Multifunctional thermodynamic simulated experiment machine

A thermal simulation and experimental machine technology, applied in teaching models, educational appliances, instruments, etc., to increase rigidity, improve test accuracy, and reduce frame deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

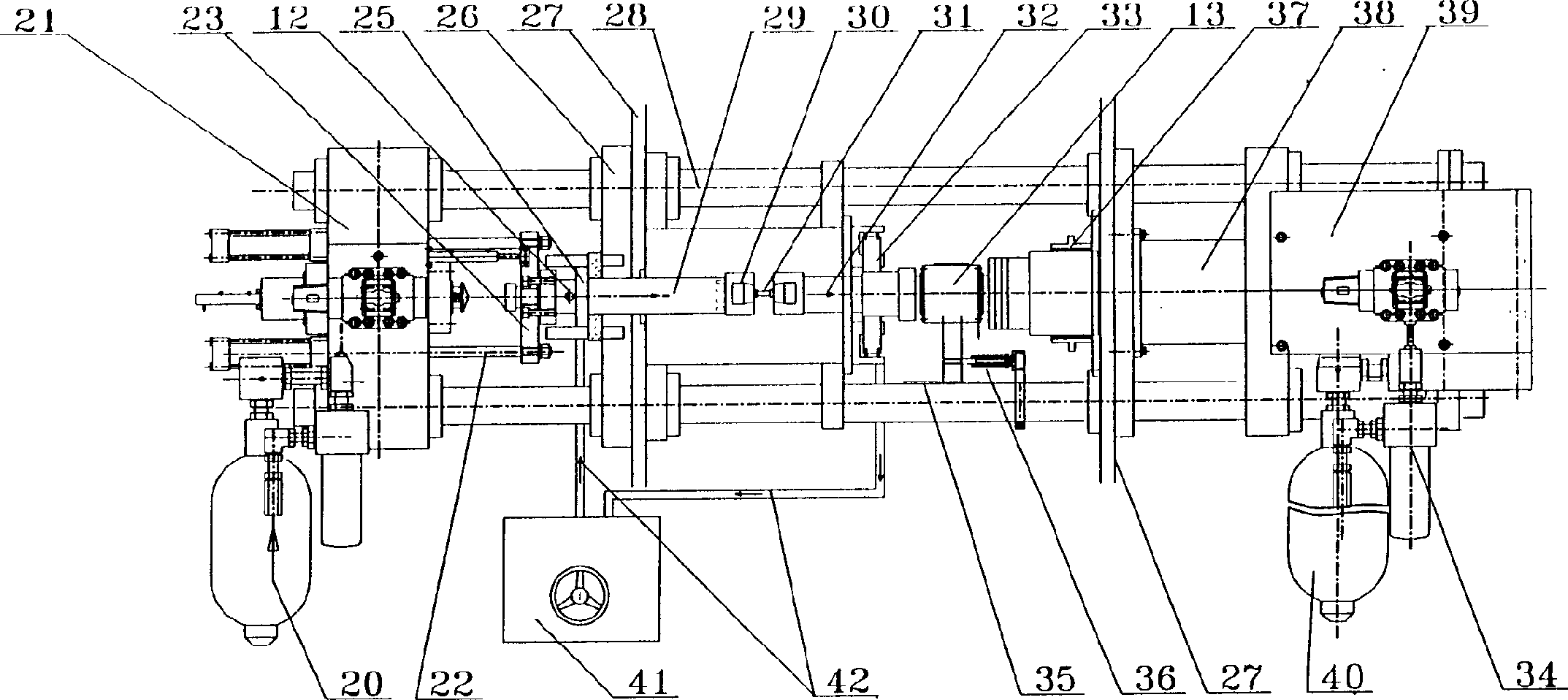

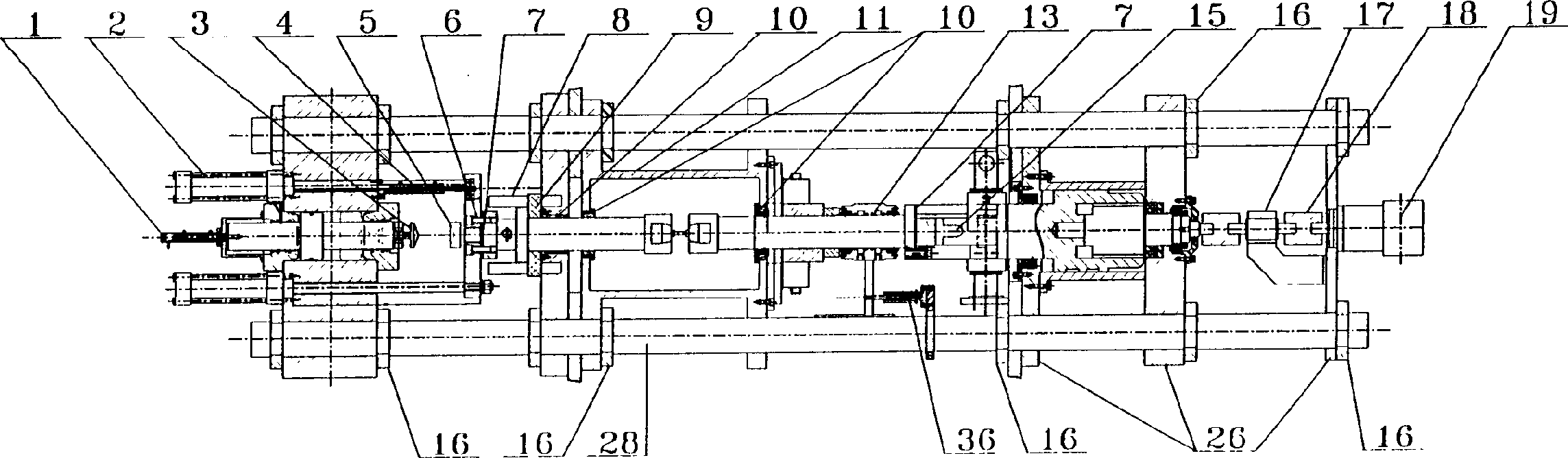

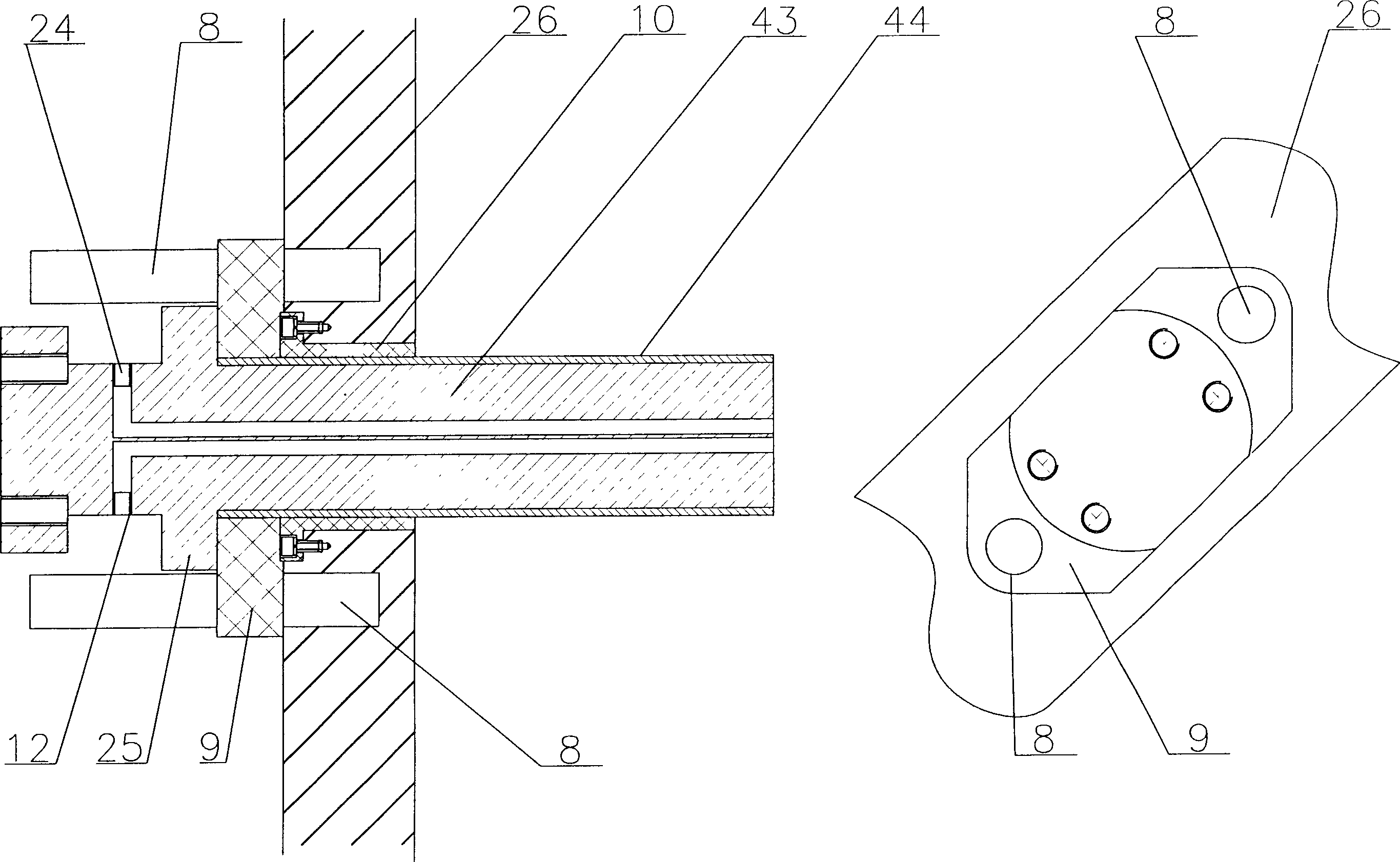

[0037] refer to figure 1 , figure 2 , The overall structure of the present invention is made up of parts such as two beams 28, main hydraulic cylinder 21, secondary hydraulic cylinder 39, left shaft 29, right shaft 32, operation box 11, test switching device 38, positioning beam 26 and support beam 27. The supporting beam 27 is supported on the ground by two sets of structural frames, and the structural frames including the beams 28 support the whole set of equipment. Crossbeam 28, four positioning beams 26, main hydraulic cylinder 21 and operation box 11 such as figure 1 The position shown in is tightly fixed into one body through a plurality of clamping rings 16 and is connected with the support structure frame through support beams 27, wherein two positioning beams 26, two cross beams 28 and the operation box 11 are directly connected with the support beams 27, in addition The two positioning beams 26 and the main hydraulic cylinder 21 are connected to the cross beam 28,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com