Refrigerator chamber and its manufacture

A technology for cabinets and refrigerators, which is applied to household refrigeration devices, lighting and heating equipment, and household appliances. It can solve problems such as structural design is not simple enough, and achieve the effects of precise product size, cost reduction, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

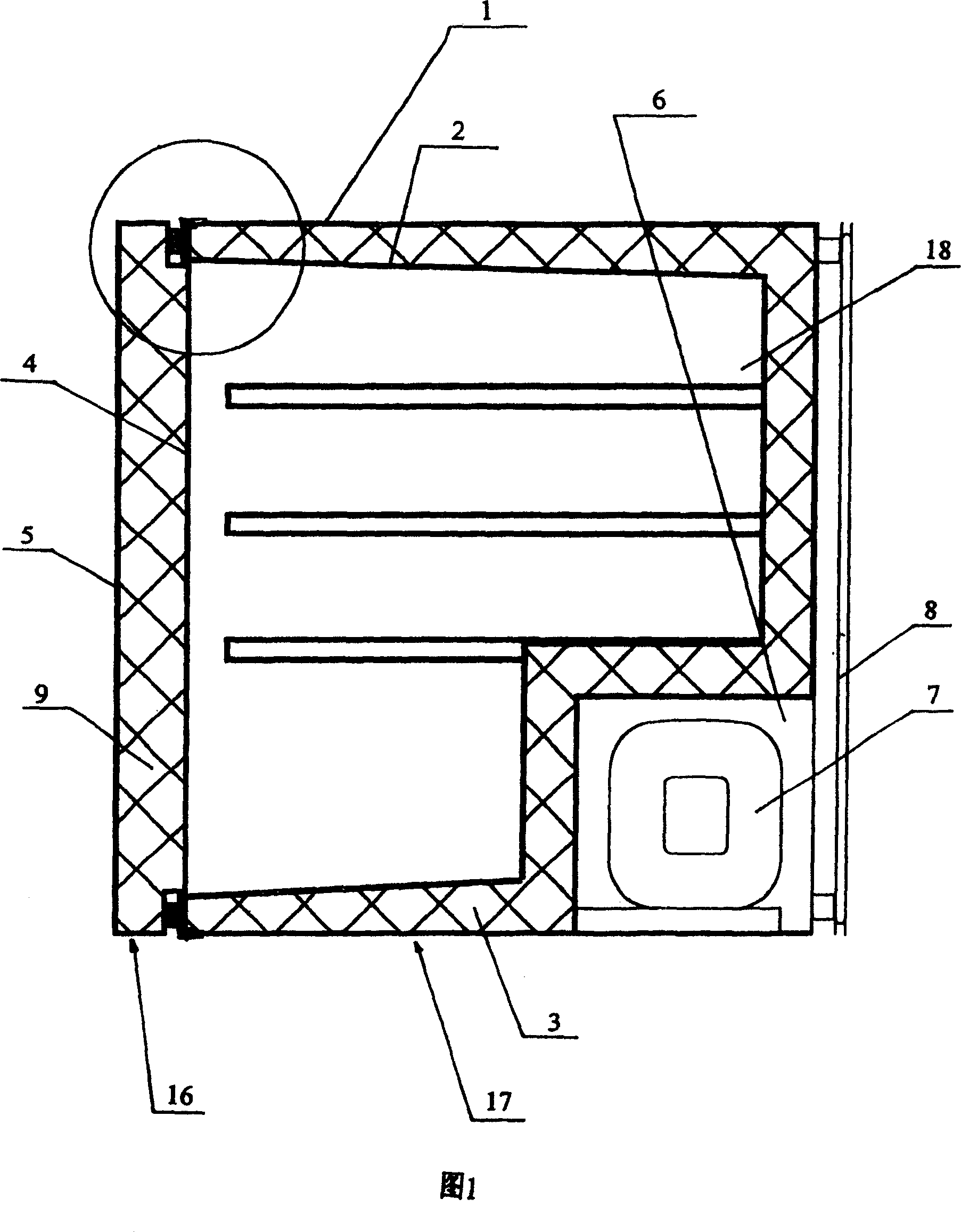

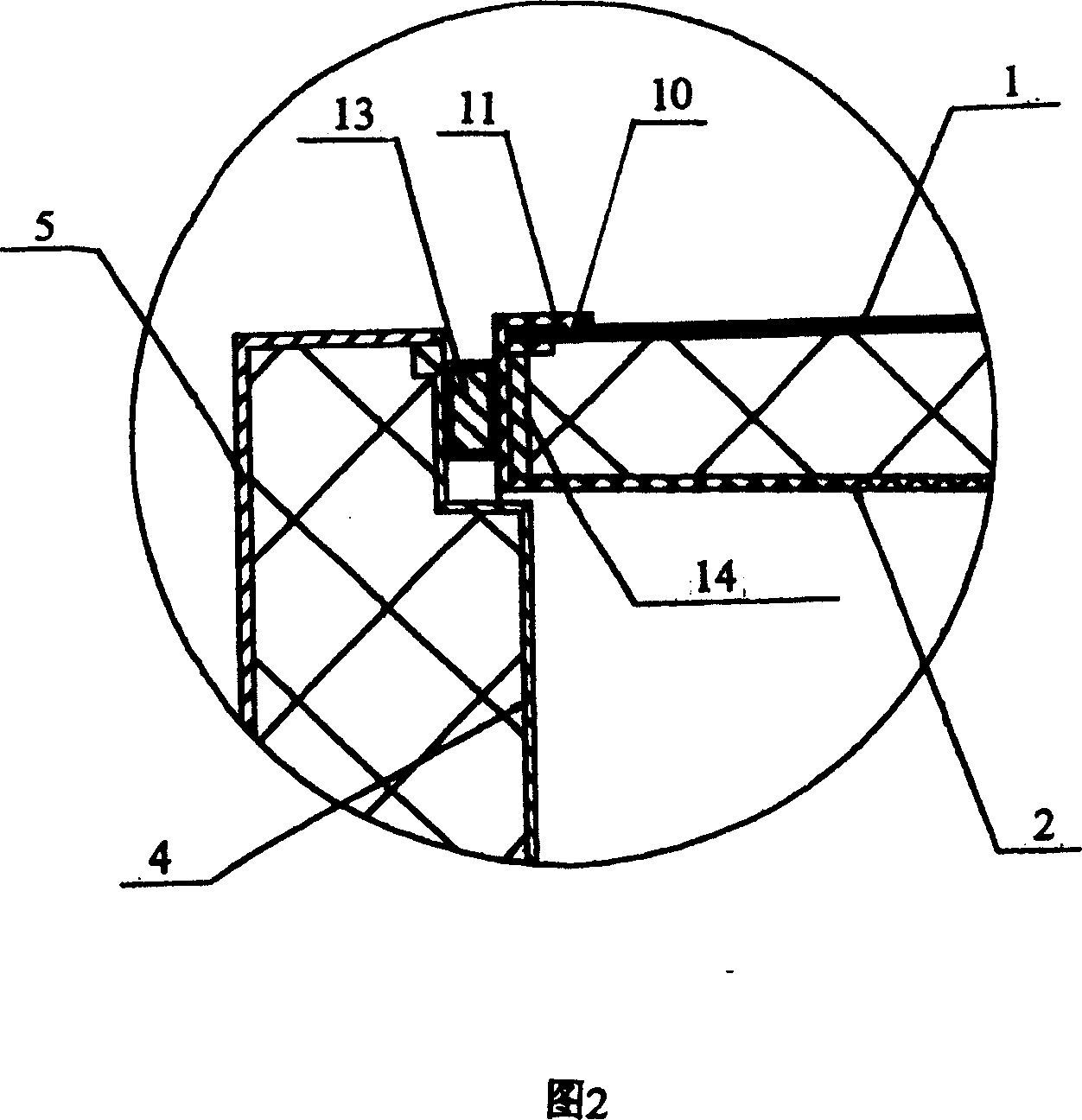

[0021] Embodiment 1, as shown in Figure 1-2, the refrigerator box includes a box body 17 and a door 16. The front side of the box body 17 is open, and its side is openable with the door 16 through a rotating shaft and a shaft sleeve structure. connection. It divides the housing that contains the overall insulation layer 3 in the refrigerator box 17 into two large plastic parts, one of which is the inner shell 2 that integrates the front of the box body 17 with the liner 18, and the other is the outer surface of the outer box. The casing 1 integrated with the compressor installation cavity 6 is also divided into two plastic parts, the front casing 5 and the rear casing 4, and the front casing 5 has a backward flange to cooperate with the rear casing 4. Plastic parts are processed by injection molding machines and injection molded in pre-designed molds. The shell 1 is formed with hasp holes 10 on the front opening, and each face of the shell 1 is two. Correspondingly, the inner...

