Automatic continuous production of track optical biological reactor

A photobioreactor, runway-type technology, applied in the direction of photobioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc. Achieve high efficiency, energy saving, labor saving and other issues, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

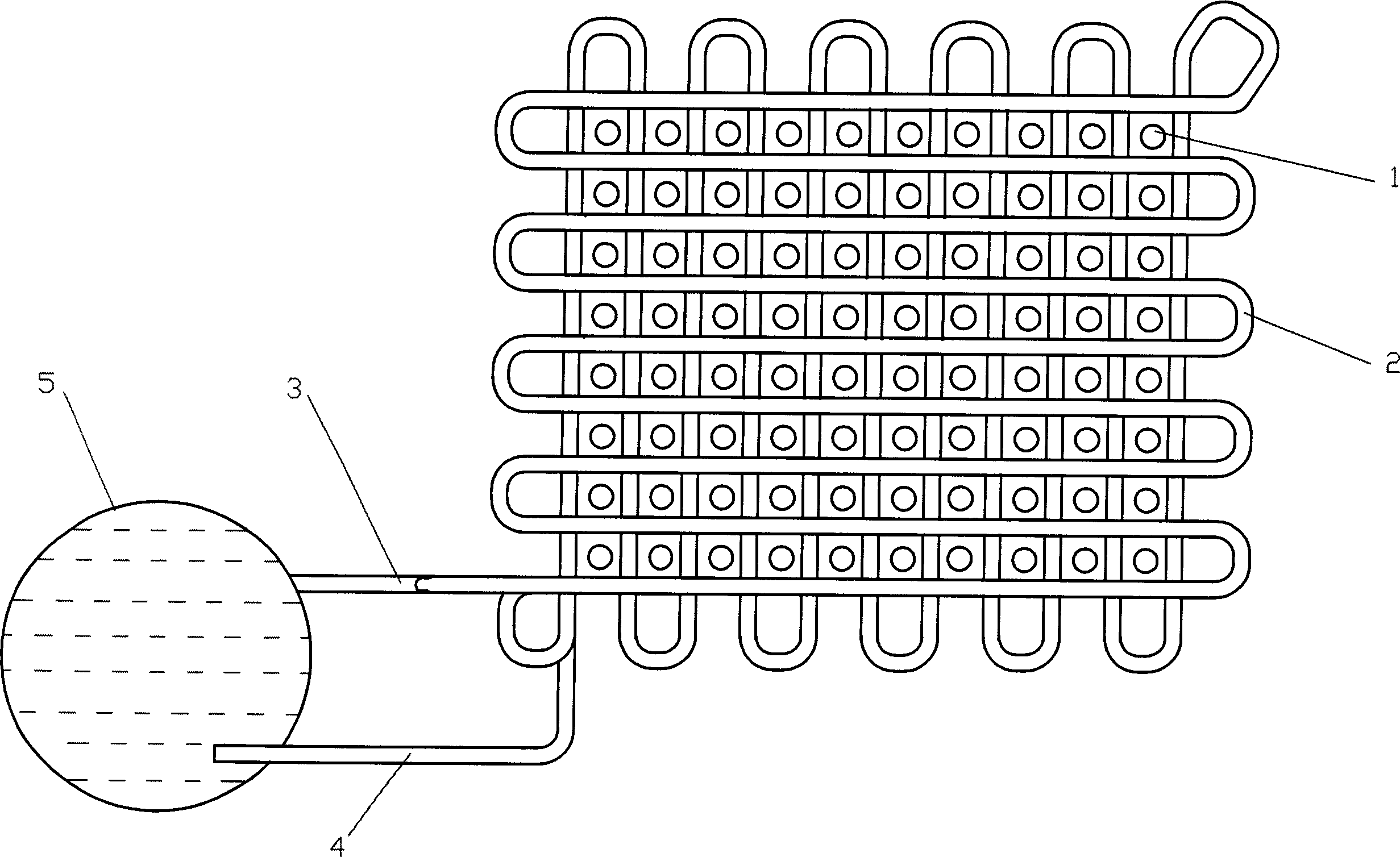

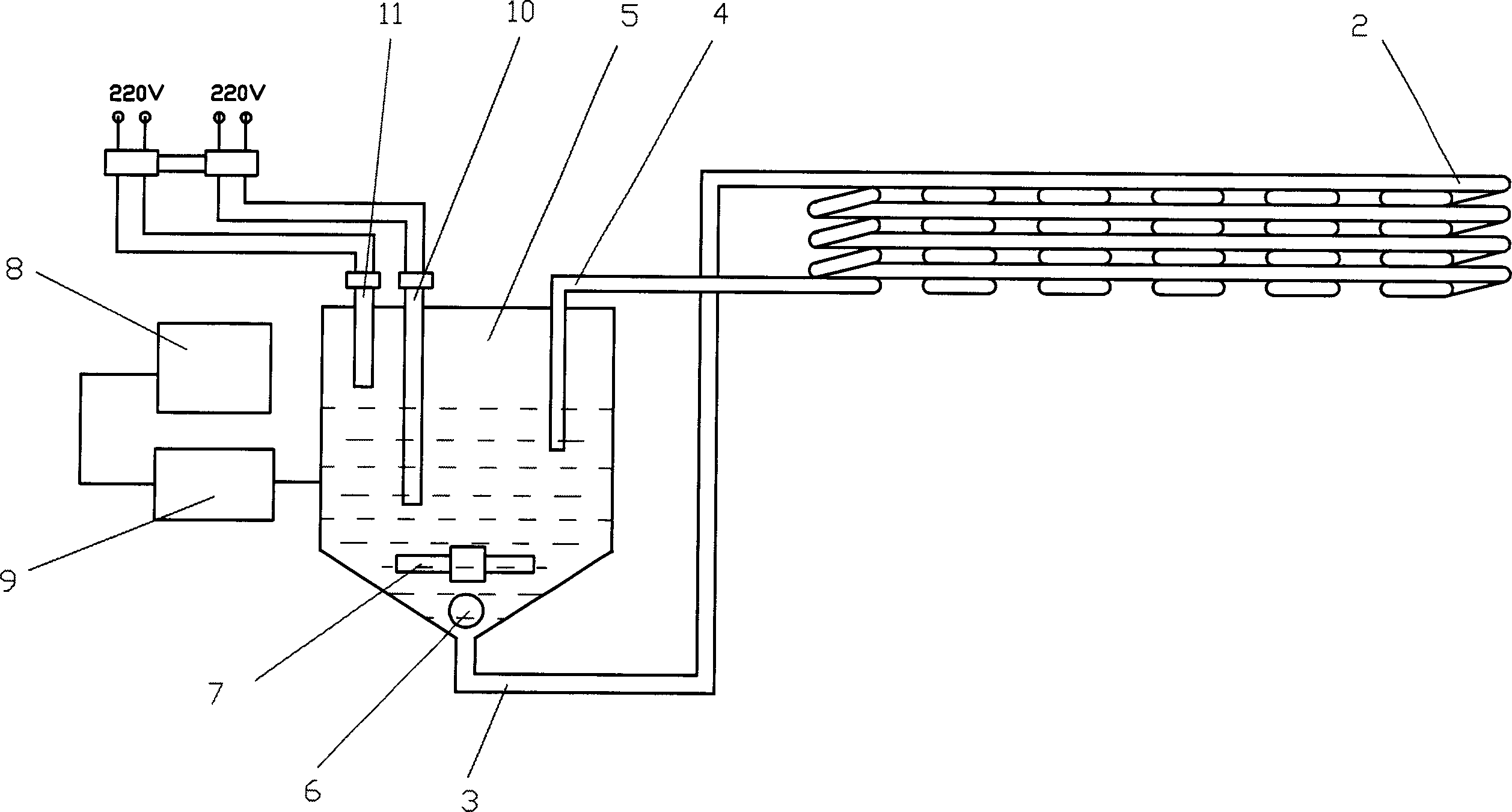

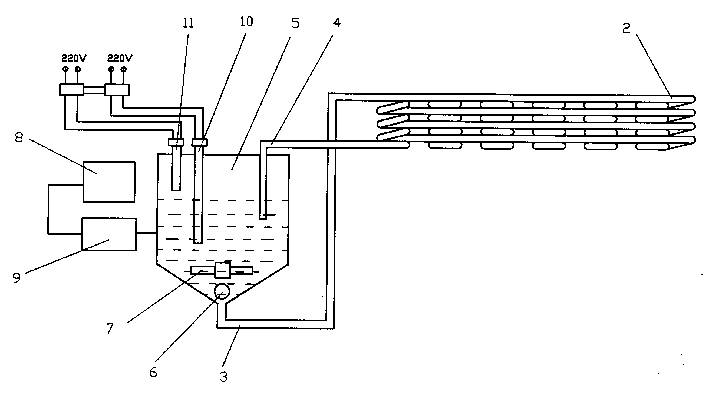

[0010] refer to figure 1 , figure 2 , an automatic continuous production track-type photobioreactor, comprising an illumination system 1, a reaction vessel 2, the reaction vessel 2 is a communication pipe of transparent light-transmitting material, has an inlet port 3 and an outlet port 4, and the inlet port 3 and a mixing tank 5 Connected, there is a mixed liquid agitator 7 at the bottom of the mixing tank 5, and a pump 6 is located at the inlet end 3; the connecting pipe is connected by a plurality of "U"-shaped pipes, and the reaction vessel is vertically crossed by multi-layer connecting pipes The illumination system is located in the "well"-shaped space formed by the vertical stacking of connecting pipes; the outlet end 4 of the reaction vessel 2 is also connected to the mixing tank 5 to form a loop; the culture solution storage tank 8 passes through the ball valve automatic controller 9 Connected to the mixing tank 5; the pH measuring and controlling instrument 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com