Reverse gear device of motorcycle

A reverse gear, motorcycle technology, applied to vehicle parts, vehicle gearboxes, wheel transmissions, etc., can solve the problems of large power loss, etc., and achieve convenient and free meshing, small force loss, and stable and reliable power transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

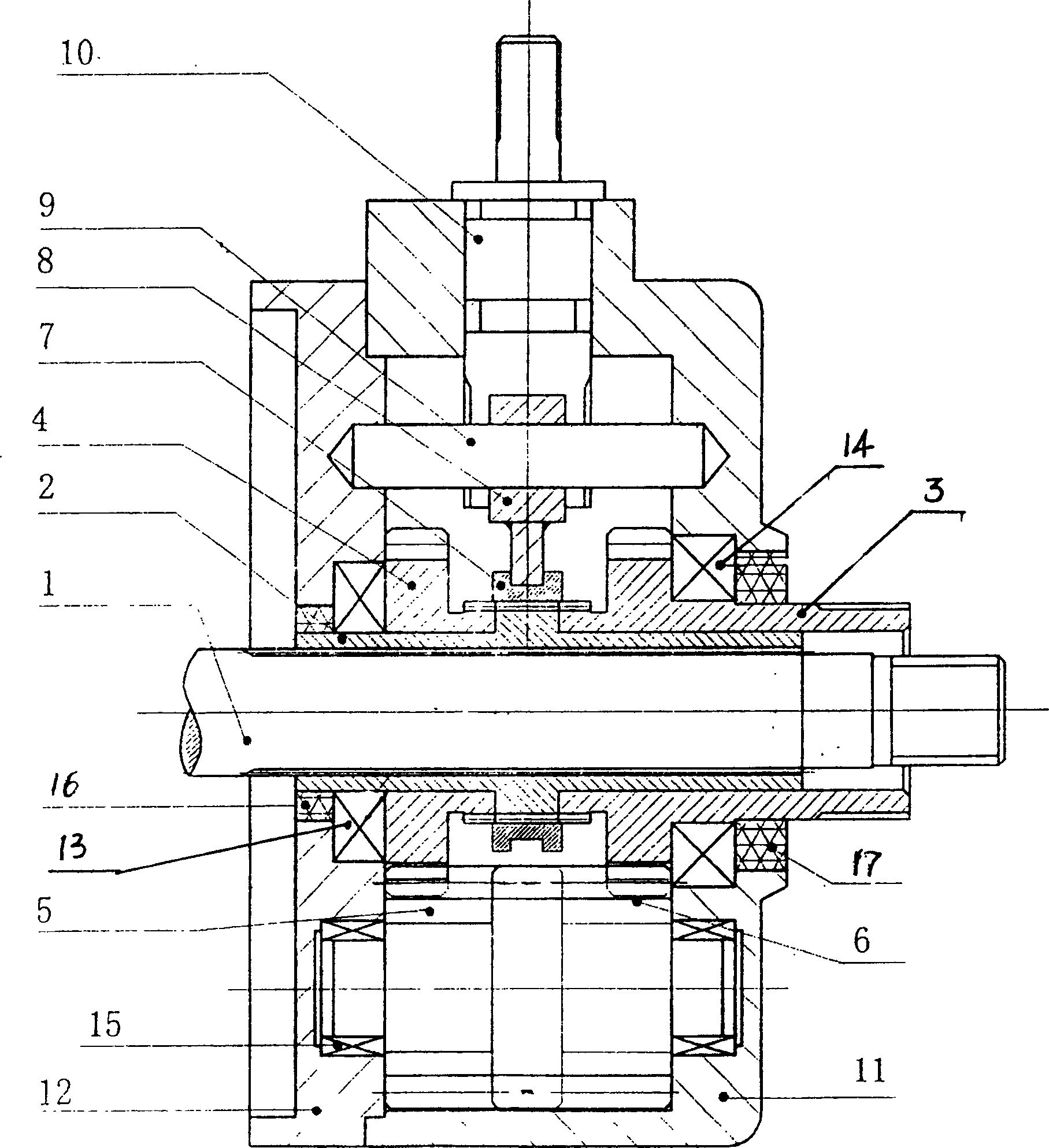

[0010] see figure 1 , The circumference of the spline sleeve 2 is provided with transmission teeth, the transmission teeth and the spline sleeve 2 are an integral part, and the internal teeth of the synchronous ring 7 mesh with the transmission teeth of the spline sleeve 2. The reverse gear 4 and the output gear sleeve 3 are respectively vacantly sleeved on the spline sleeve 2 on both sides of the transmission gear. Both the reverse gear 4 and the output gear sleeve 3 are integral duplex cylindrical teeth, and their combined teeth are adjacent to the drive teeth of the spline sleeve 2, and have the same number of teeth and the same modulus as the drive teeth. The coupling teeth of the reverse gear 4 and the output gear sleeve 3 and the internal teeth of the synchronizing ring 7 are all triangular teeth, so that the synchronizing ring 7 and the coupling teeth can be meshed conveniently and freely without interference. One end of the spline sleeve 2 is transitionally fitted wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com