Automatic controller for lowering pressure of high-pressure gas by volume expansion

An automatic control device, expansion and decompression technology, used in auxiliary non-electrical fluid pressure control and other directions, can solve problems such as large energy loss, and achieve the effects of high energy utilization, simple device composition and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

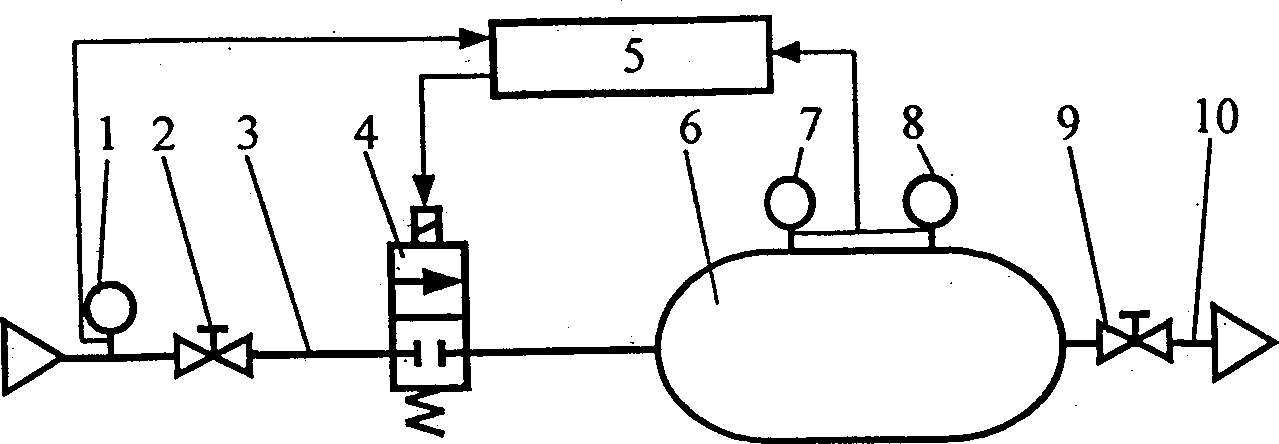

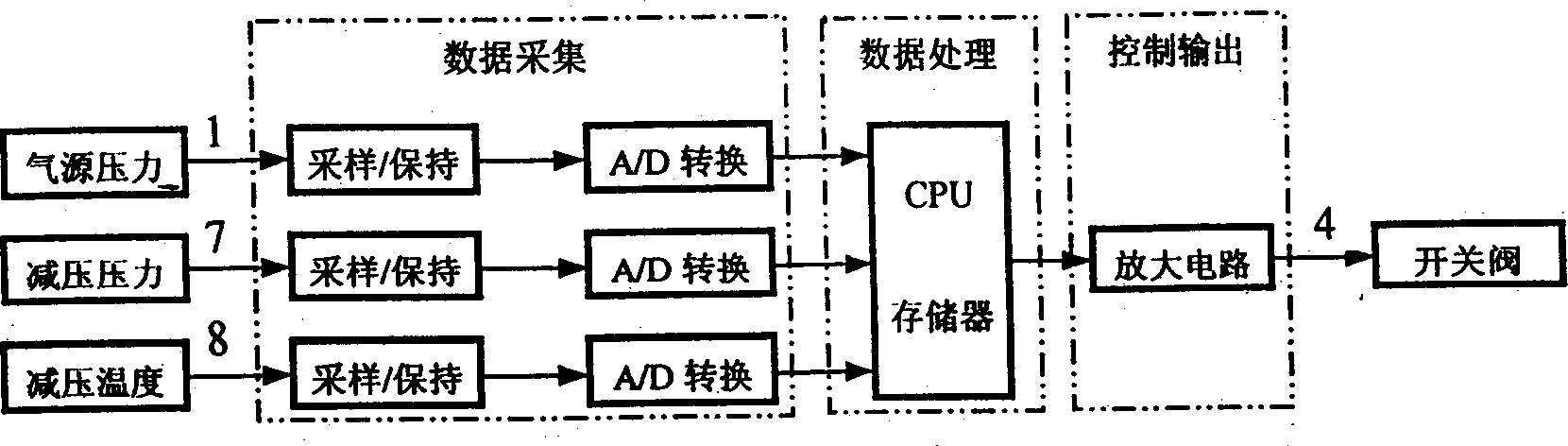

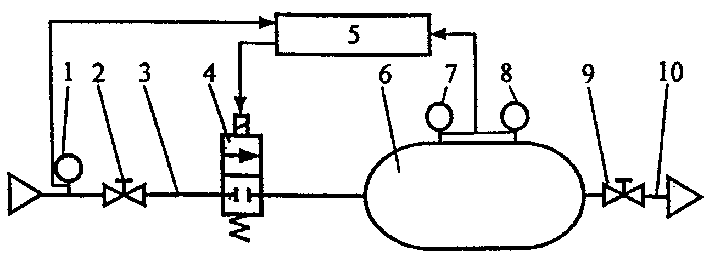

[0012] Such as figure 1 As shown, the high-pressure gas volume pressure reducing device is composed of a high-pressure pneumatic switch valve 4, a controller 5, a volume expansion vessel 6, a high-pressure stop valve 2, a pressure sensor and display instruments 1 and 7, a temperature sensor and a display instrument 8, and a low pressure The shut-off valve 9, the high-pressure pipeline and the joint 3, the low-pressure pipeline and the joint 10 are composed.

[0013] The air inlet of the high-pressure pneumatic switch valve 4 is connected to the high-pressure shut-off valve 2 through a joint and a high-pressure pipeline, the air outlet is connected to the inlet of the volume expansion vessel 6 through a joint and a high-pressure pipeline, and the control end wiring is connected to the output port of the controller 5 . The high-pressure pneumatic switch valve 4 is controlled by the control signal sent by the controller 5, which is used to control the period and time of the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com