Mechanical shaping drum

A technology of forming drums and machinery, applied in the field of rubber tire machinery, can solve the problems of the inherent quality influence of tire embryo forming, long waiting time, and the inability to guarantee uniform compaction quality, so as to improve the efficiency of compaction operation and improve compaction. The effect of quality, uniformity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

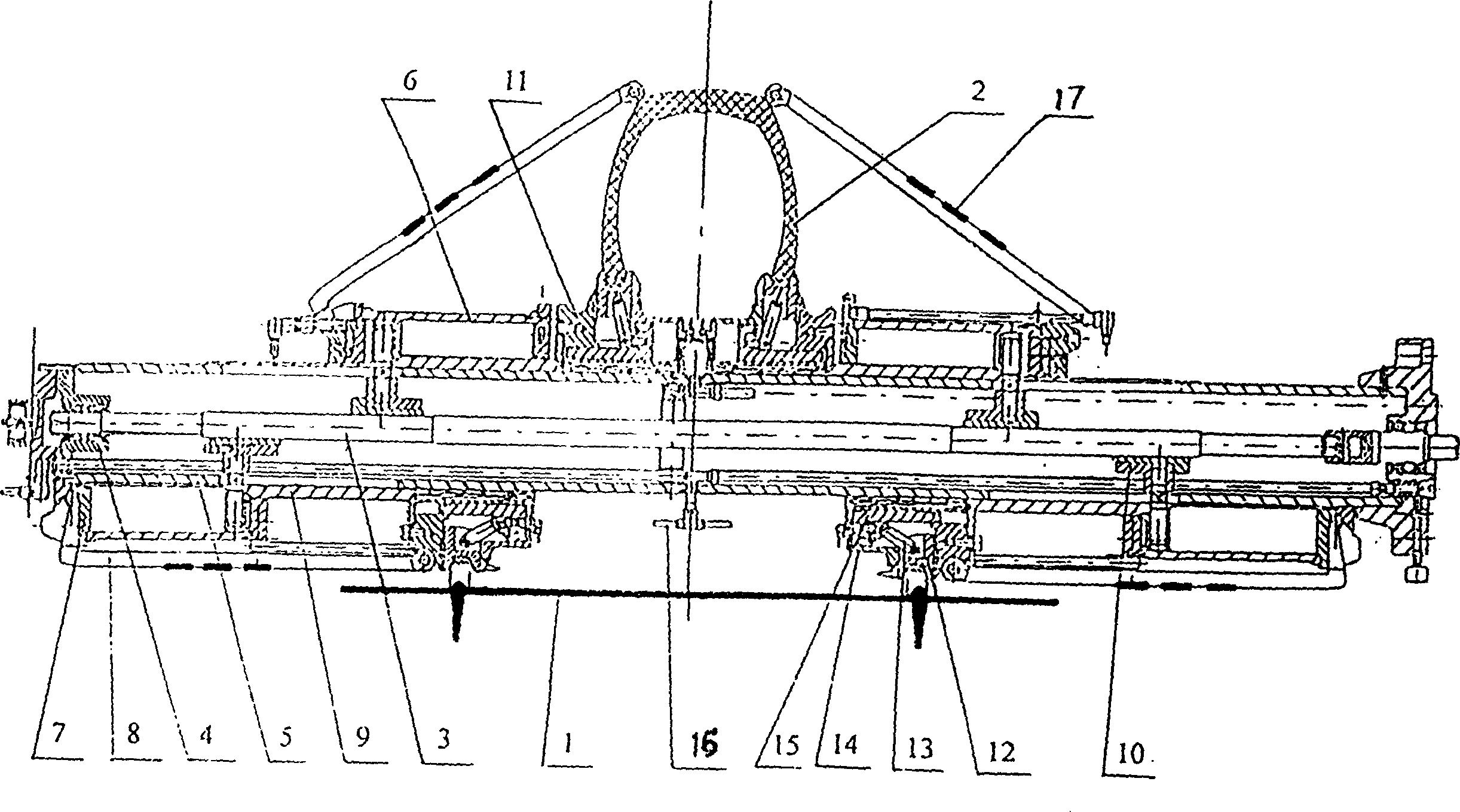

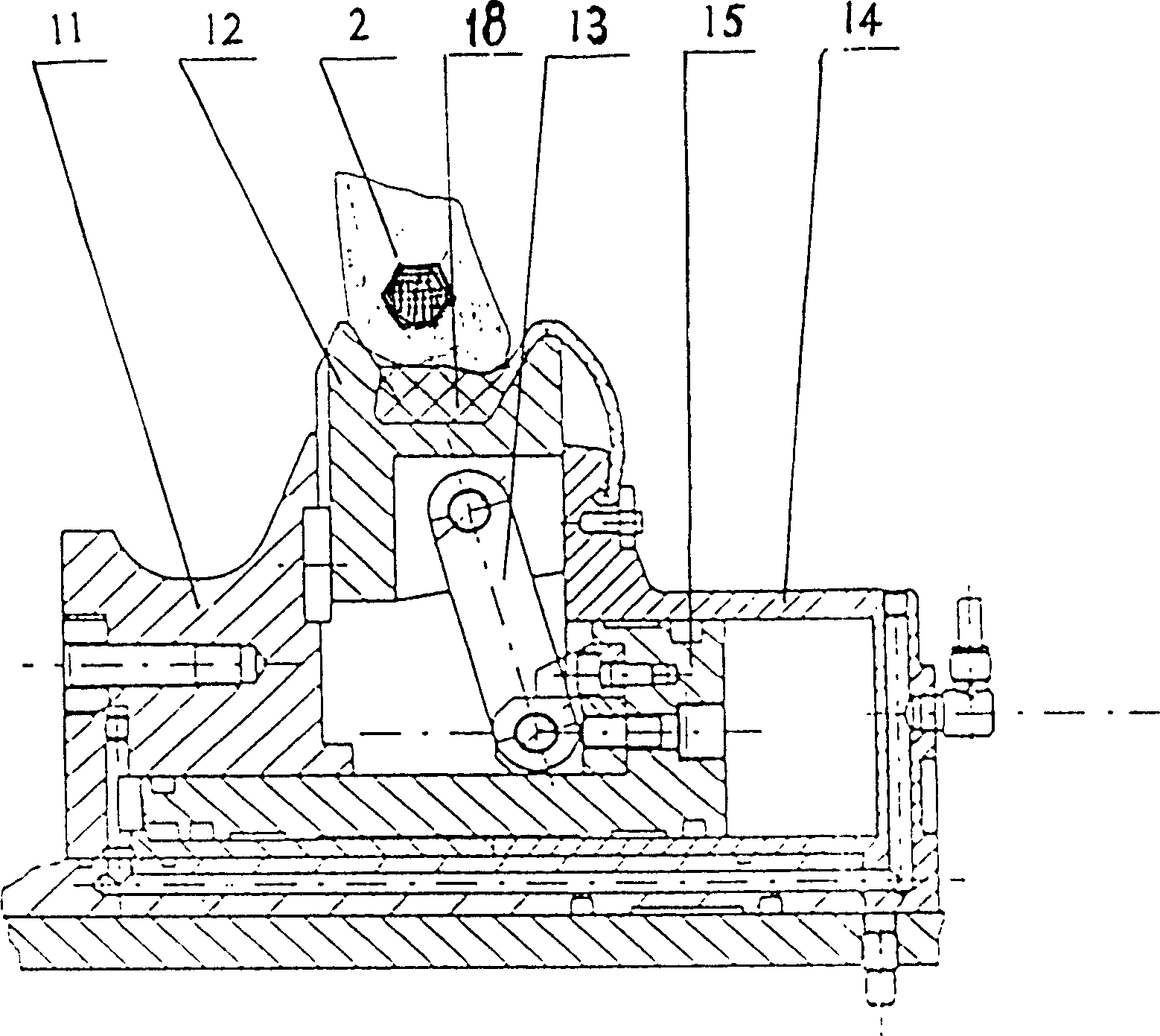

