Portable atomization injection fire extinguisher

A fire extinguisher, portable technology, applied in the field of small and portable fire extinguishing devices, can solve problems such as movement, inconvenient operation, low fire extinguishing efficiency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

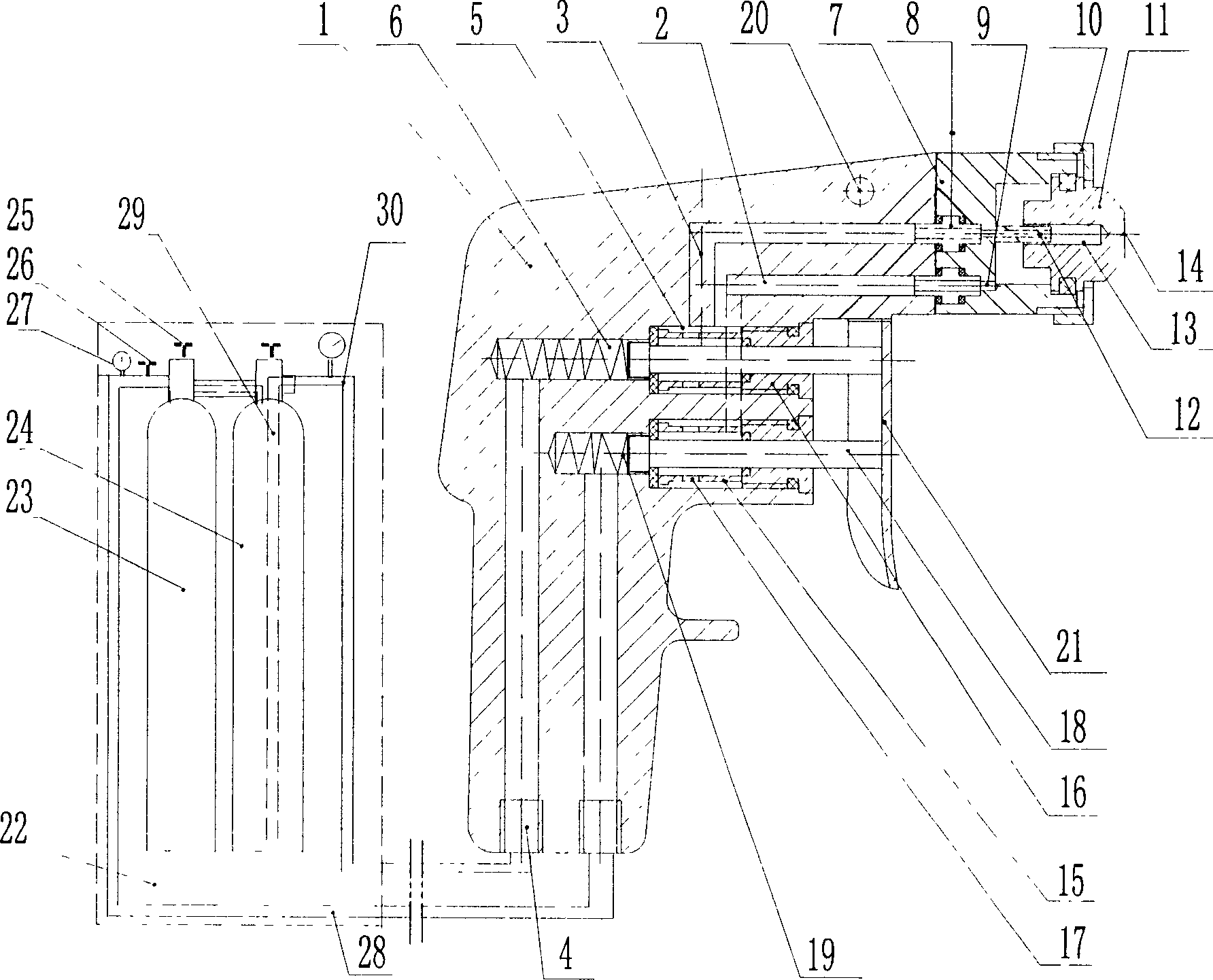

[0013] The gun body of the fire extinguishing gun is a rigid body with a thickness of 26mm; two outlet holes are opened in parallel up and down at the front end of the gun barrel, with a diameter of 3mm and a depth of about 40mm; The two spring holes and the switch hole are also juxtaposed up and down, the diameter of the spring hole is 5mm, and the diameter of the switch hole is 9mm; the compression nut is M10mm, the diameter of the ejector rod is 3mm, and the diameter of its end is 4mm; the diameter of the spring is 4.5mm, and the diameter of the wire is 0.8mm; the diameter of the connection hole 3mm, wherein, the fire extinguishing agent connection hole directly connects the switch hole with the outlet hole, and the pressure gas connection hole passes through a turning, avoiding the fire extinguishing agent switch hole, and connects the switch hole with the outlet hole; use the M24mm gland to connect the nozzle and the outlet hole. The nozzle seat is press-fitted, and the no...

Embodiment 2

[0015] The gun body of the fire extinguishing gun is a rigid body with a thickness of 30mm; two outlet holes are opened in parallel up and down at the front end of the gun barrel, with a diameter of 4mm and a depth of about 40mm; The two spring holes and the switch hole are also juxtaposed up and down, the diameter of the spring hole is 7mm, and the diameter of the switch hole is 10mm: the compression nut is M12mm, the diameter of the ejector rod is 3mm, and the diameter of its end is 6mm; the diameter of the spring is 6.5mm, the diameter of the wire is 1mm; the diameter of the connecting hole is 4mm , wherein, the fire extinguishing agent connection hole directly connects its switch hole with the outlet hole, and the pressure gas connection hole passes through a turning, avoids the fire extinguishing agent switch hole, and connects its switch hole with the outlet hole; use the M30mm gland to connect the nozzle and the nozzle The seat is press-fitted, the nozzle seat and the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com