Liquid discharging head, liquid-discharging device and producing method for liquid-discharging head

A liquid discharge head, liquid technology, applied in the manufacture of such a liquid discharge head, a liquid discharge and recording device, a liquid discharge device, and the field of the manufacture of such a discharge head, can solve problems such as pinholes and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

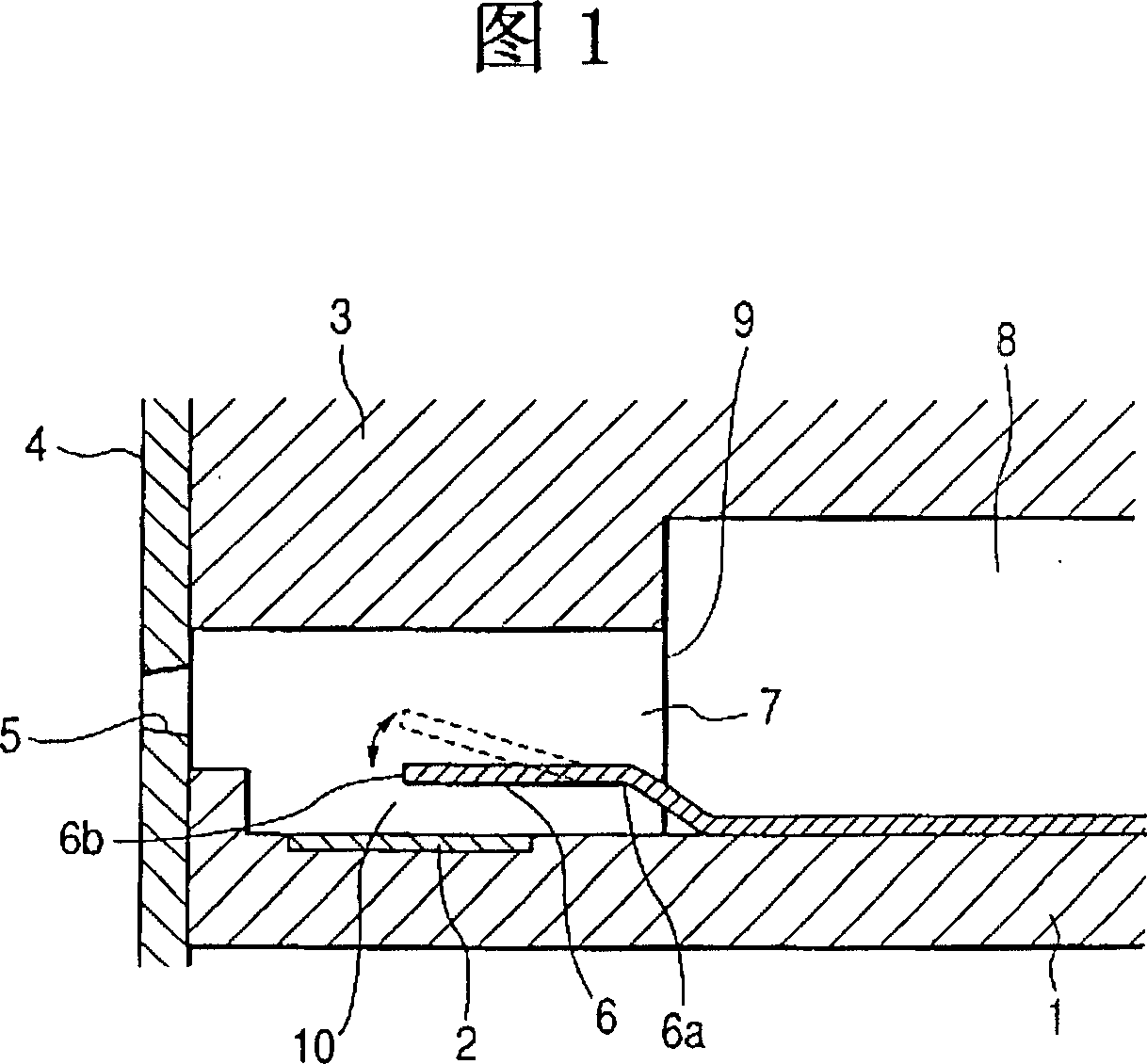

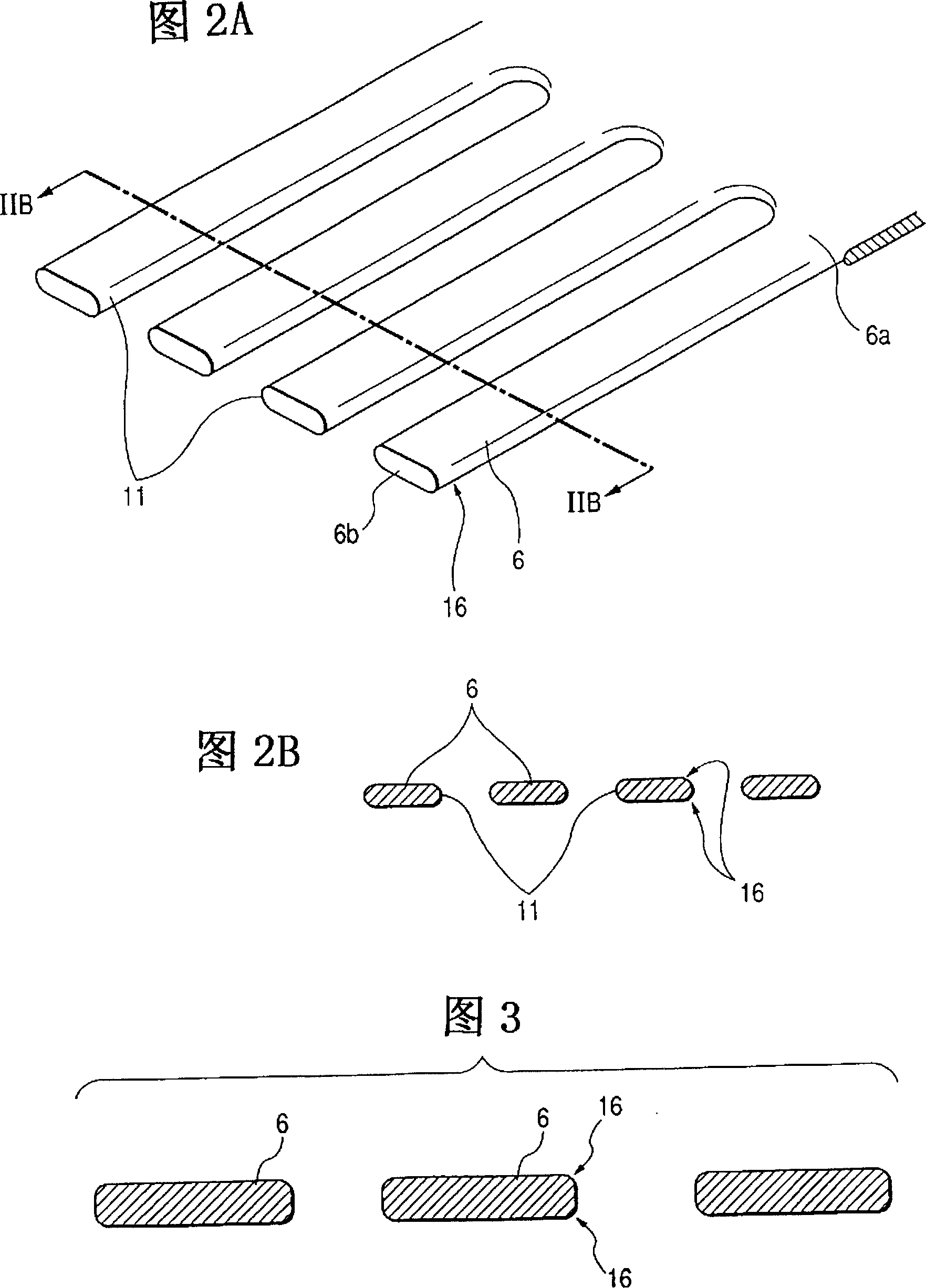

[0065] FIG. 1 is a sectional view along a liquid flow direction for explaining the basic structure of a liquid discharge head according to a first embodiment of the present invention. The liquid discharge head of the present invention has as shown in Figure 1: a device substrate 1, on which a plurality of (only one is shown in Figure 1) heating elements 2 installed in parallel as discharge energy generating means, which generate thermal energy Make the liquid generate bubbles and apply heat energy to the liquid; the top plate 3 attached to the top of the device substrate 1 ;

[0066] The device substrate 1 is an element with heat insulation and heat storage, and a silicon dioxide film or a silicon nitride film is formed on a substrate made of silicon and other materials, and a resistance layer and a heating element 2 are formed on it. The wires form a pattern. The heating element 2 is heated by applying a voltage from a wire to the resistance layer and supplying a current to ...

