Punching device for workpiece with flexibility

A piercing device and workpiece technology, applied in metal processing and other directions, can solve problems such as trouble, damage to the workpiece holder, damage to the sticking surface of the sheet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] best practice

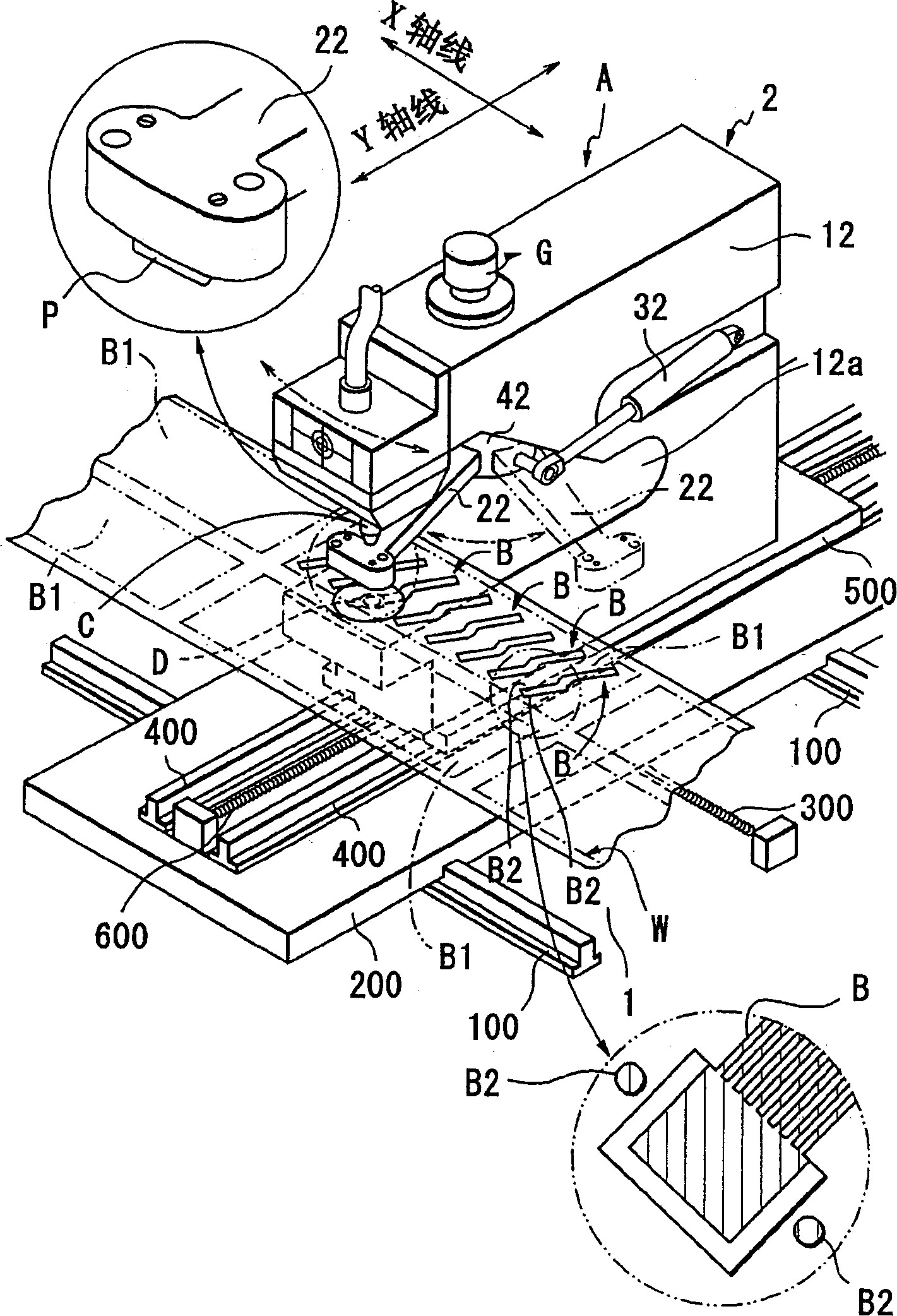

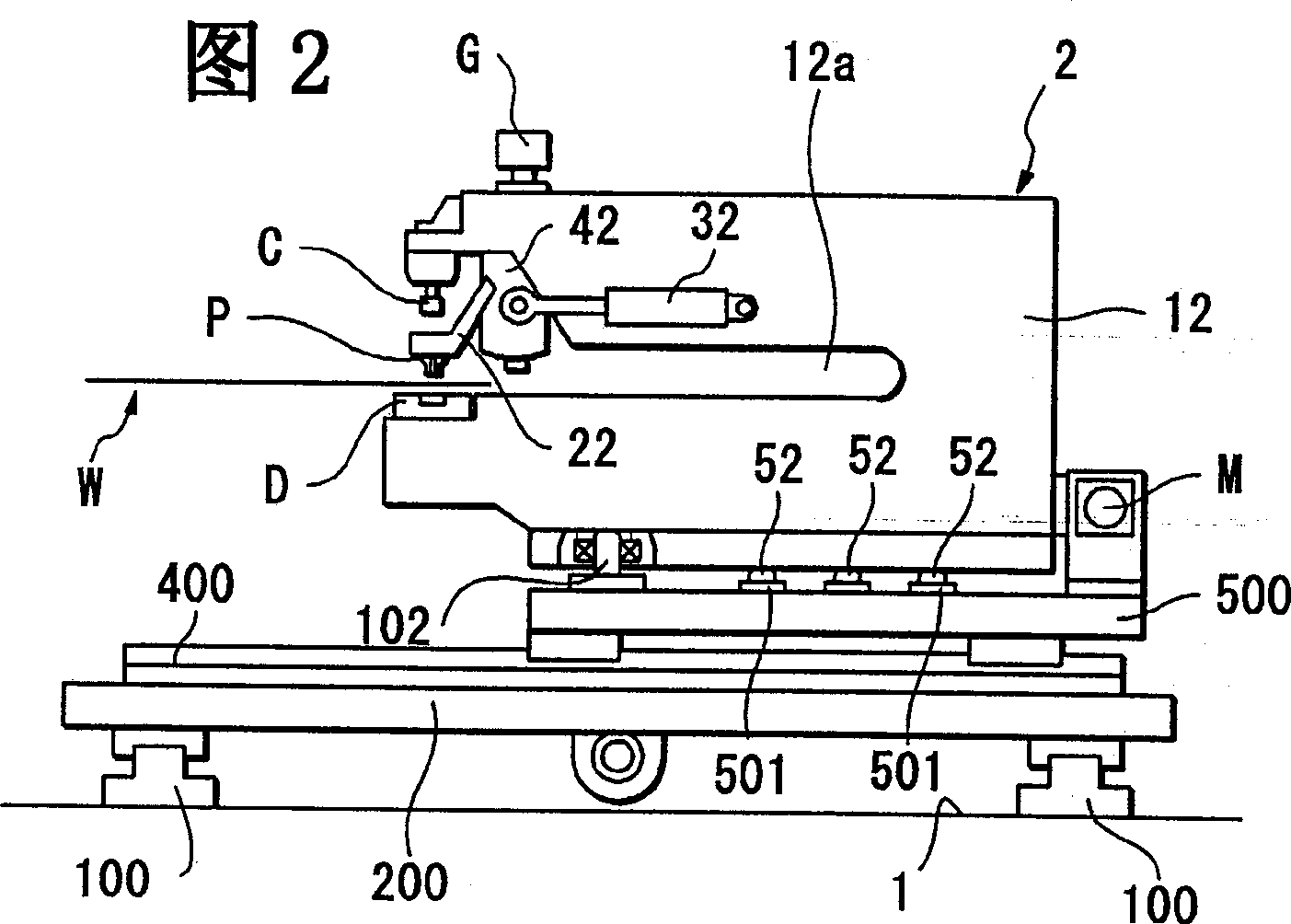

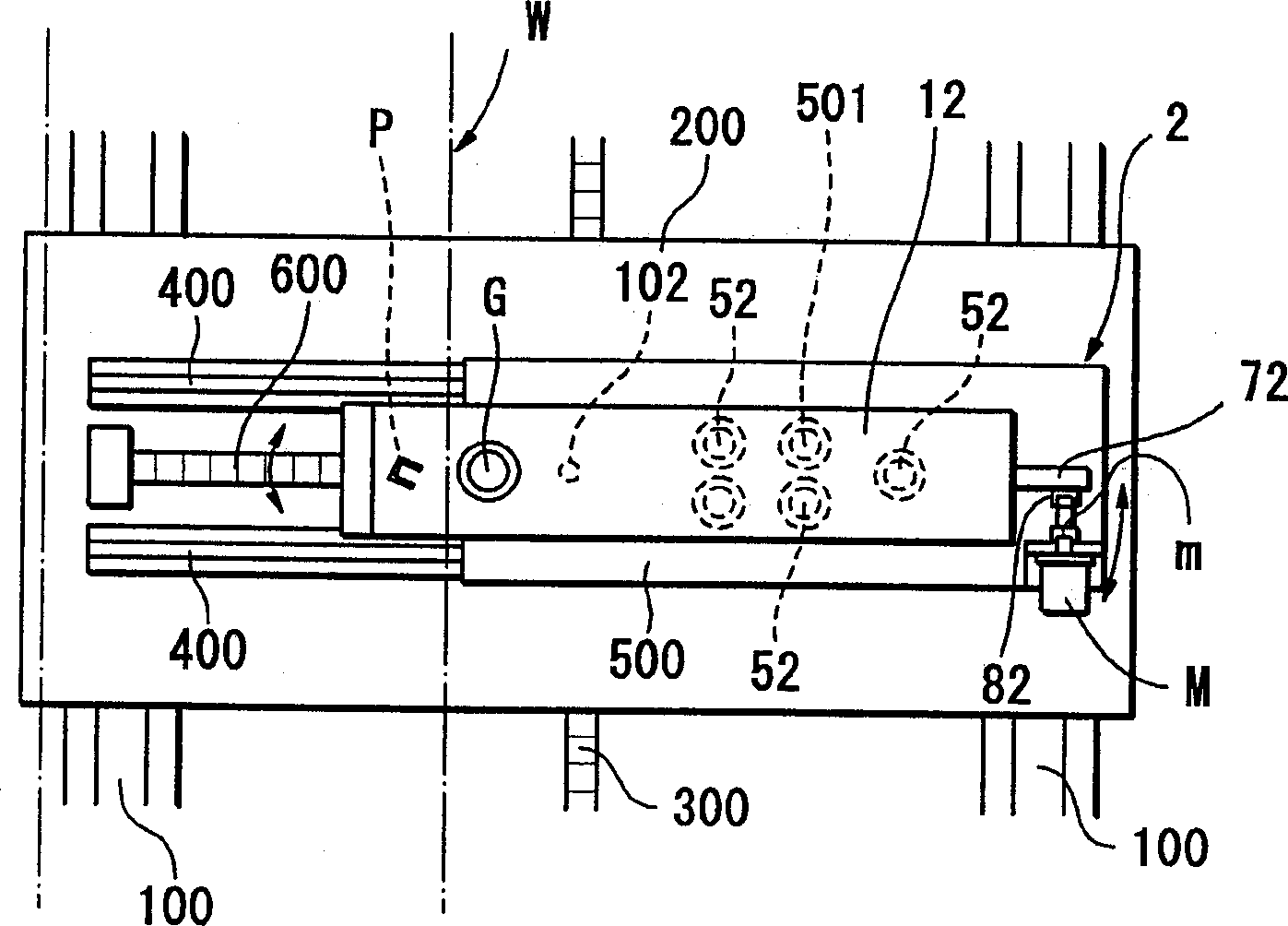

[0060] Next, an embodiment of the device for piercing a flexible workpiece according to the present invention will be described. Figure 1 to Figure 4 shows the first embodiment. Figure 5 and Figure 6 Shows the second embodiment. Figure 7 to Figure 11 shows the third embodiment. Fig. 12 shows a fourth embodiment. 13 to 15 show a fifth embodiment. 16 and 17 show a sixth embodiment. 18 and 19 show a seventh embodiment. 20 and 21 show an eighth embodiment. In each of the embodiments, a flexible printed wiring board is used as a work, and on the flexible printed wiring board, there are several reference points near the ends of a plurality of products formed in parallel. First, the first embodiment will be described, and symbol A is a perforating device.

[0061] Such as figure 1 As shown, the perforating device A is equipped with a drawing device (not shown), a winding device (not shown), and a strip-shaped belt wound between the drawing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com