Lens fixing device for glasses without frame

A fixing device and technology for rimless glasses, applied in glasses/goggles, lens components, optics, etc., can solve problems such as difficulty in providing strong fastening force, increased gap between lenses and screws, and excellent rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

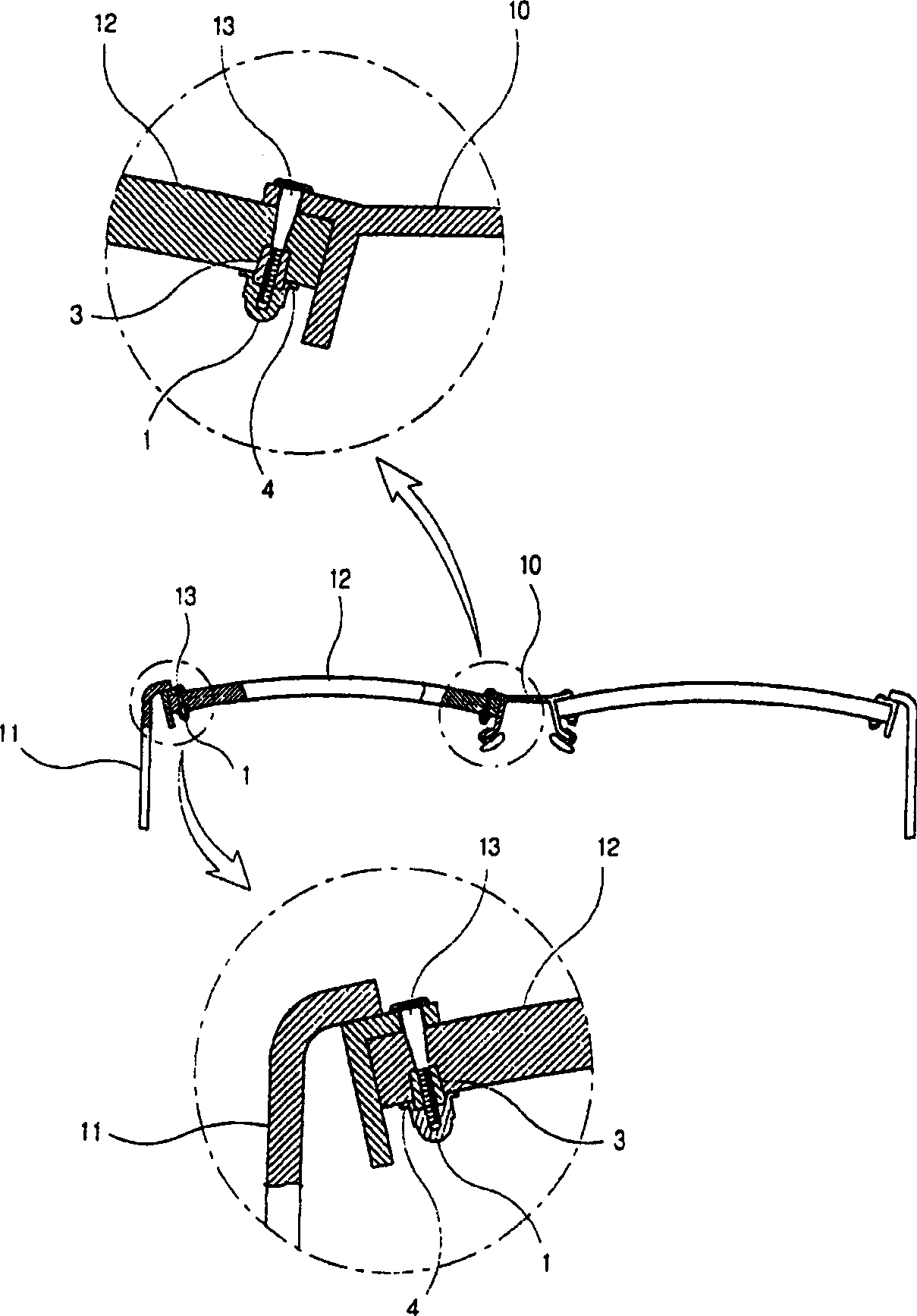

[0020] Reference will now be made in detail to a preferred embodiment of the invention, an example of which is illustrated in the accompanying drawings. Wherever possible, the same reference numerals will be used throughout the drawings and description to refer to the same or like parts.