no. 2 example

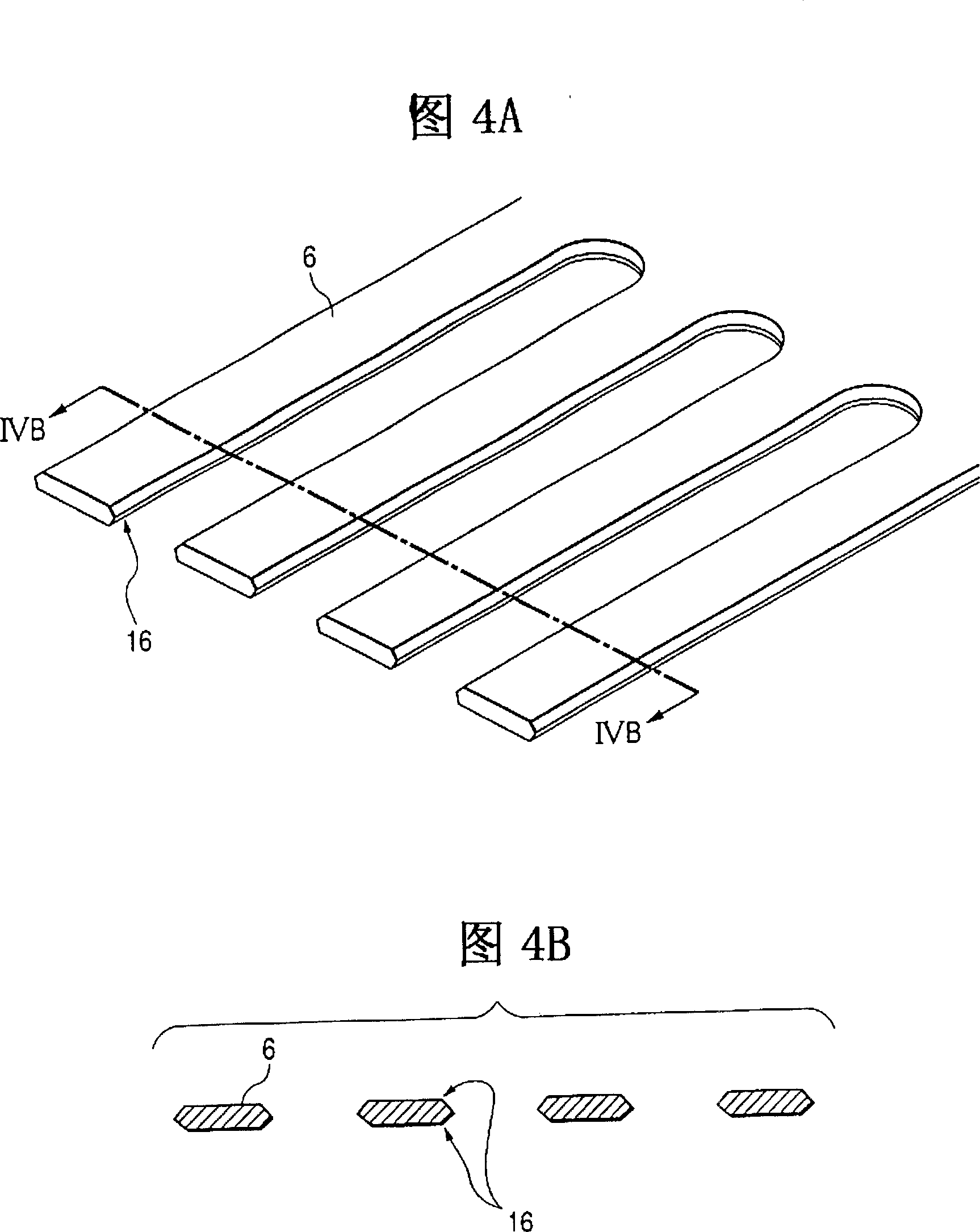

[0103] 9A, 9B are cross-sectional views for explaining the structure of a liquid discharge head manufactured by a method of manufacturing a liquid discharge head according to a second embodiment of the present invention. The liquid discharge head according to this embodiment is mainly different from the liquid discharge head of the first embodiment in that the width of the electrode layer on the device substrate is smaller than that of the movable member. Differences from the first embodiment are mainly described below. In Figs. 9A and 9B, the same reference numerals are used for the same parts as those of the first embodiment.

[0104] In the liquid discharge head according to the present embodiment, as shown in FIGS. 9A and 9B , the width W6 on the movable member 6 in the direction perpendicular to the liquid flow direction of the liquid flow path 7 and parallel to the surface of the device substrate 1 greater than the width W5 in the direction perpendicular to the liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com