Window mounted in roof and mounting frame for mounting roof perspective structure

A technology for installing brackets and windows, applied in the field of windows, can solve the problems of increased packaging volume, inconvenience, damage to the installation brackets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

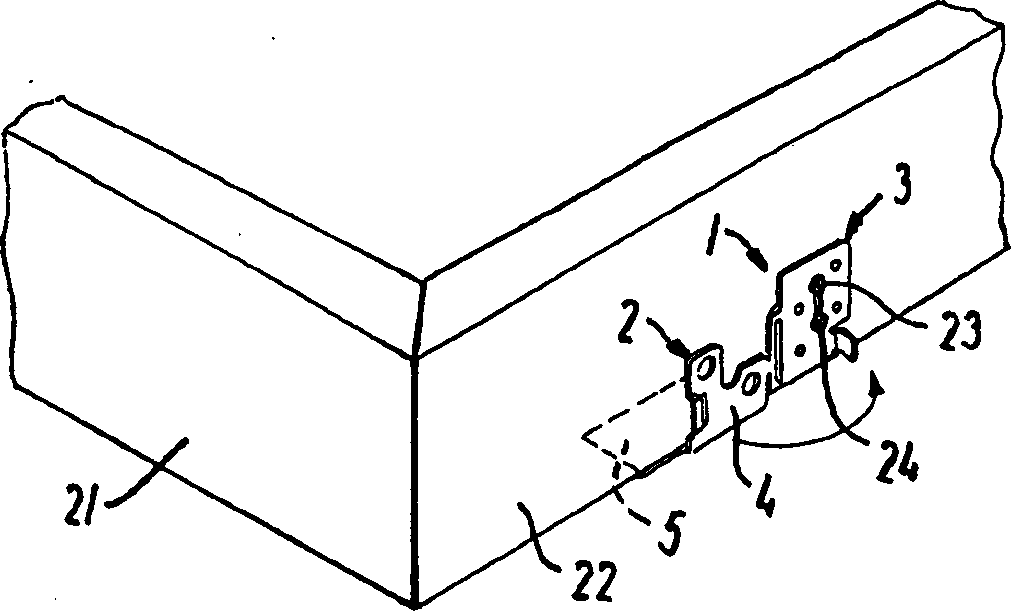

[0027] figure 1 A mounting bracket generally designated by the numeral 1 is illustrated, comprising corner bracket members 2 and a generally plate-shaped bottom member 3 . The angle bracket component 2 includes a first bracket piece 4 and a second bracket piece 5 extending from the lower end of the first bracket piece 4 approximately at right angles and integrally connected with the first bracket piece 4 . The corner bracket member 2 and the bottom member 3 are connected together by a connecting portion 6 extending from the first side end 7 of the first bracket piece 4 of the corner bracket member 2 to the first side end 8 of the bottom member 3 . The connection portion 6 includes a connection area 9, the two ends 9a, 9b of the connection area 9 are integrally connected with the first side end 8 of the bottom member 3, and the middle part 9c is connected with the first support piece 4 of the corner support member 2. The first side end 7 is connected in one piece, so that a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com