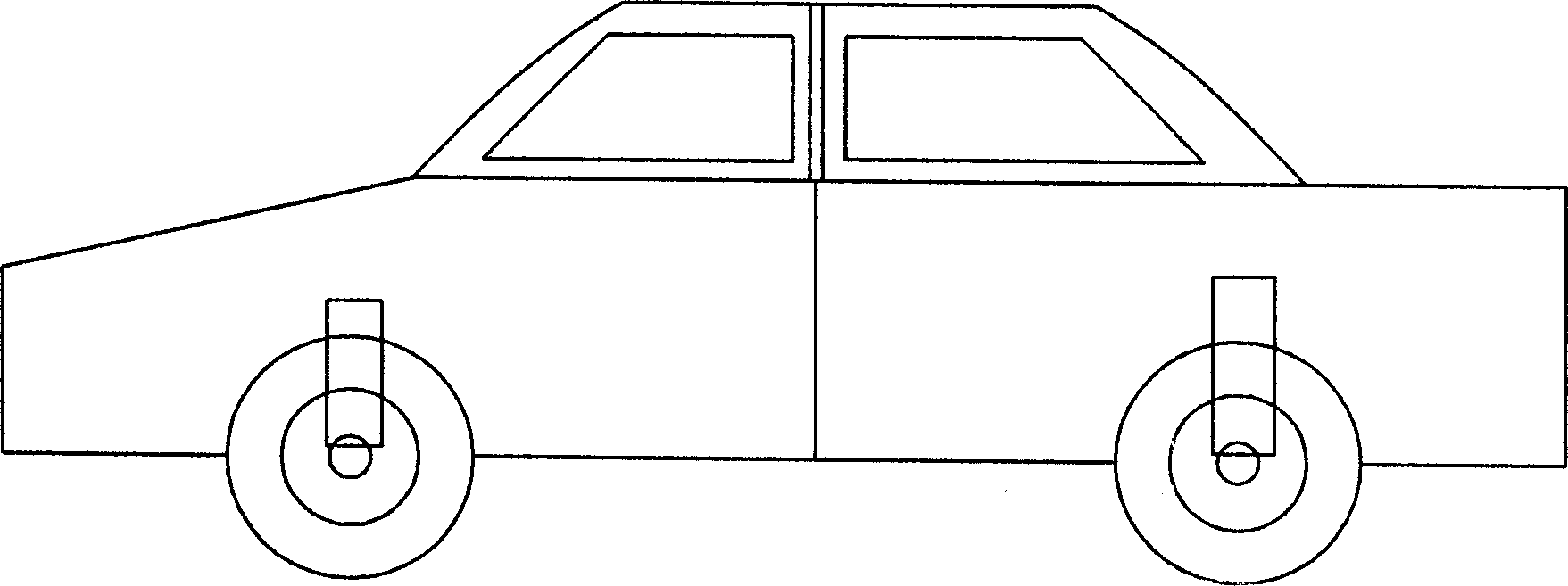

[0009] Embodiment: the main cylinder is connected with the axle, the main cylinder (1) and the main airbag (2) form the main airbag cylinder, and the auxiliary cylinder (4) and the auxiliary airbag (5) form the auxiliary airbag cylinder.

[0010] The main airbag cylinder, auxiliary airbag cylinder, and damping cylinder (8) slide and work at the same time under the connection of the fixed coupling (3) and the chute (7). When sliding, oil is supplied by the oil box (6). The top of the damping cylinder (8) has an air outlet valve (9) to link to each other with the car body.

[0011] This structure mainly uses the elasticity generated by the compressibility of the gas to complete the elasticity required by the suspension and the instantaneous resistance generated by the airless vacuum to complete the instantaneous resistance required for vibration reduction, isolate the vibration generated by the wheels during driving, and provide a sense of comfort. extremely strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com