Embodiment 2

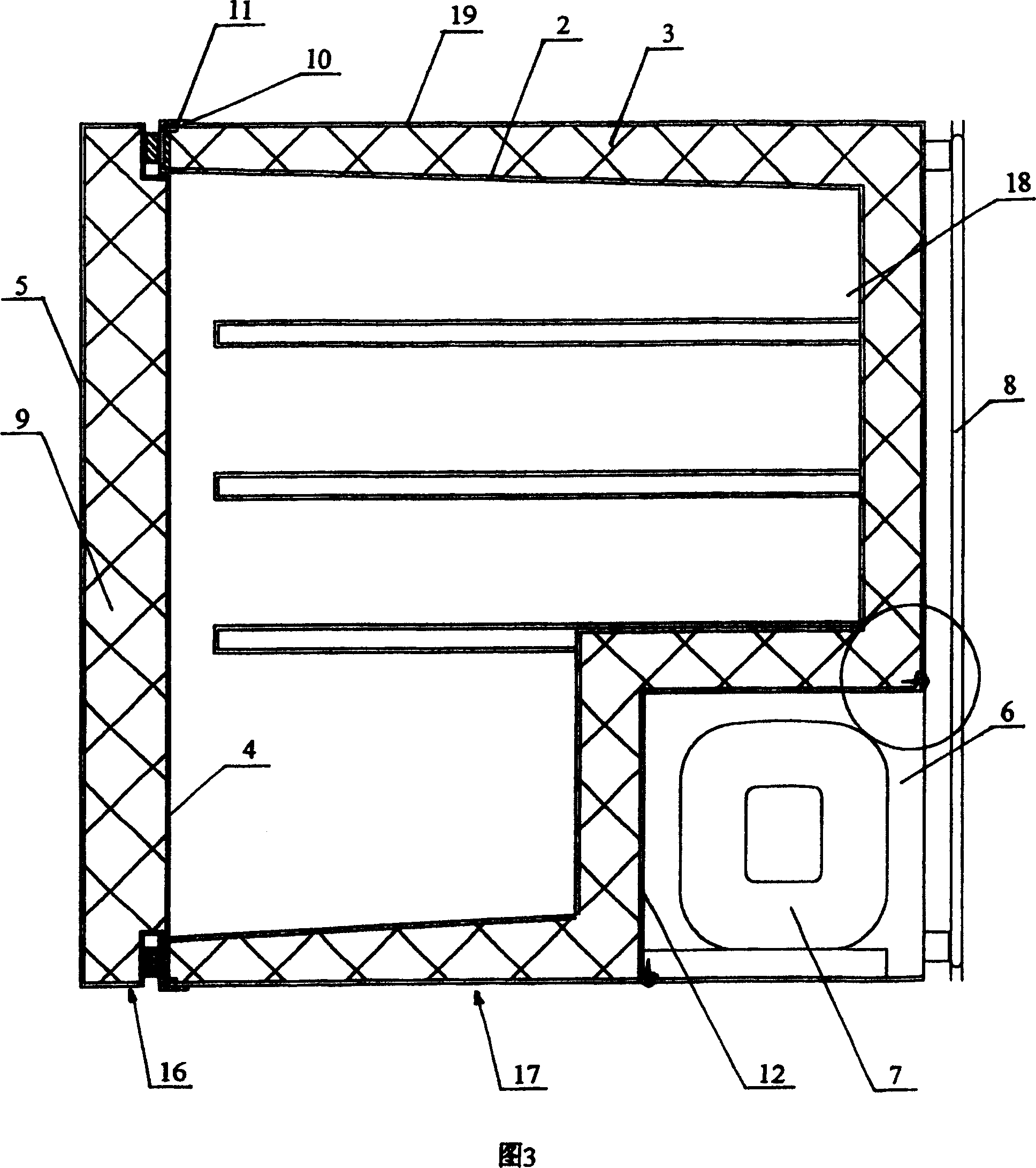

[0022]Embodiment 2, as shown in Figures 3-4, the refrigerator box includes a box body 17 and a door 16. The front side of the box body 17 is open, and its side is openable with the door 16 through a rotating shaft and a shaft sleeve structure. connection. It divides the housing containing the overall insulation layer 3 in the refrigerator box into three large plastic parts, one of which is the inner shell 2 integrated with the front of the box body 17 and the inner tank 18, and one is the upper surface and lower surface of the outer box. The upper part of the surface, both sides and the back constitutes an exposed rear cover shell 19 of an integrated structure, and the other part is a rear cover 12 matching the exposed rear cover shell, and the rear cover 12 is bent and concave to form a compressor installation cavity 6 , the door 16 is also divided into two plastic parts, the front shell 5 and the rear shell 4. The front shell 5 has a backward flange to cooperate with the rea...

Embodiment 3

[0023] Embodiment 3, as shown in Figures 5-6, the refrigerator box includes a box and a door, the front of the box is open, and its side is openably connected to the door through a rotating shaft and a shaft sleeve structure. It divides the housing containing the overall insulation layer 3 in the refrigerator box into two large plastic parts, one of which is the inner shell 20 integrated with the inner tank 18, the upper and lower sides of the box, the left and right sides, the front of the box, and the inner shell 18. The inner casing 20 matches the rear cover 21, the lower part of the rear cover 21 is bent and concave to form the compressor installation cavity 6, the door is divided into two plastic parts, the front casing 5 and the rear casing 4, and the front casing 5 has a backward folding Edges cooperate with the rear casing 4, and these plastic parts are processed by an injection molding machine, and are injection molded in a pre-designed mold. The inner shell 20 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com