Producing method for H-shape spanner

A manufacturing method and wrench technology, applied to metal processing equipment, etc., can solve problems such as uncomfortable grip, no manufacturing method, and difficult control of deformation, and achieve the effect of cost-effectiveness and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific manufacturing method, steps, features and effects of the manufacturing method of the work wrench according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

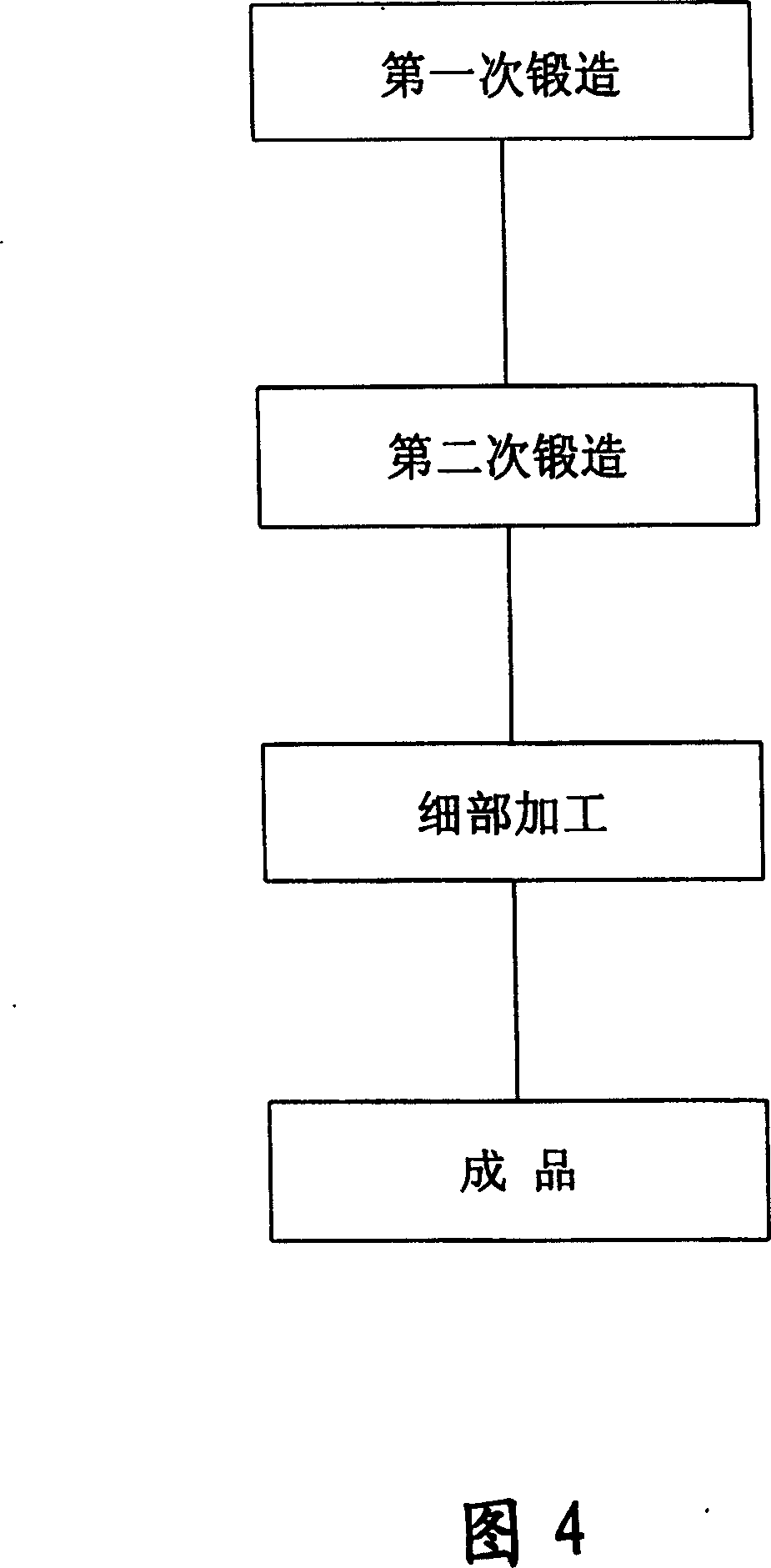

[0039] Please refer to Fig. 4 and shown in Fig. 5, the manufacturing method of the work wrench of the present invention mainly comprises the following process steps:

