Welding system

A welding system and interface technology, which is applied in the direction of welding power supply, welding power supply, welding equipment, etc., can solve the problems of long connecting wire length and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

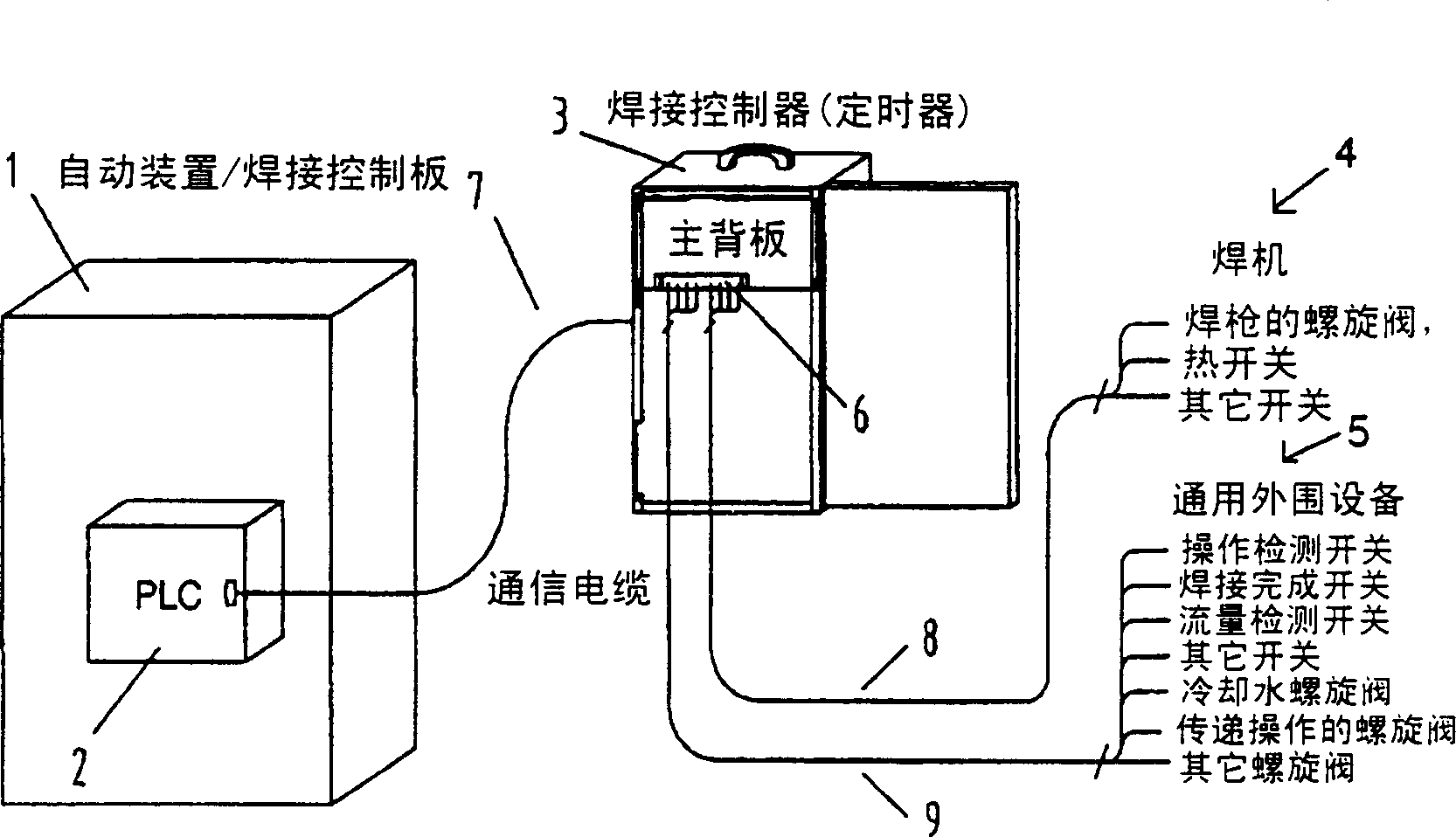

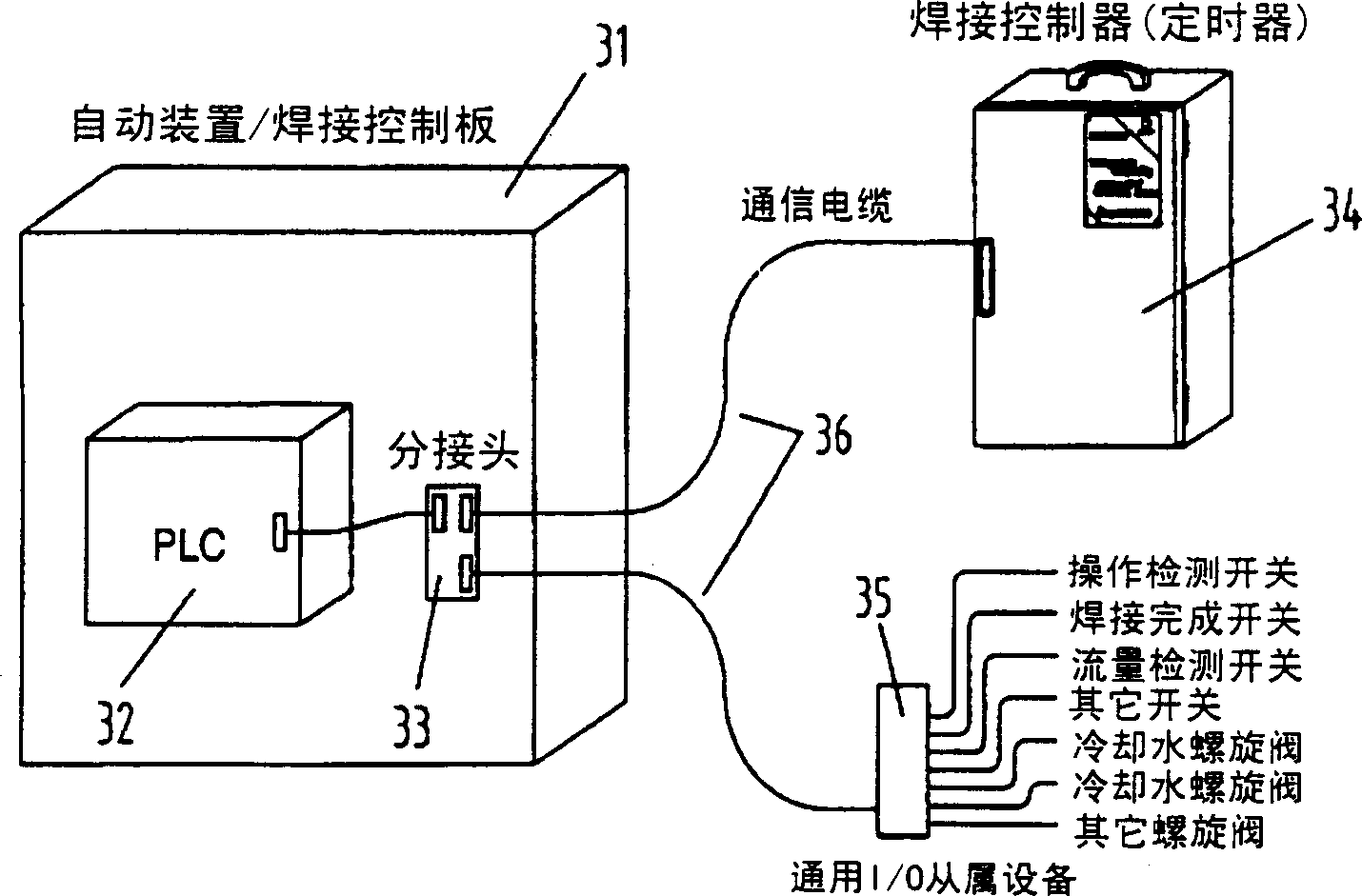

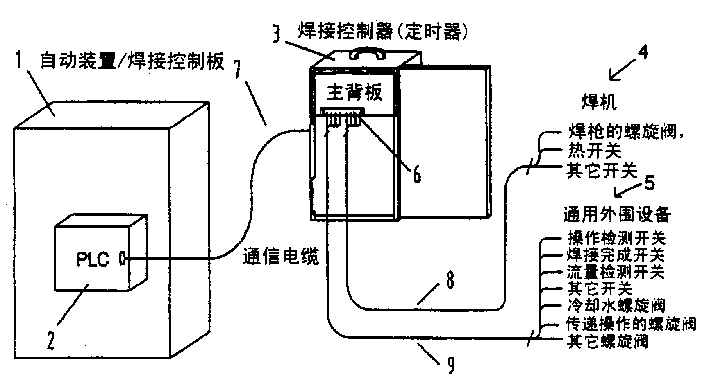

[0011] A welding controller according to a preferred embodiment of the present invention will be described below with reference to the accompanying drawings. figure 1 is a schematic diagram showing the configuration of an FA system suitable for operating the welding controller of the present invention.

[0012] exist figure 1 Among them, 1 represents the automatic device / welding control board, and 2 represents the PLC placed on the automatic device / welding control board 1. 3 indicates a timer used as a welding controller, 4 indicates a welding machine to be controlled by the welding controller 3, 5 is a general peripheral device placed on the periphery of the welding machine 4, and correctly represents such as a screw valve for controlling cooling water, a flow detection switch Peripheral equipment such as a screw valve for transmitting operation, a switch for inputting operation detection information, etc.

[0013] Between the PLC2 and the I / O interface (terminal block) 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com