Ink remaining amount measuring device, ink-jet recorder comprising same, ink remaining amount measuring method, and ink cartridge

一种水平检测、喷墨记录的技术,应用在印刷等方向,能够解决噪音敏感、噪音的影响、难以检测等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the present invention will be described in detail with reference to the embodiments of the present invention. The following embodiments do not limit the invention in the claims, and the combination of all the features described in the embodiments is not always indispensable for the solution means of the present invention.

[0045] An ink level detection unit according to an embodiment of the present invention will be described below with reference to the accompanying drawings.

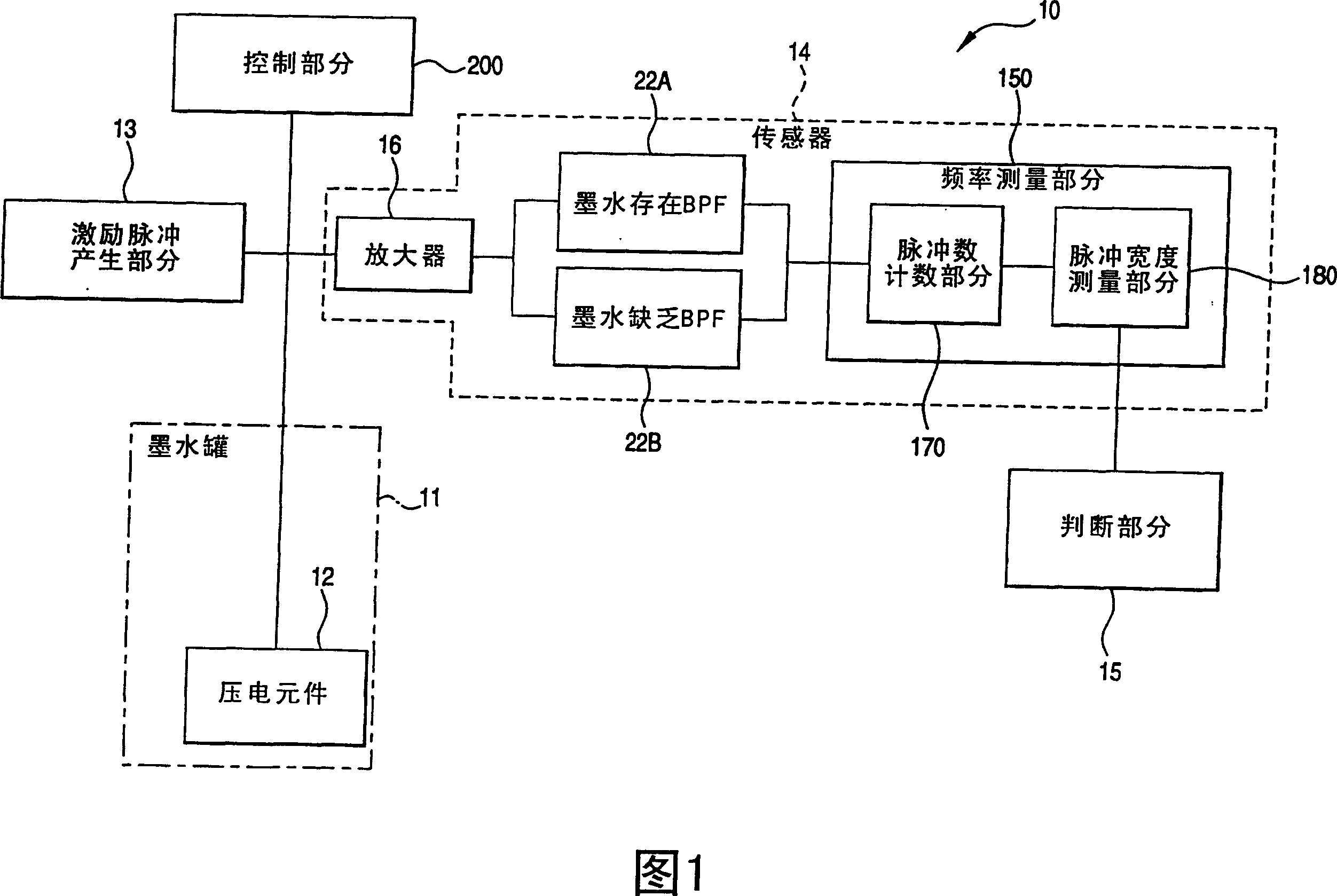

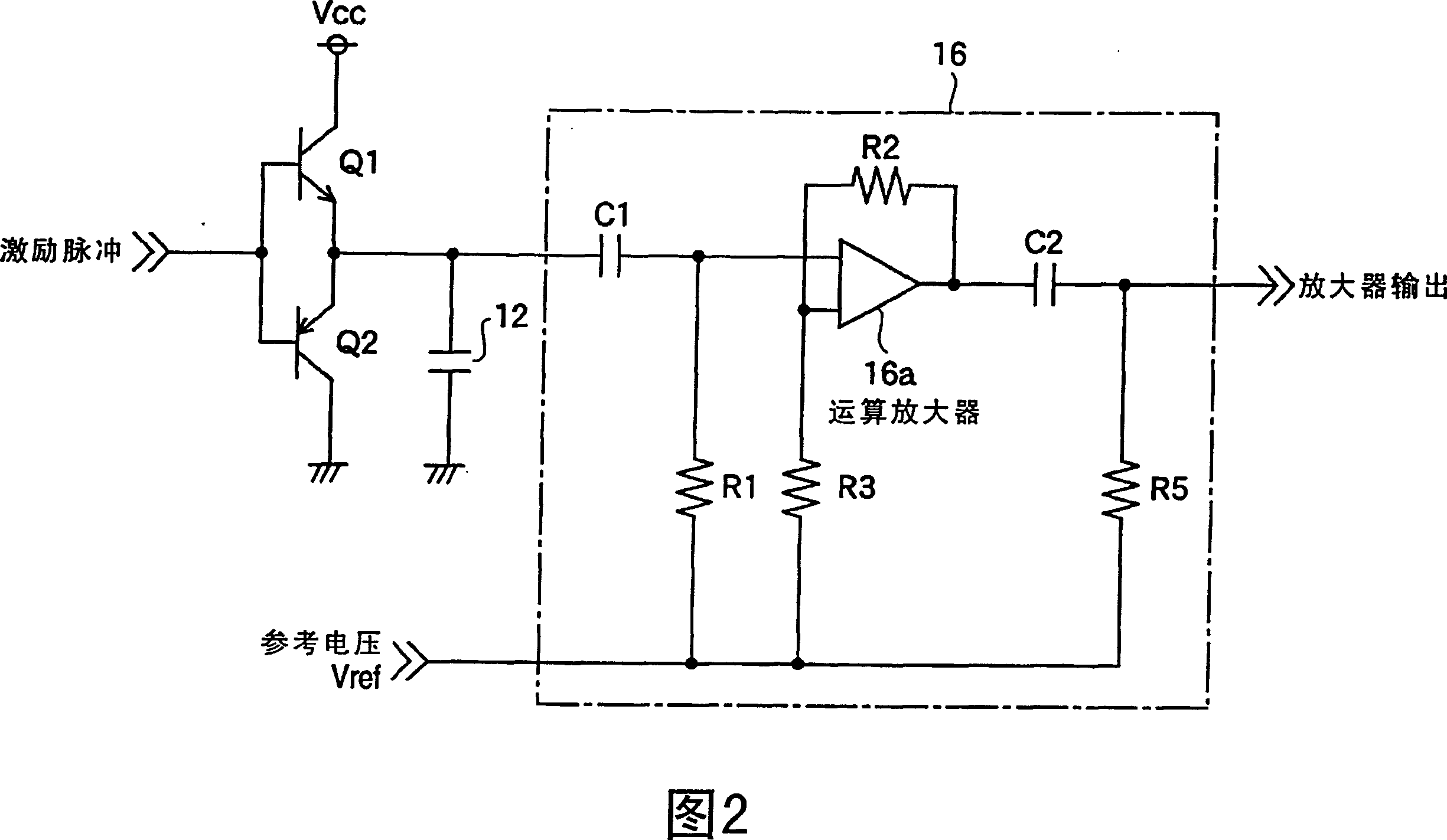

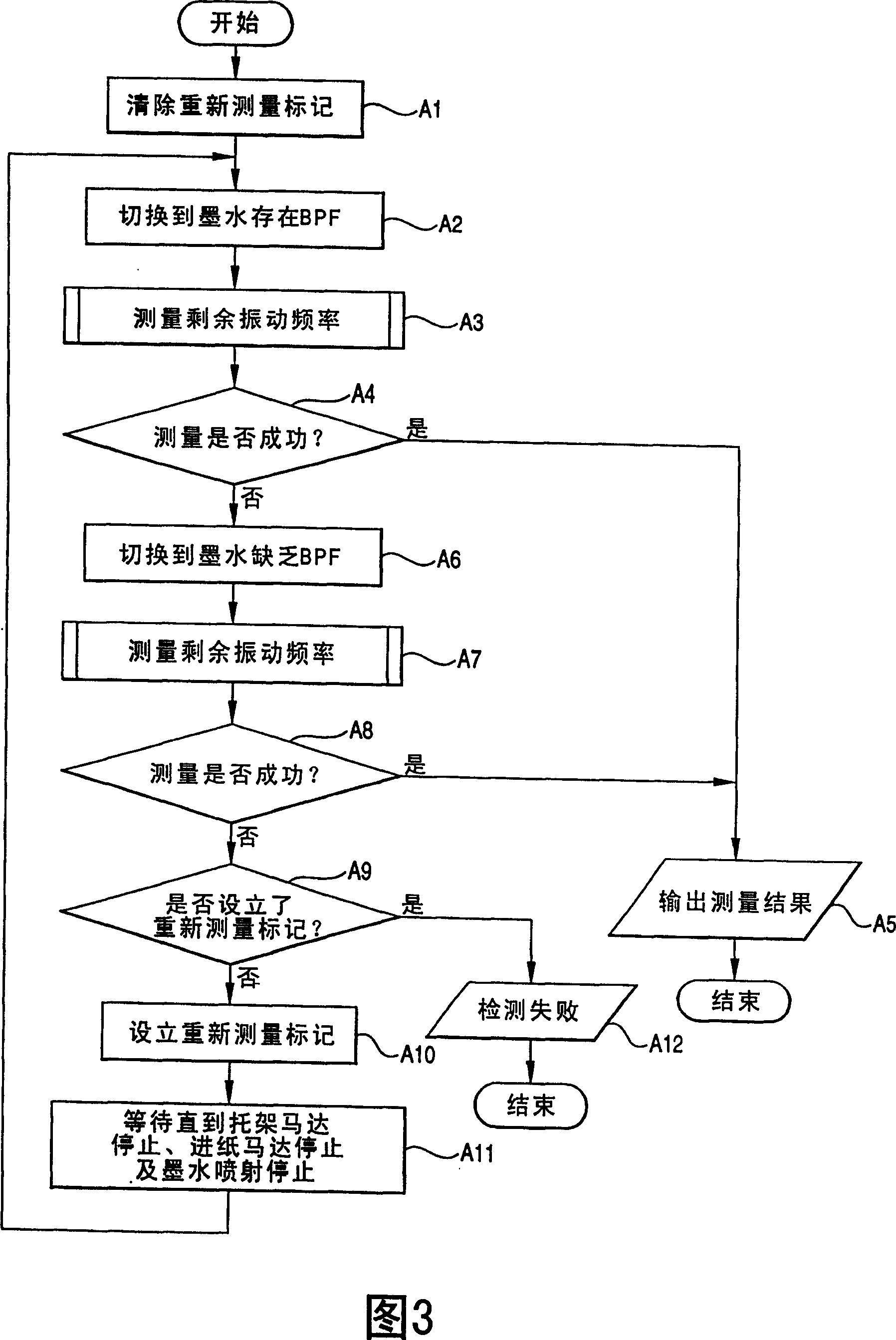

[0046] FIG. 1 shows the configuration of an ink level detection unit according to a first embodiment of the present invention. In FIG. 1, an ink level detection unit 10 includes a piezoelectric element 12 that functions as a vibrating element, provided for detachably mounted on a cartridge-type ink tank 11 on an inkjet recording apparatus (inkjet printer); An excitation pulse generating section 13 that applies an excitation pulse to this piezoelectric element 12; a sensor 14 that d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com