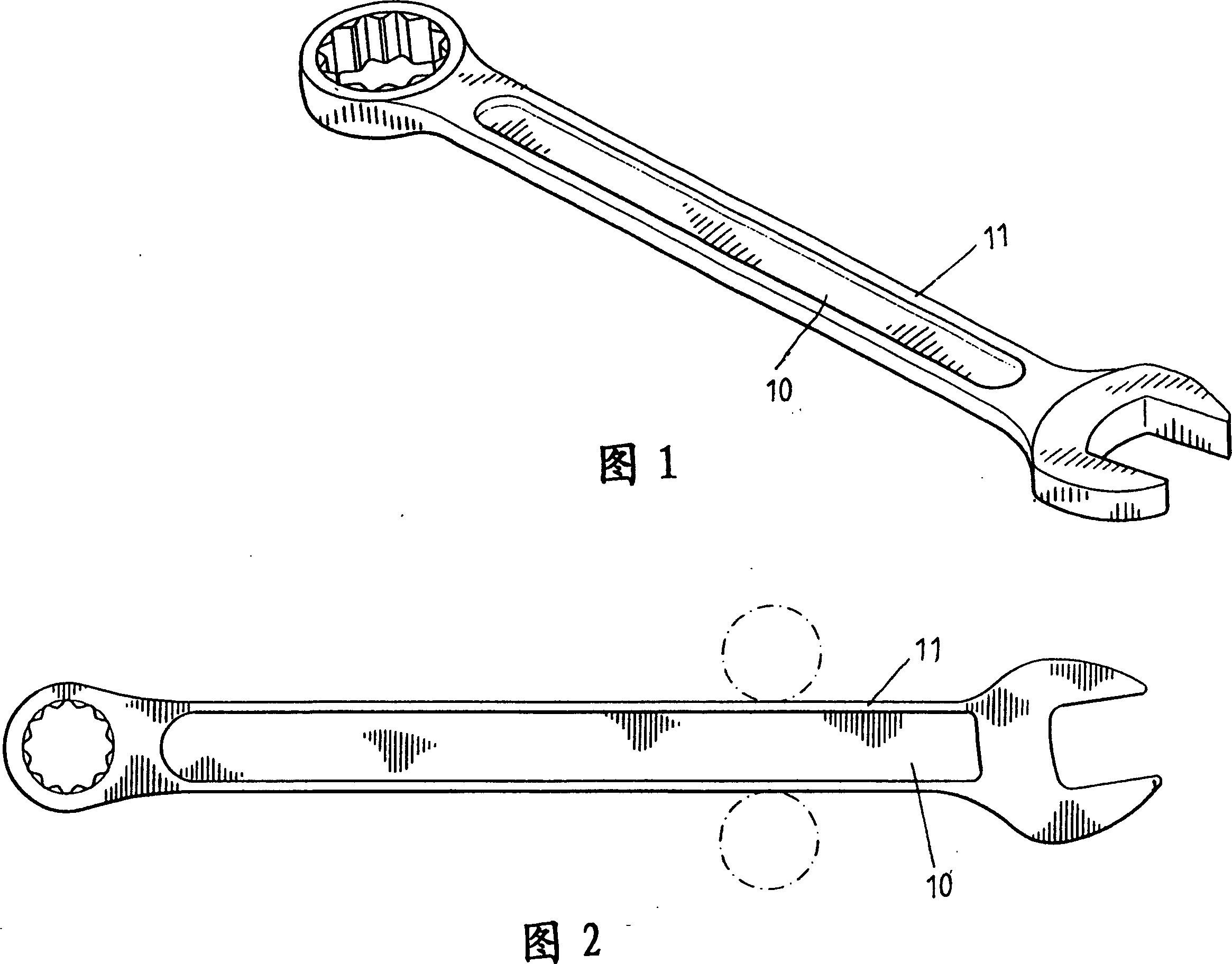

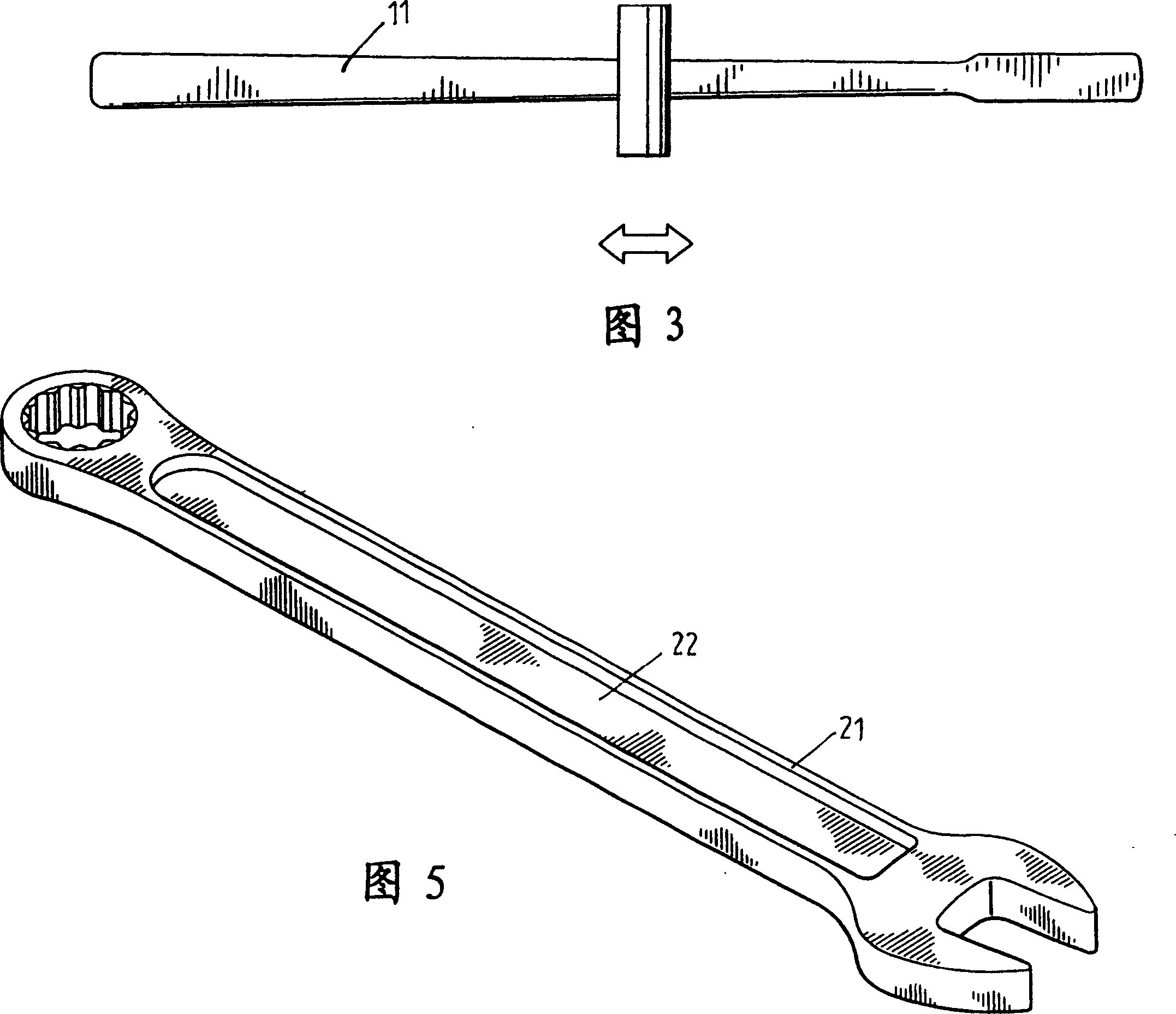

[0040] 1. Forging for the first time: using hot forging to forge a rough blank wrench with an I-shaped grip part 21. At this time, the rough blank wrench has a relatively rough shape of the I-shaped grip part;

[0041] 2. The second forging: the rough blank wrench that was hot forged for the first time is forged for the second time, and the fine blank wrench 22 is forged using a warm forging method that is lower in temperature than the first forging. The second warm forging method is used for forging, so the forged fine blank wrench 22 can have better dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com