Hydraulic driving rotating disk

A technology for driving discs and turntables, applied in the direction of fluid pressure actuating devices, etc., which can solve the problems of complex hydraulic systems, high costs, and difficulty in applying daily tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

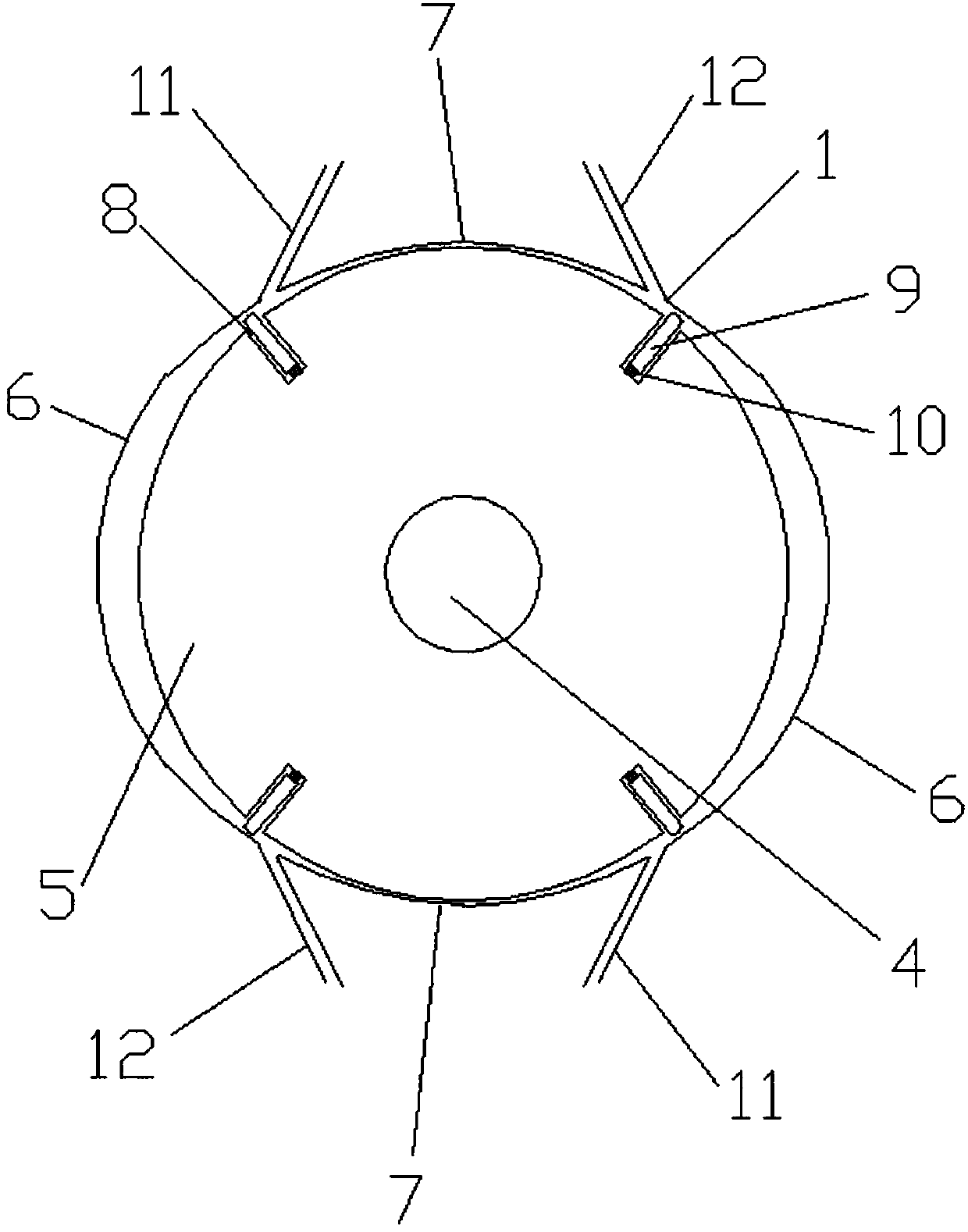

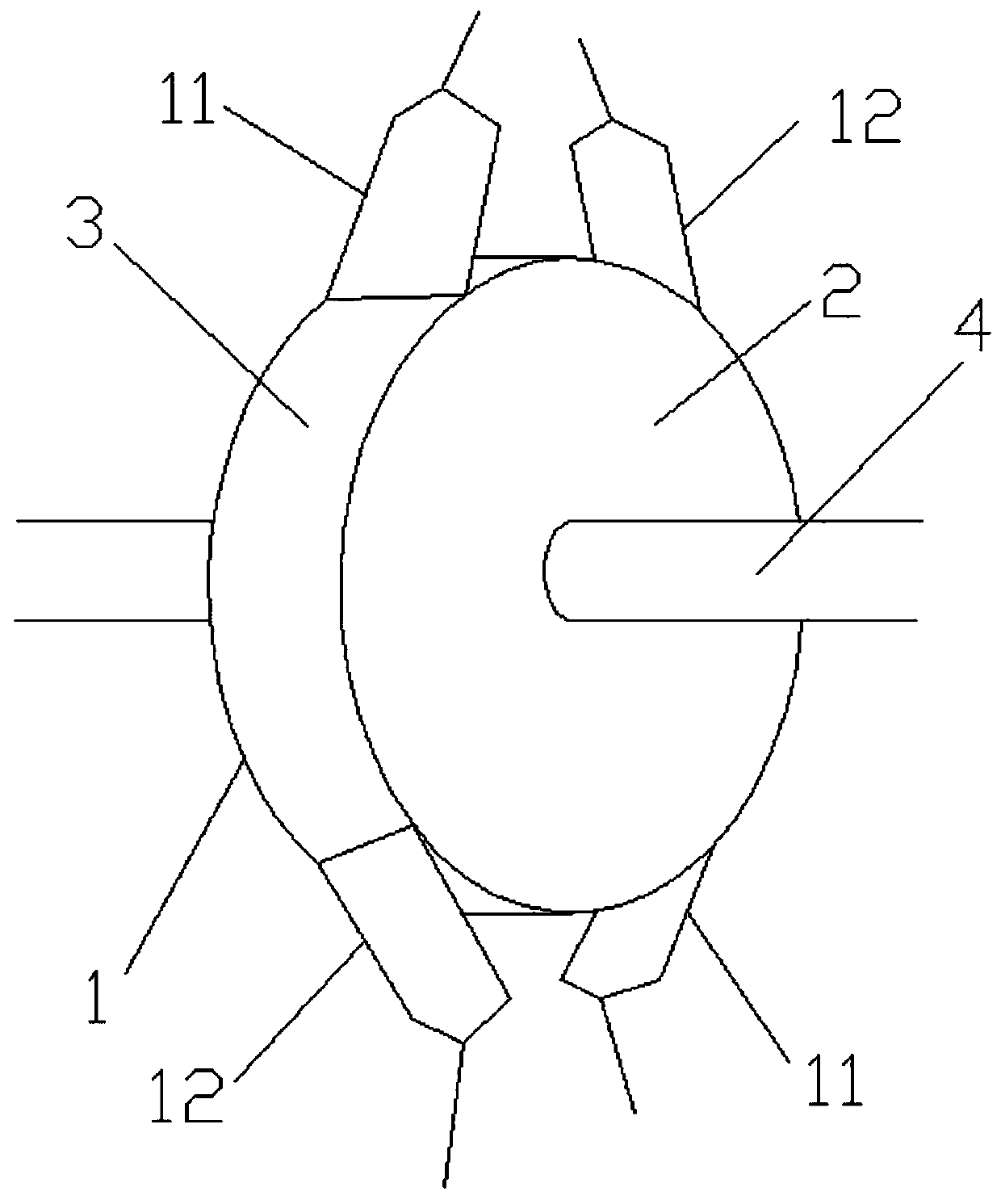

[0014] Combine below figure 1 with figure 2 The technical solution of the present invention will be described in further detail, but not limited to this description.

[0015] A hydraulically driven turntable, comprising an annular side plate 3, cover plates 2 are provided on both sides of the side plate 3, and the two cover plates 2 and the side plates 3 together form a closed casing 1; the two cover plates 2 are Correspondingly, a drive shaft 4 is threaded through the drive shaft 4, and a drive disc 5 is fixedly sleeved on the drive shaft 4. The drive disc 5 is located in the housing 1 and matches the size of the housing 1; the side plate 3 is provided with at least one power unit , the power unit includes a driving section 6 and a traveling section 7, the driving section 6 includes an arc-shaped side plate 3, and there is a gap between the driving section 6 and the driving disc 5; the starting end of the driving section 6 communicates with a liquid inlet pipe 11 , the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com