Method of regulating water sucking sectino of deep oil layer

A water-absorbing profile and deep-seated technology, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as difficult injection, high injection pressure, and inability to achieve deep profile control, so as to improve crude oil recovery Yield, water cut reduction, and the effect of expanding the swept section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

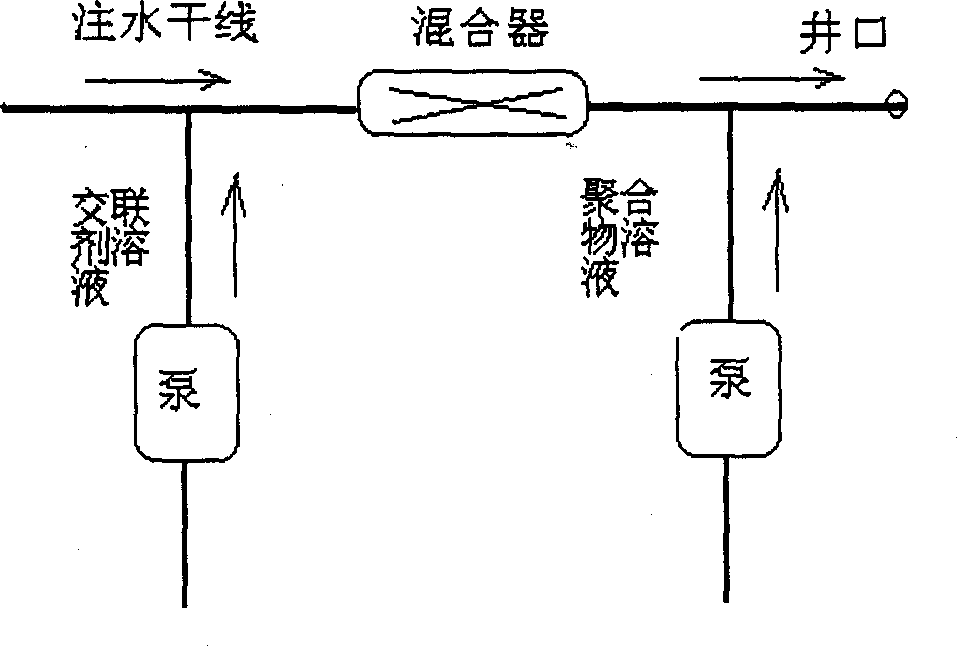

[0017] For the on-site preparation and injection process of the profile control agent system, please refer to the attached figure 1 The process:

[0018] First, pump 20-100% aluminum citrate solution (cross-linking agent) into the main water injection line, and flow through the mixer together with injection water (clean water or sewage) to fully disperse the cross-linking agent; %, the polyacrylamide (polymer) solution with a molecular weight of 100-30 million is imported into the main water injection line with a pump, and the concentration of the polymer and the crosslinking ratio are controlled, and mixed and prepared to become the profile control agent dispersion system for profile control of the present invention. The profile control agent is injected into the water injection well (the above method is the so-called single liquid injection method).

[0019] The temperature of the mixing process is controlled at 10-90°C, and the pH of the injected water is 4-9. Mine test o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com