New process for fume desulfurization

A new process and flue gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of dust pollution, high operating costs, large investment in fixed facilities, etc., and achieve no dust pollution and low equipment investment. , The effect of avoiding salt mud pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

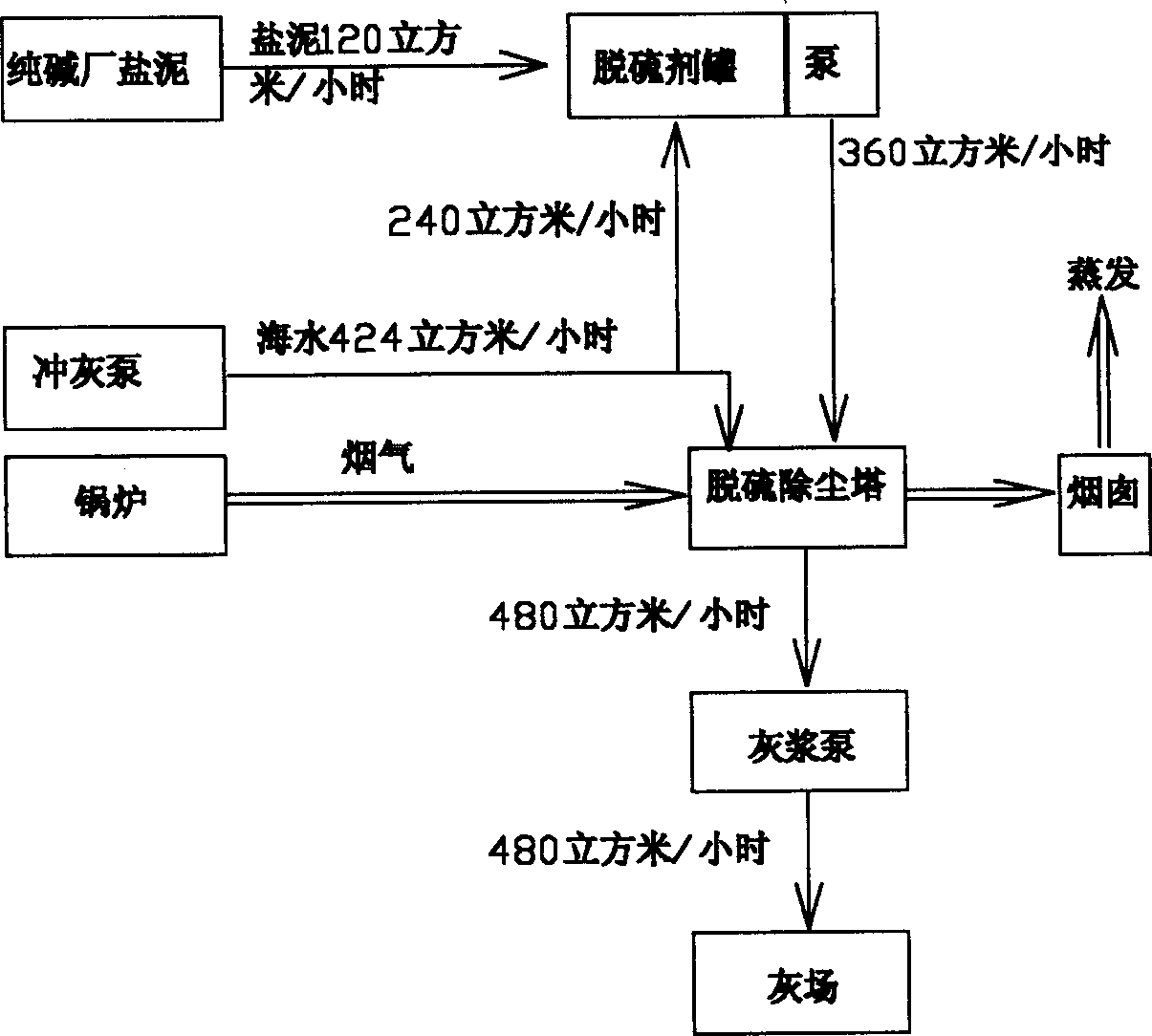

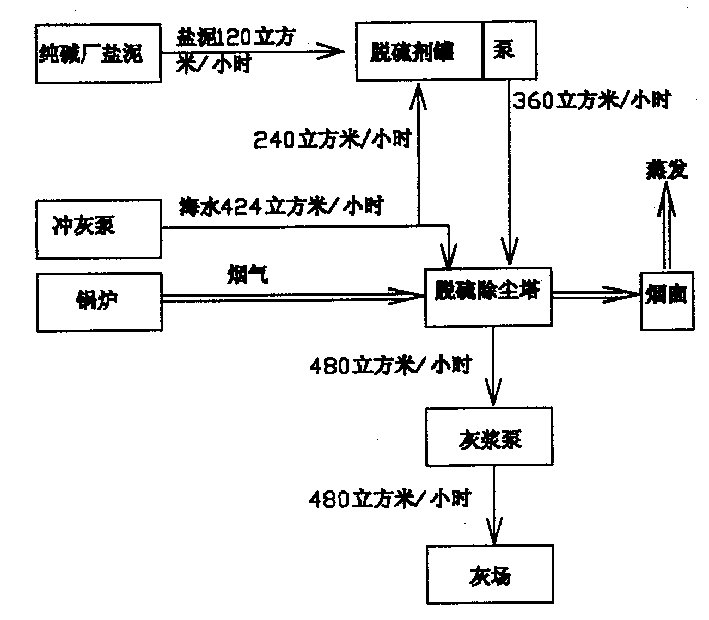

[0015] As shown in the accompanying drawings, the preferred embodiment of the present invention is implemented in the self-contained thermal power plant of the soda ash plant, because the soda ash plant is usually built on the seaside and has abundant seawater and salt mud resources. The desulfurization liquid is prepared by mixing the salt sludge produced by the soda ash factory with the seawater in a volume ratio of 1:2, and then the seawater and the desulfurization liquid are simultaneously pumped to the desulfurization tower in a volume ratio of 1:2. The flue gas in the desulfurization tower is inhaled for reaction, the liquid-gas ratio is controlled at about 1.5 liters / m3, and the reaction time is about 4 seconds. Finally, the reacted mortar water is directly pumped to the ash yard through a mortar pump.

[0016] The method firstly dilutes the salt mud with sea water, increases the fluidity of the salt mud, makes full use of the abundant sea water resources, and reduces t...

Embodiment 2

[0018] The desulfurization liquid is prepared by mixing the salt mud and seawater produced by the soda ash factory after producing soda ash in a volume ratio of 1:2.5, and then pumping the seawater and the desulfurization liquid into the desulfurization tower in a volume ratio of 1:1.5 at the same time. The flue gas in the desulfurization tower is inhaled for reaction, the liquid-gas ratio is controlled at about 1.0 liters / m3, and the reaction time is about 3 seconds. Finally, the reacted mortar water is directly pumped to the ash yard through a mortar pump.

Embodiment 3

[0020] The desulfurization liquid is made by mixing the salt mud and seawater produced by the soda ash factory after producing soda ash in a volume ratio of 1:1.5, and then pumping the seawater and the desulfurization liquid into the desulfurization tower in a volume ratio of 1:2.5 at the same time. The flue gas in the desulfurization tower is inhaled for reaction, the liquid-gas ratio is controlled to be about 1.3 liters / m3, and the reaction time is about 3 seconds. Finally, the reacted mortar water is directly pumped to the ash yard through a mortar pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com