Wrap spring shade operator

A technology of winding springs and helical springs, which is applied in the field of devices for operating and positioning a blackout curtain, which can solve the problems of increased step effect and inability to be firm and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

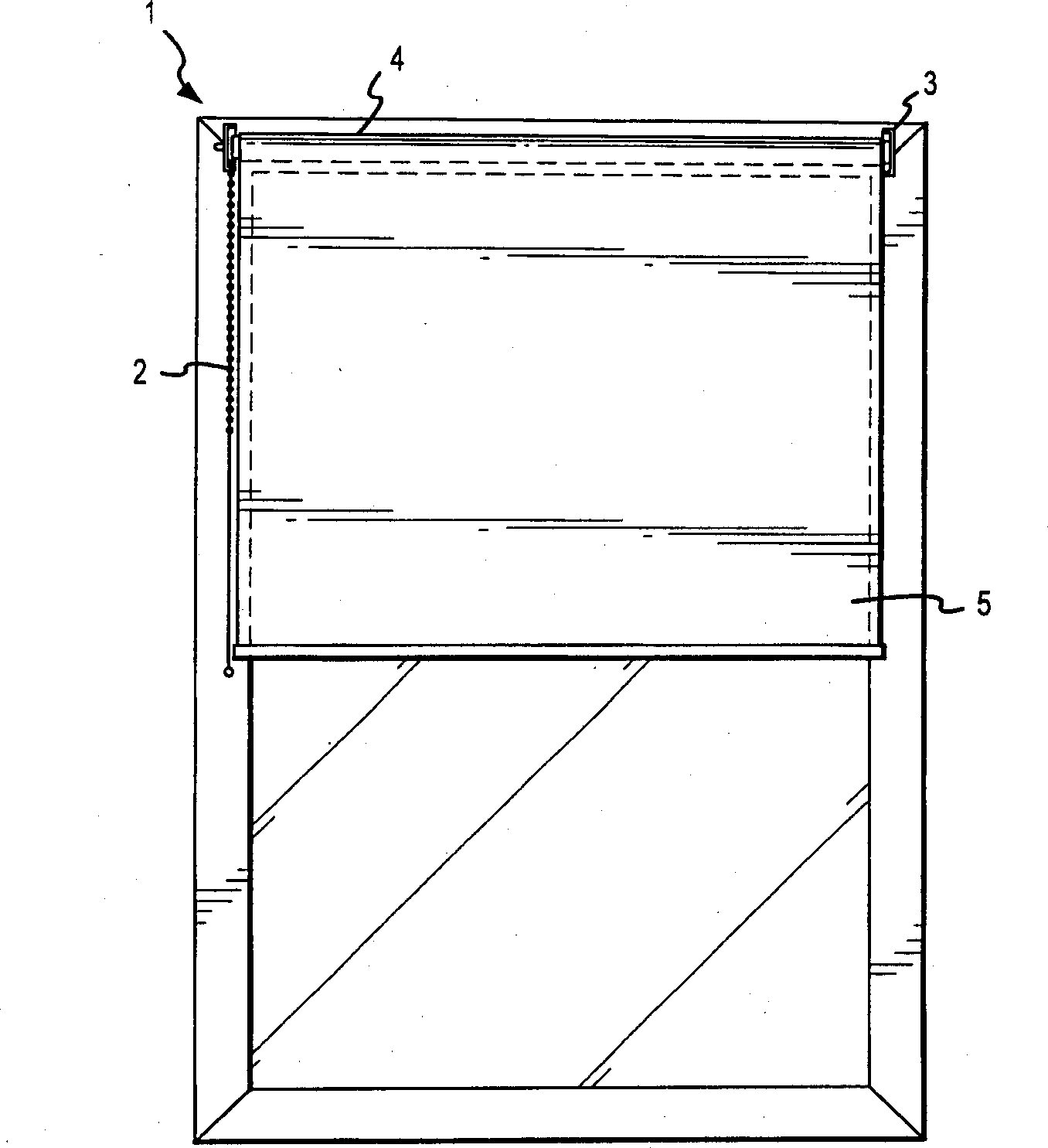

[0022] The preferred invention includes a wrap spring clutch system that can be used to control the positioning of any object, device, material, shade, door, and / or the like, wherein the system substantially eliminates or reduces stress during operation of the system. ladder effect. according to figure 1 , which shows a front view of a preferred embodiment of the system installed in a window. The preferred embodiment generally comprises: a shade operator 1, which has a chain 2 for operating the shade operator 1; lowering; a spool 4 on which the shade 5 can be wound; and a rear support 3 which can hold the spool 4 between the shade operator 1 and the support 3 during operation of the invention. The shade roller 4, shade 5 and rear bracket 3 are preferably of conventional construction and are co-located in a conventional window frame.

[0023] Although a preferred embodiment of the present invention describes the operation of a shade, those skilled in the art will appreciate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com