Impregnation pretreatment technology of raw material used in soda process pulp making

A caustic soda pulping and pretreatment technology, applied in the direction of fine split raw material pretreatment, fiber raw material treatment, inorganic alkali pulping, etc., can solve the problems of high carbohydrate content, influence of pulping process, high viscosity of black liquor, etc. , to achieve the effect of easy beating, good drainage and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

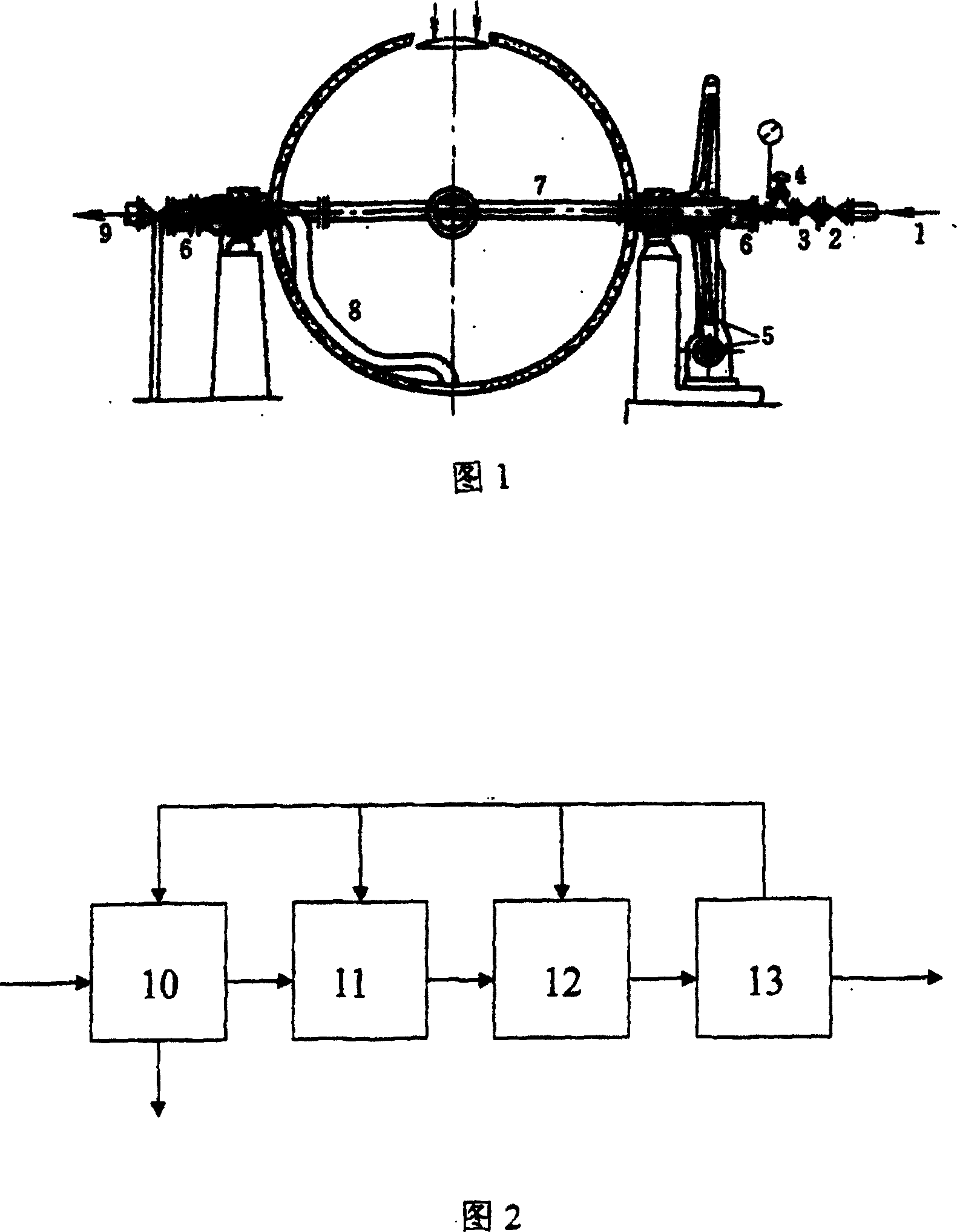

Method used

Image

Examples

Embodiment 1

[0045] In this example, for the dipping treatment process used in alkaline pulping, 25 cubic meters of steamed balls are used as the cooking vessel, and the length of the preliminarily treated wheat straw is 2-3 cm, and 4.8 tons of dry wheat straw is placed in the dipping screw machine and added Heated impregnating liquid, the impregnating liquid is composed of caustic soda and No. 2 black liquor. The concentration of adding alkali is the NaOH (sodium hydroxide) solution of the percentage of 14% absolute dry grass weight, the content of sodium hydroxide in the steeping liquid is 28 g / liter, the weight of the dry wheat straw amount (T) and the total liquid amount of the steeping liquid The ratio is 1:3.5. After adding the impregnating liquid wheat straw into the impregnating screw machine, rotate and impregnate under normal pressure for 0.25 hours, so that the impregnating liquid can fully contact with the raw materials, so that the raw materials can be impregnated evenly. Afte...

Embodiment 2

[0047] The equipment used in the present embodiment and process condition are basically the same as embodiment 1, only difference is that the concentration of adding alkali is 13% absolute dry grass weight percent, NaOH content 35 g / liter in the steeping liquid, absolute dry wheat straw amount (T) and The weight ratio of the total liquid volume of the soaking liquid is 1:3.9, and the impregnating liquid is rotated and soaked for 0.4 hours under normal pressure. The soaking liquid is heated to 95 degrees and mixed with the wheat straw, and kept for 30 minutes by rotating.

Embodiment 3

[0049] The equipment and process conditions used in this embodiment are basically the same as in Example 1, except that the concentration of alkali added is 15% by weight percentage of absolute dry grass, and the content of sodium hydroxide in the soaking liquid is 32 grams per liter. The weight ratio of the amount (T) to the total liquid volume of the soaking liquid is 1:4.2, and the dipping is rotated under normal pressure for 0.3 hours, and the soaking liquid is heated to 85 degrees and mixed with wheat straw, and rotated for 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com