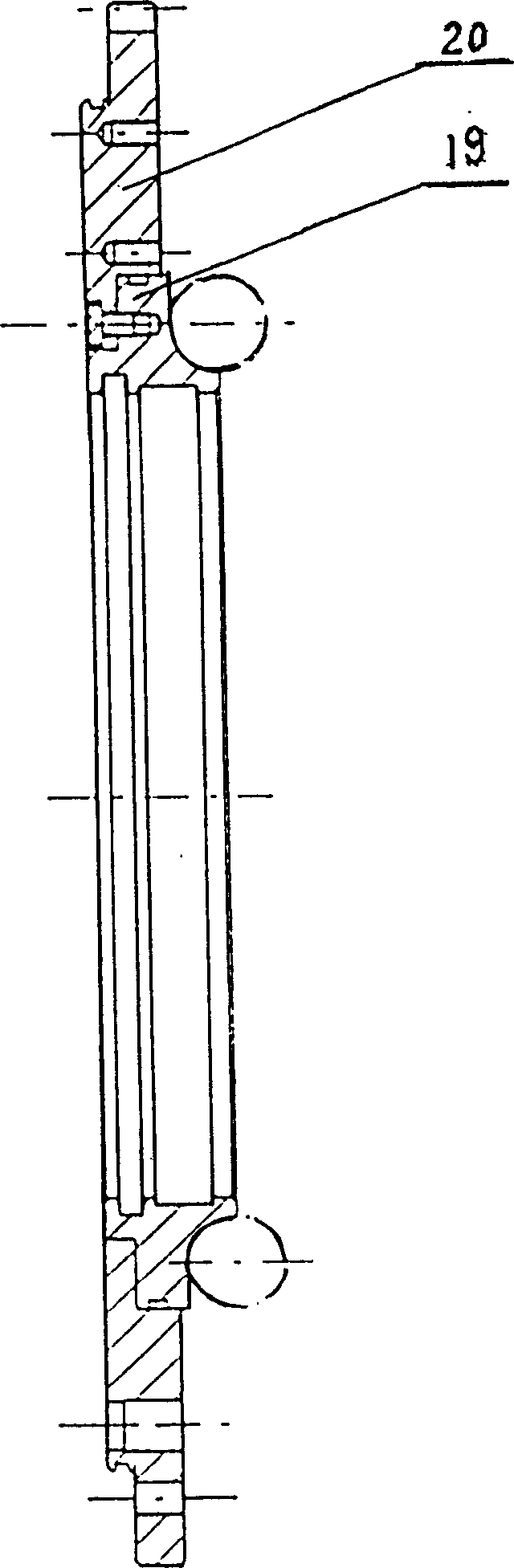

[0013] Embodiment: a kind of mechanical forming drum (see Figure 1-2 ), including transmission screw 3, bearing seat 4, main shaft 5, main shaft cylinder 6, main shaft bearing rear end cover 7, pressure roller arm 8, elastic rubber ring 17, main shaft piston 9, nut seat 10, ventilation pipe 16 and fastening The carcass mechanism is characterized in that there is a cylinder piston driving connecting rod device on the said fastening carcass mechanism, and the said cylinder piston driving connecting rod device is composed of a sector block cylinder block 14, a sector block cylinder block piston 15, a piston connection Rod 13, sector block 12, guide keyboard 11, gasket 18 are formed, and sector block cylinder body 14 is equipped with sector block cylinder body piston 15, and sector block cylinder body piston 15 has piston connecting rod 13, and piston connecting rod 13 and sector Block 12 is connected, and fan-shaped block 12 is installed in the guide keyboard 11 according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com