Plastic light guide fiber end face processing method, apparatus, cutting blade and connecting method

A technology of optical fiber and processing device, which is applied in the coupling and optics of optical guides and optical waveguides, can solve problems such as inability to form, and achieve the effects of easy operation, simple end surface processing, and simple processing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

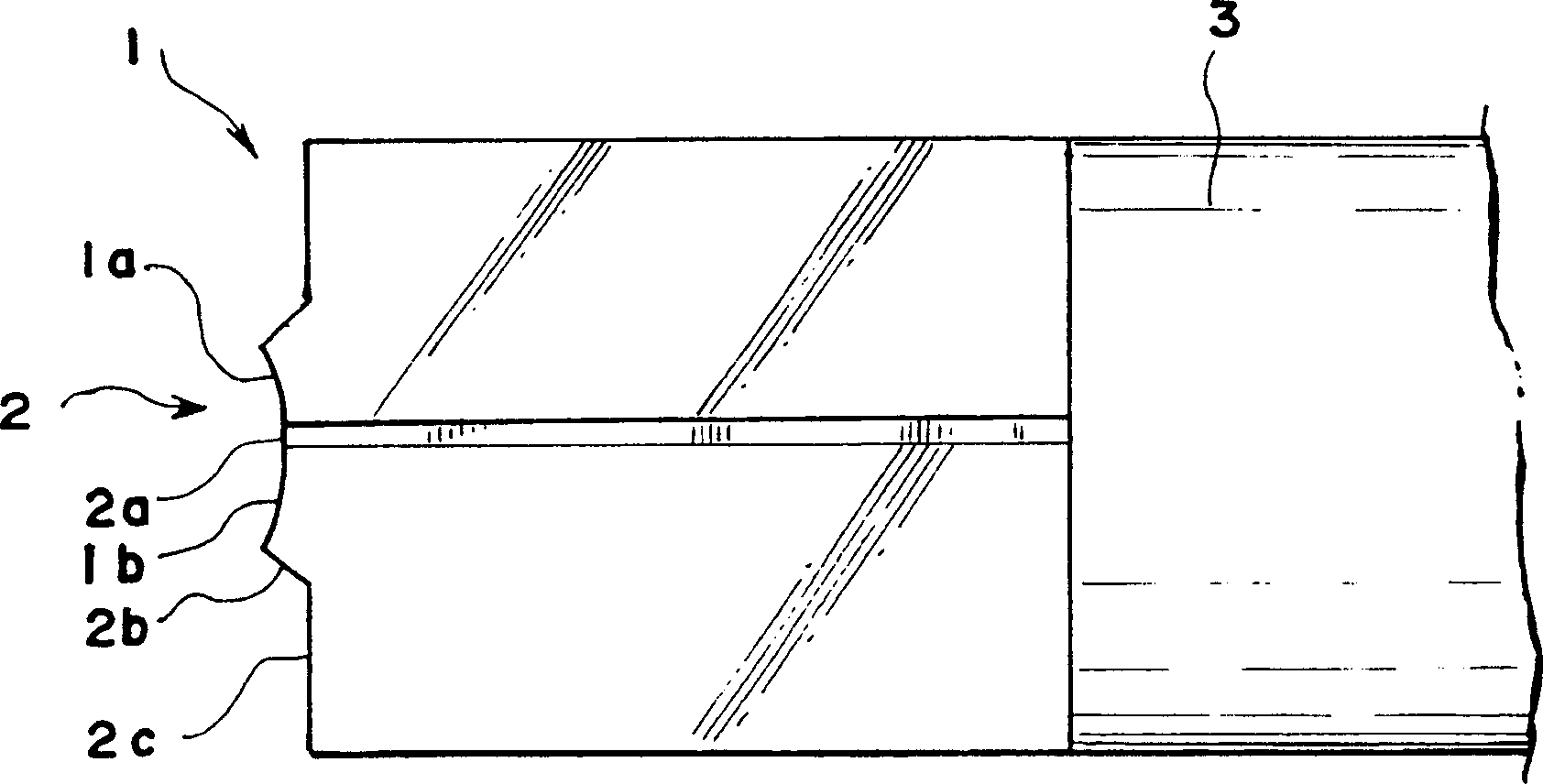

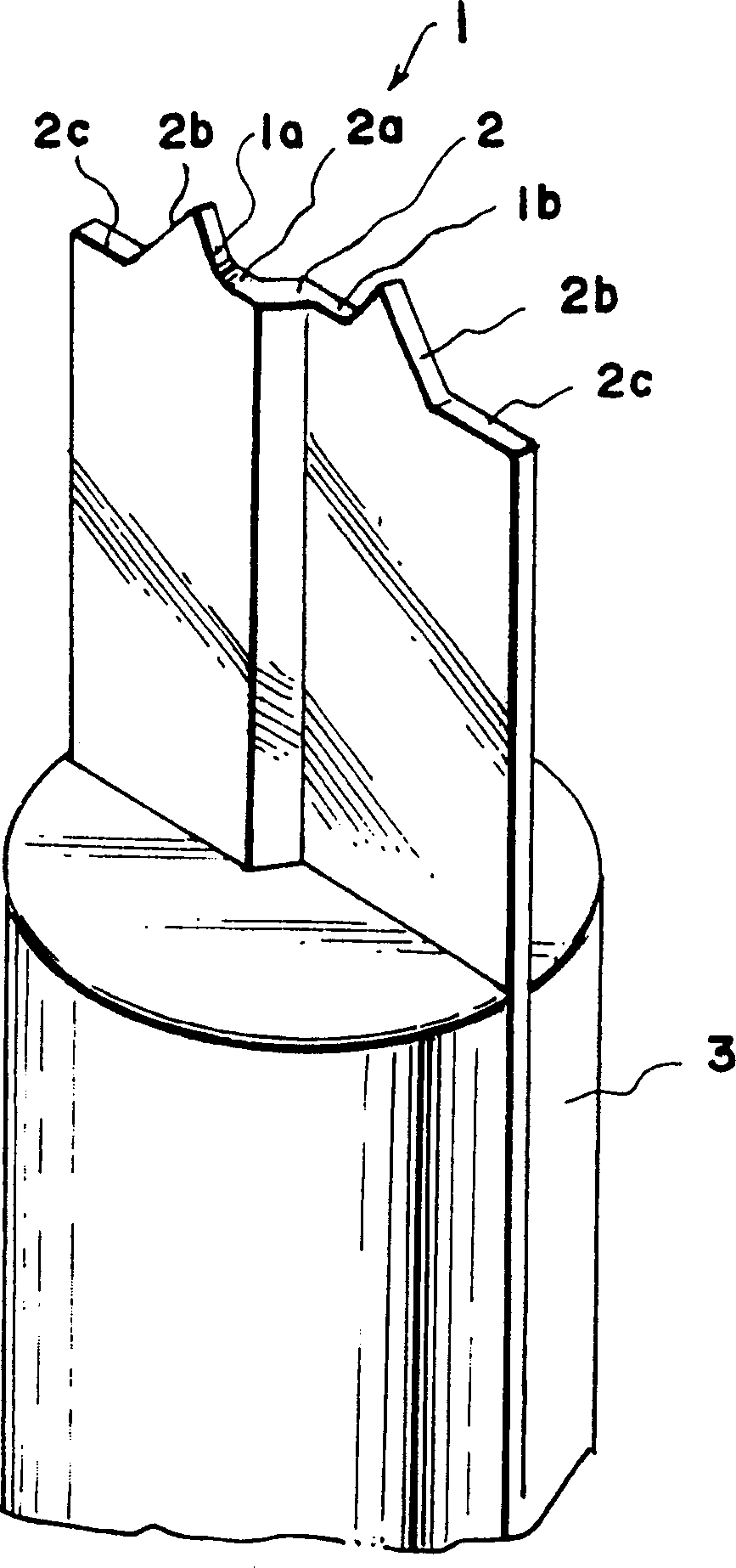

[0072] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. figure 1 It is an enlarged front view showing a cutting blade for processing an optical fiber end face according to an embodiment of the present invention. figure 2 It is an enlarged perspective view showing a main part of a cutting blade for processing an optical fiber end face according to an embodiment of the present invention.

[0073] In the above figure, the cutting edge 1 is provided at the tip of the shaft portion (cylindrical portion) 3. In this embodiment, the cutting edge 1 is formed into a convex semicircular shape by two cutting edges 1a, 1b. In detail, as figure 1 with figure 2 As shown, the tip 2 of the cutting blade 1 is formed in such a shape that the center is a semicircular concave portion 2a, an inclined portion 2b is continuously formed thereon, and is continuous with a vertical portion 2c.

[0074] In the above-mentioned embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com