Two-stage speed variator device for converting electric tool

A technology for power tools and transmissions, applied in power tools, transmissions, gear transmissions, etc., can solve the problems of not having

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

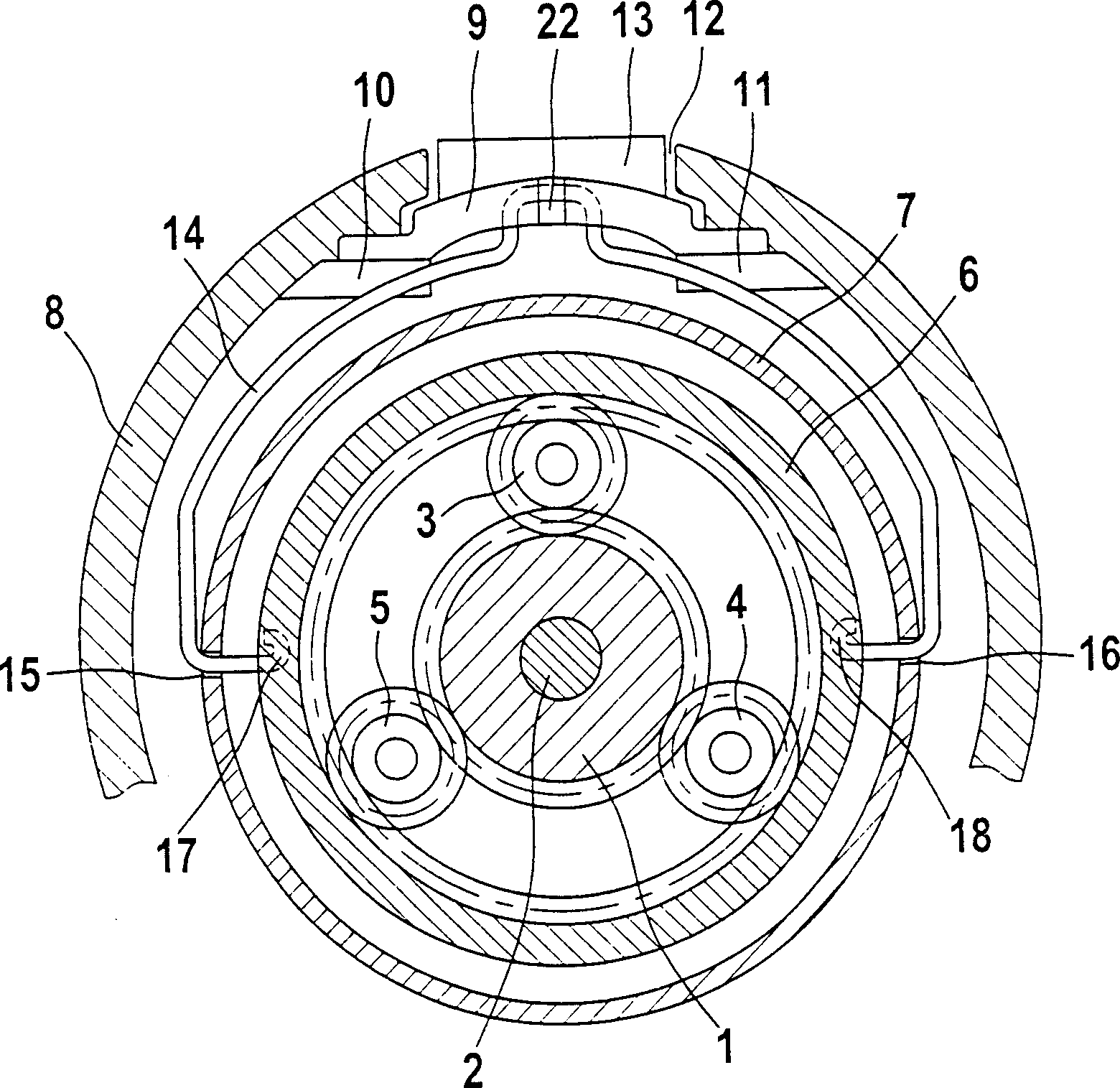

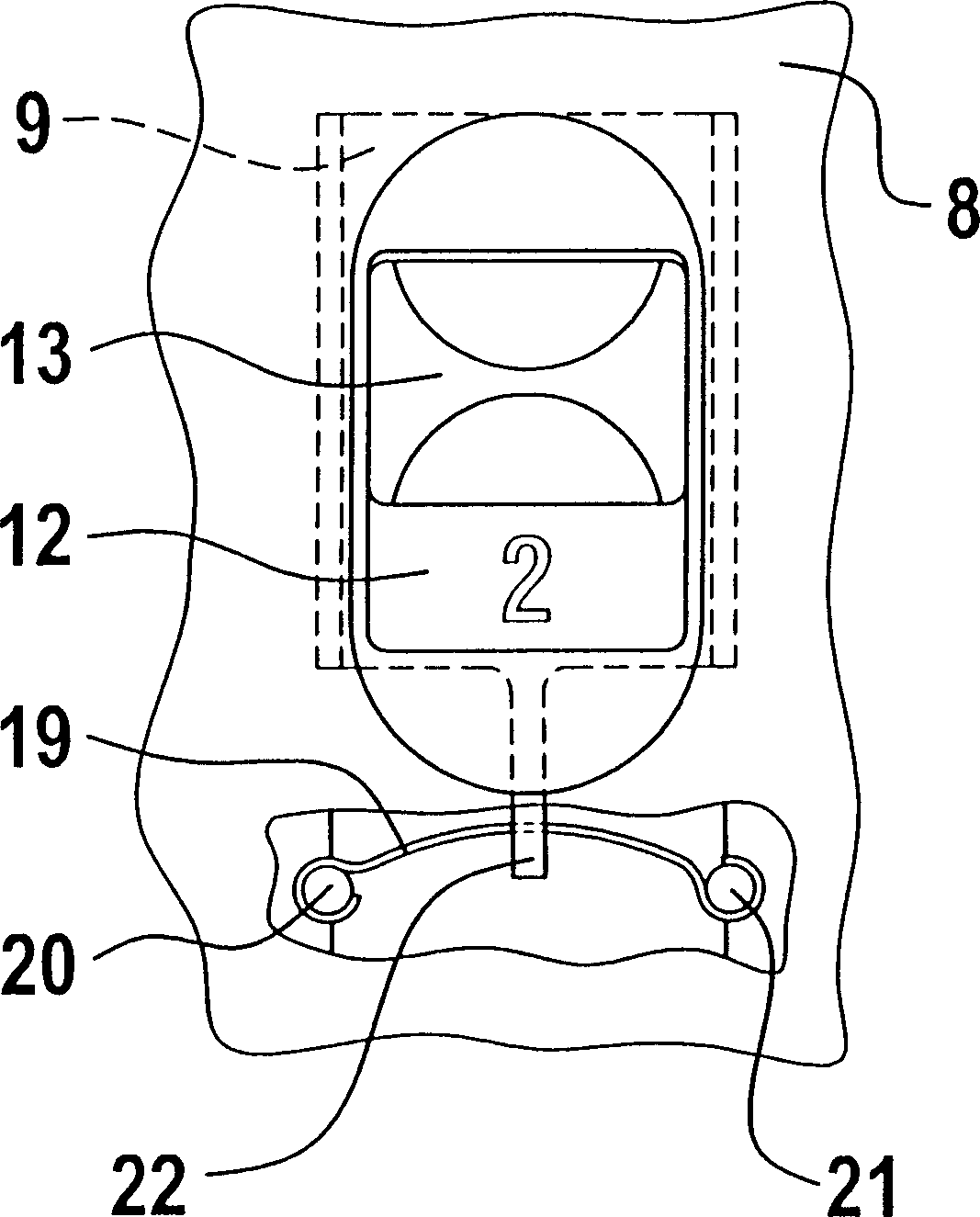

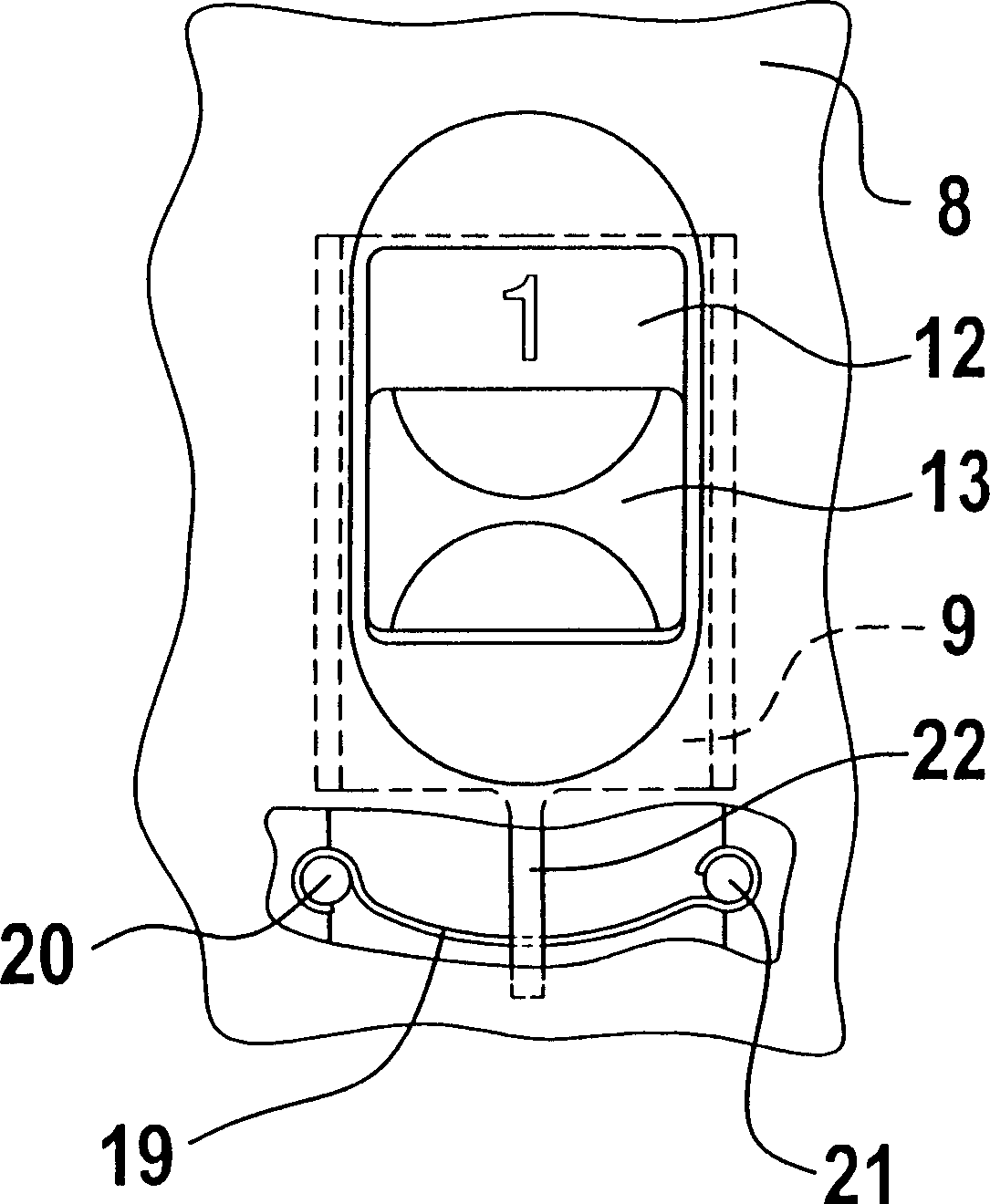

[0014] figure 1 A cross-sectional view of the planetary gear unit of a power tool such as a Bohrschrauber is shown in . This planetary gear unit comprises in a known manner - as can be seen from DE 39 04 085 A1 - a sun gear 1 which is non-rotatably connected to the drive shaft 2 of the electric motor, a plurality of planet gears meshing with the sun gear 1 3, 4 and 5, and an inner ring gear 6 surrounding the planetary gears and the sun gear, which meshes with the planetary gears 3, 4, 5. The entire transmission is enclosed in a transmission housing 7 . The ring gear 6 is supported movably in the axial direction of the drive shaft 2 . The axially displaceable ring gear 6 is used for shifting a planetary gear set designed here as two gears.

[0015] In the first position, the ring gear 6 meshes with a not-shown tooth portion on the transmission housing 7 so that it is fixed against rotation and the planet gears 3, 4 and 5 driven by the sun gear 1 are internally toothed. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com