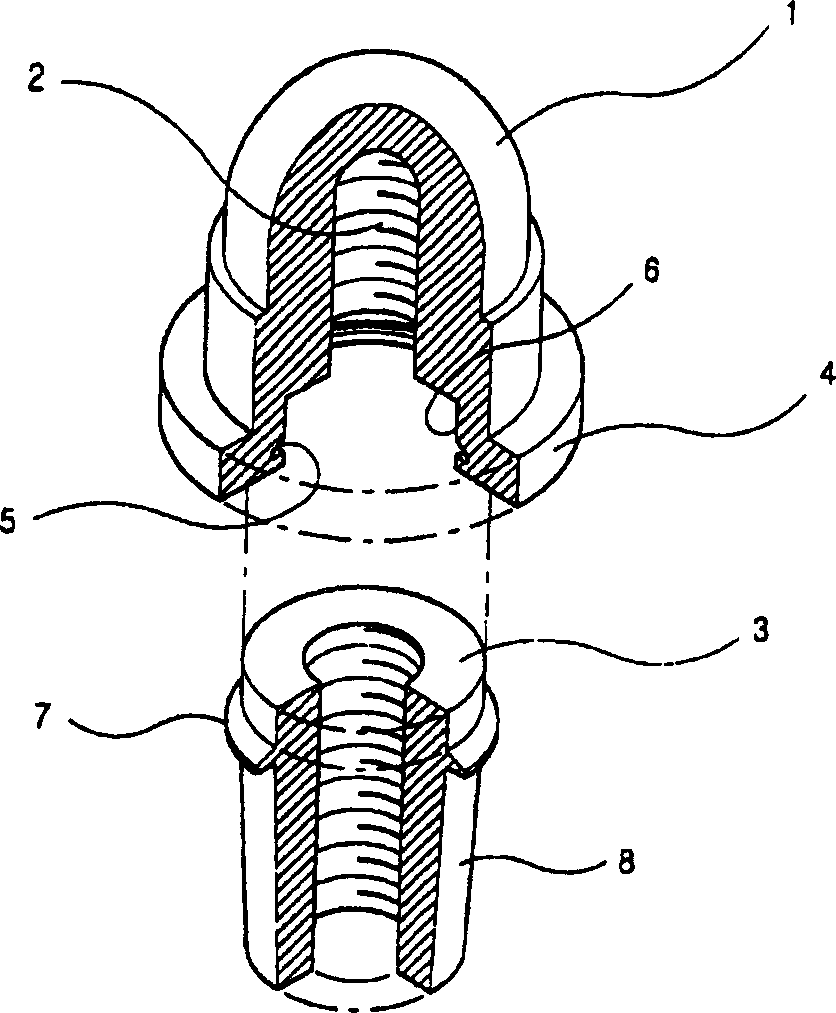

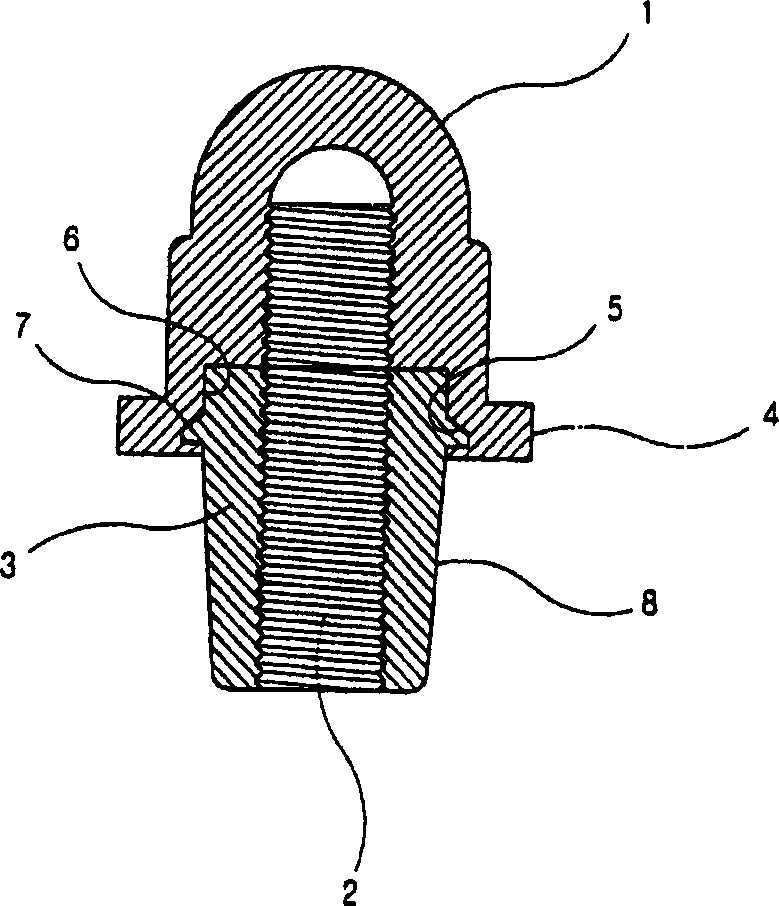

[0021] figure 1 is a cutaway perspective view illustrating the lens fixing device for rimless eyeglasses according to the first embodiment of the present invention; figure 2 is description figure 1 A cross-sectional view of one assembled state of the lens fixture in .

[0022] A lens fixing device according to a first embodiment of the present invention includes a first fixing element and a second fixing element. The first fixing element is made of soft synthetic resin and has a guide portion 3 and a tapered portion 8 . from image 3 The guide portion 3 is formed at the lower end of the first fixing element as viewed in the plane. The tapered portion 8 decreases in diameter towards th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com