Golf club head and its surface treatment method

A technology for golf club heads, metal surfaces, applied to golf balls, golf clubs, rackets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

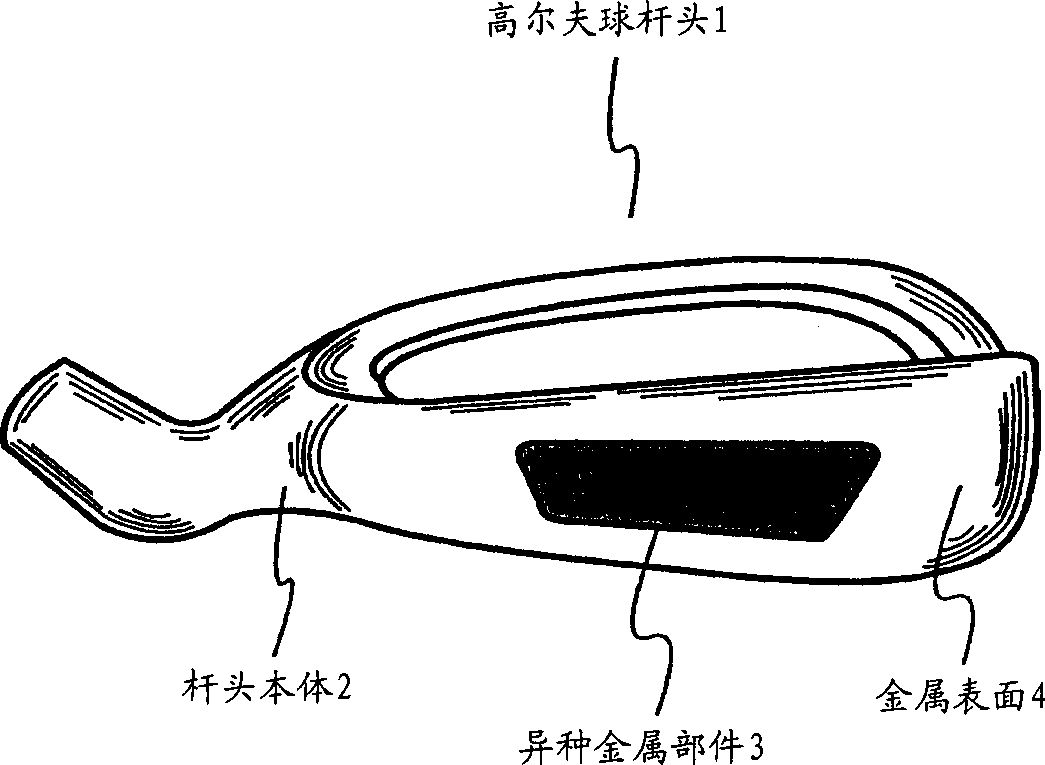

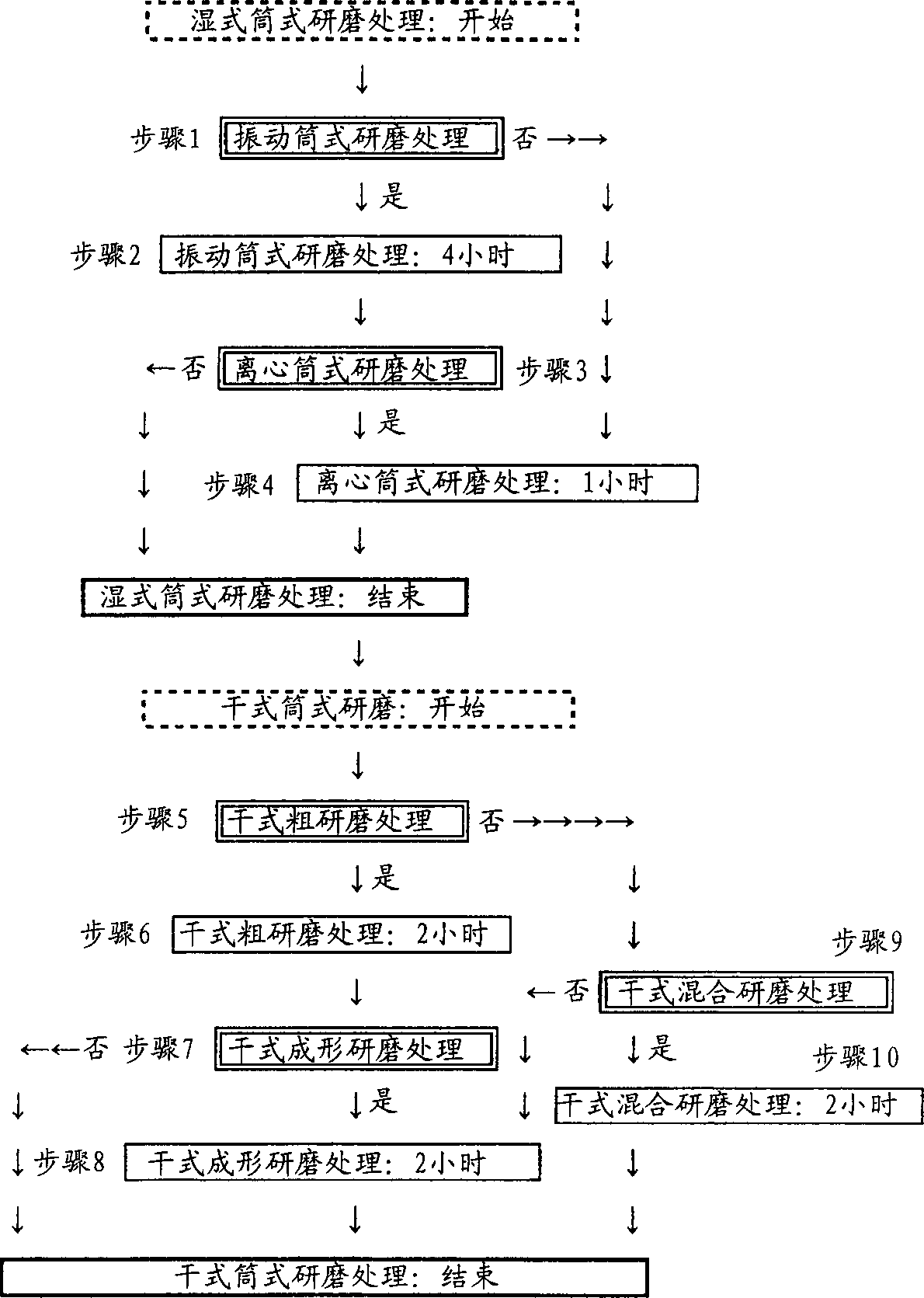

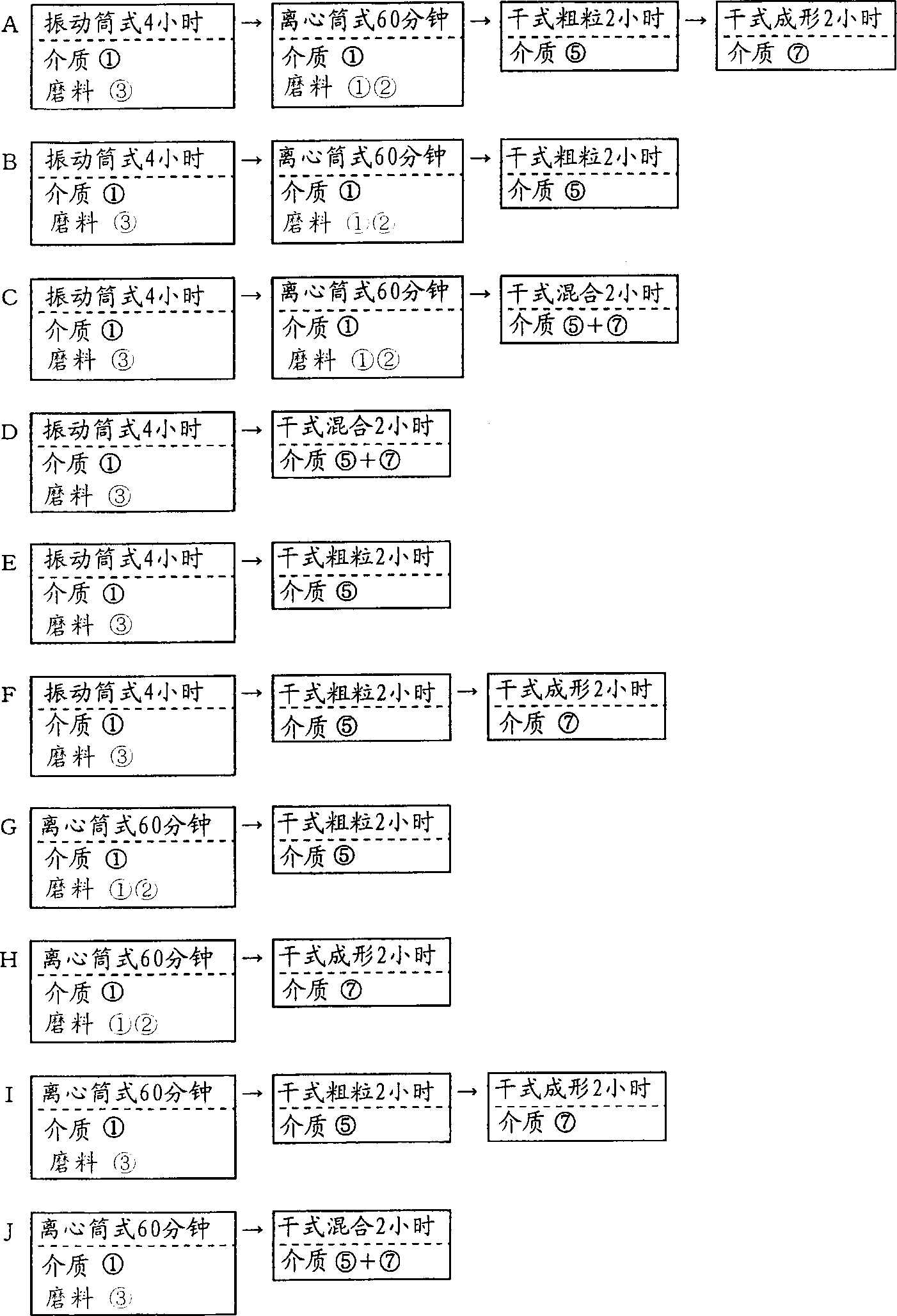

[0058] figure 1 It is a view of forming the golf club head 1 of this embodiment into an iron club head. The golf club head 1 of this embodiment is constituted by embedding a dissimilar metal member 3 formed of tungsten steel in a portion corresponding to a "sole" of a club head body 2 formed of stainless steel. The present invention implements base surface grinding treatment on the golf club head 1, and then image 3 Each grinding method shown is generally implemented by "wet cylinder grinding process" and "dry cylinder grinding process".

[0059] First, the formation of the golf club head 1 and the "surface treatment" performed on the golf club head 1 will be described.

[0060] The golf club head 1 of this embodiment is composed of the head body 2 and the different metal member 3 as described above. The aforementioned club head body 2 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com