Heater support structure and furnace for forming sheet glass

A support structure and heater technology, applied in electric furnace heating, heating elements, glass production, etc., can solve problems such as difficult temperature distribution and heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, preferred embodiments of the heater support structure and the heating furnace for glass sheet bending molding according to the present invention will be described in detail with reference to the accompanying drawings.

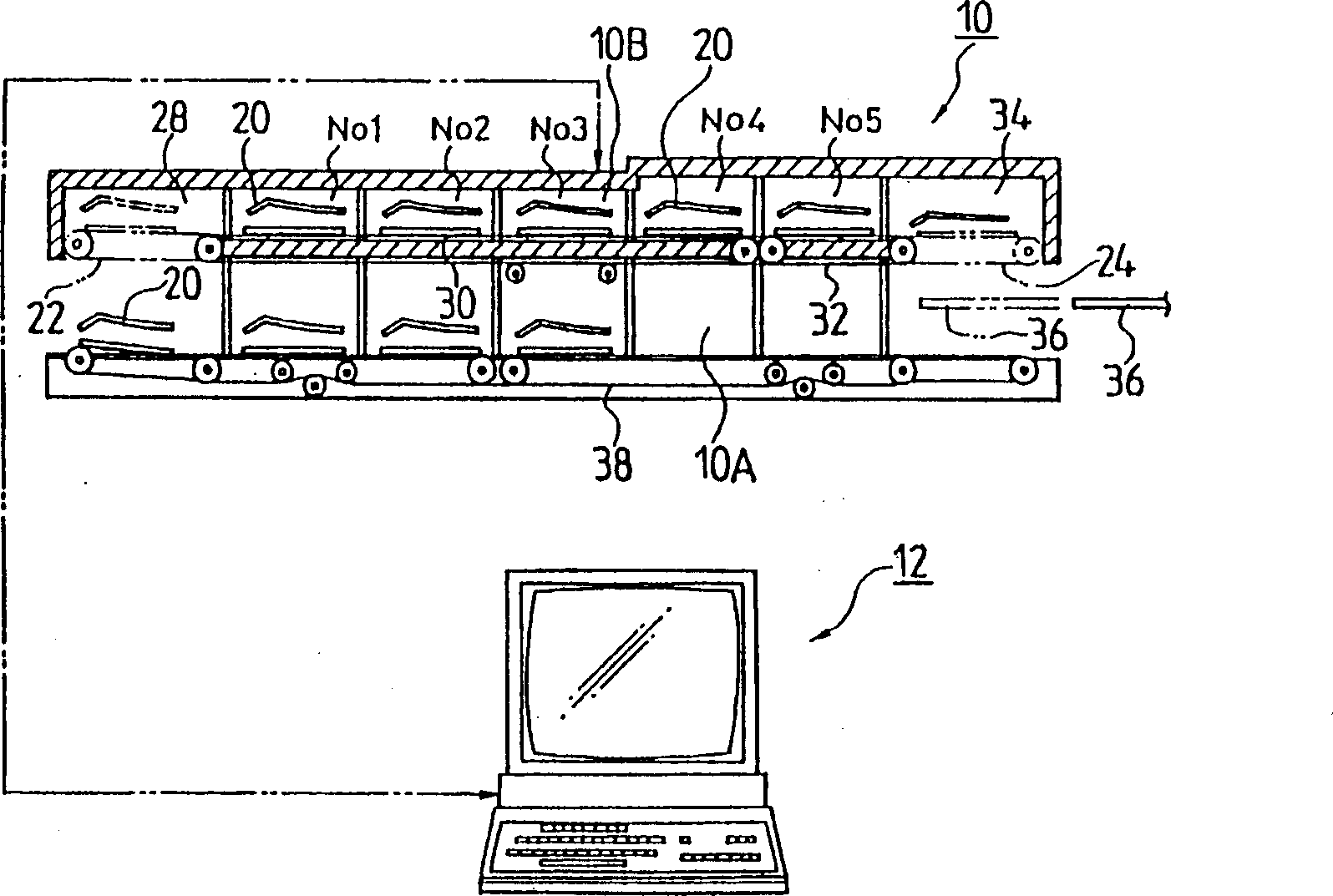

[0015] figure 1 It is an overall configuration diagram showing an example of a blank glass bending apparatus for laminated glass to which the heater of the present invention is applied. In the example of the present invention, the blank glass bending and forming device 10 for laminated glass is a double-layer structure device, and the bottom part and the top part are connected by elevators 22 and 24 at both ends thereof. The bottom portion of the blank glass bending apparatus 10 for laminated glass constitutes a return path 10A of the bending die 20, and the upper portion constitutes a heating furnace 10B.

[0016] The heating furnace 10B is divided into five zones along the conveying direction of the glass plate, that is, heating zones No....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap