Collagen used for deep-sea fish skin tissue engineering and its preparing process

A deep-sea fish skin and collagen technology, applied in the field of fish skin collagen, can solve the problems of limited collagen application and low degree of collagen purification, and achieve the effects of high purity, simple method and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

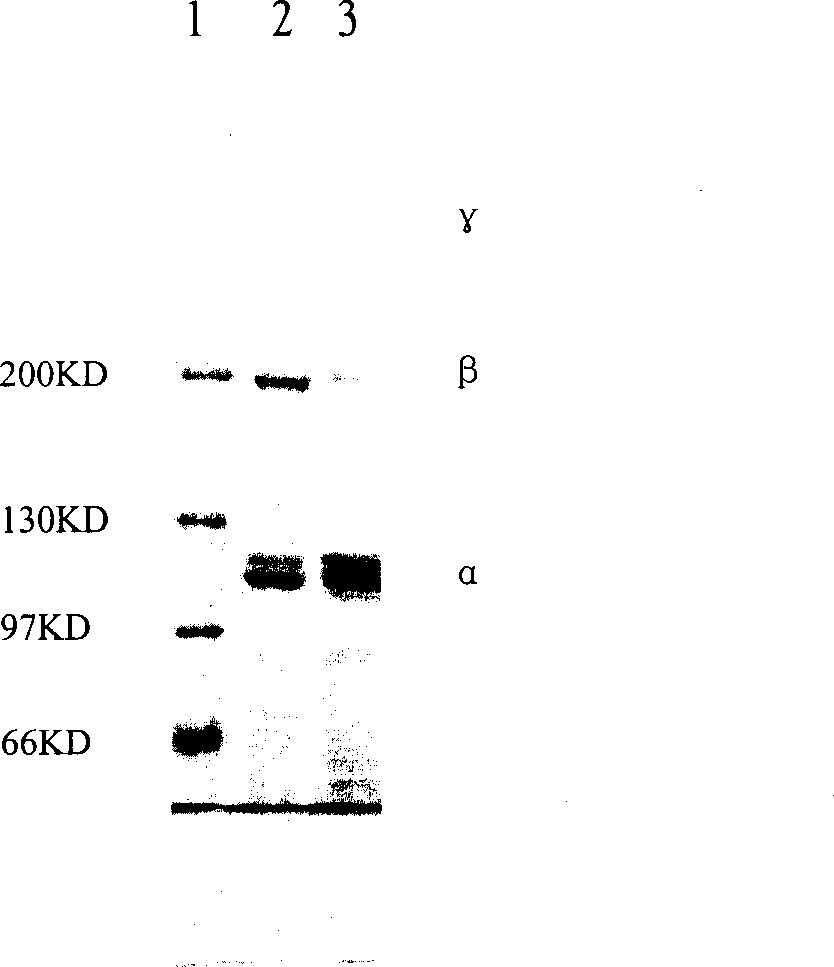

Image

Examples

Embodiment 1

[0024] Embodiment 1: preparation of fish skin collagen

[0025] 1. Clean the fish skin Soak 1 kg of frozen salmon skin in tap water at 4°C and rinse it clean, remove scales and subcutaneous tissue until there is no other solid matter in the soaking solution except the whole fish skin, and then use it Soak in deionized water and rinse 5 times.

[0026] 2. Alkaline treatment of fish skin with 5% Na 2 CO 3 Soak 10 liters of solution at 4°C and soak (1) the fish skin after treatment for 1 week, and replace it with 3% Na every day. 2 CO 3 solution. The fish skin after the alkali treatment is fully cleaned with deionized water until the pH is about 7.

[0027] 3. Restricted enzymatic hydrolysis of fish skin Dissolve the fish skin treated in (2) in 5 liters of 1.0 M acetate buffer, add 1.0% trypsin, enzymolyze at 4° C. for 1 day, and filter with gauze. The residue was subjected to restriction enzymatic hydrolysis again, and the steps were the same as above, and the ...

Embodiment 2

[0030] Embodiment 2: preparation of fish skin collagen

[0031] 1. Clean the fish skin. Soak 1 kg of frozen salmon skin in tap water at 1-10°C and rinse it clean. Remove scales and subcutaneous tissue until there is no other solid matter in the soaking solution except the whole fish skin. Soak and rinse with deionized water 5 times.

[0032] 2. Alkaline treatment of fish skin with 1% Ca(OH) 2Soak 10 liters of solution at 1-10°C (1) for 1 week to treat fish skin, and replace 1% Ca(OH) once a day 2 solution. The fish skin after the alkali treatment is fully cleaned with deionized water until the pH is about 7.

[0033] 3. Restricted enzymatic hydrolysis of fish skin Dissolve the fish skin treated in (2) in 5 liters of 1.0M acetate buffer, add 1.0% pepsin, and enzymatically hydrolyze it at 1-10°C for 2 days. filter. The residue was subjected to restriction enzymatic hydrolysis again, and the steps were the same as above, and the two filtrates were combined.

[0...

Embodiment 3

[0035] Embodiment 3: preparation of salted fish skin collagen

[0036] 1. Clean the fish skin Soak 1 kg of frozen salmon skin in tap water at 5°C and rinse it clean, remove scales and subcutaneous tissue until there is no other solid matter in the soaking solution except the whole fish skin, and then use it Soak in deionized water and rinse 5 times.

[0037] 2. Alkali treatment of fish skin Fish skin was salted with NaCl (1:1 w / w) for 7 days. The fish skin after the alkali treatment is fully cleaned with deionized water until the pH is about 7.

[0038] 3. Restricted enzymatic hydrolysis of fish skin Dissolve the fish skin treated in (2) in 5 liters of 1.0 M acetate buffer, add 2.0% pepsin, enzymolyze at 5° C. for 2 days, and filter with gauze. The residue was subjected to restriction enzymatic hydrolysis again, and the steps were the same as above, and the two filtrates were combined.

[0039] 4. Purify collagen. Centrifuge the above filtrate at 10,000rpm at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com