Pigment-dispersed resist composition for color filters

A technology of color filters and resists, which is applied in the direction of optical filters, pigment pastes, photosensitive materials used in optical mechanical equipment, etc., can solve the problem that the pigment dispersion and fluidity of pigment dispersions are not fully improved, Particle increase, poor coating smoothness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

[0147] (The pigment dispersion of Example 7 is also the pigment-dispersed resist composition for a color filter of Example 7)

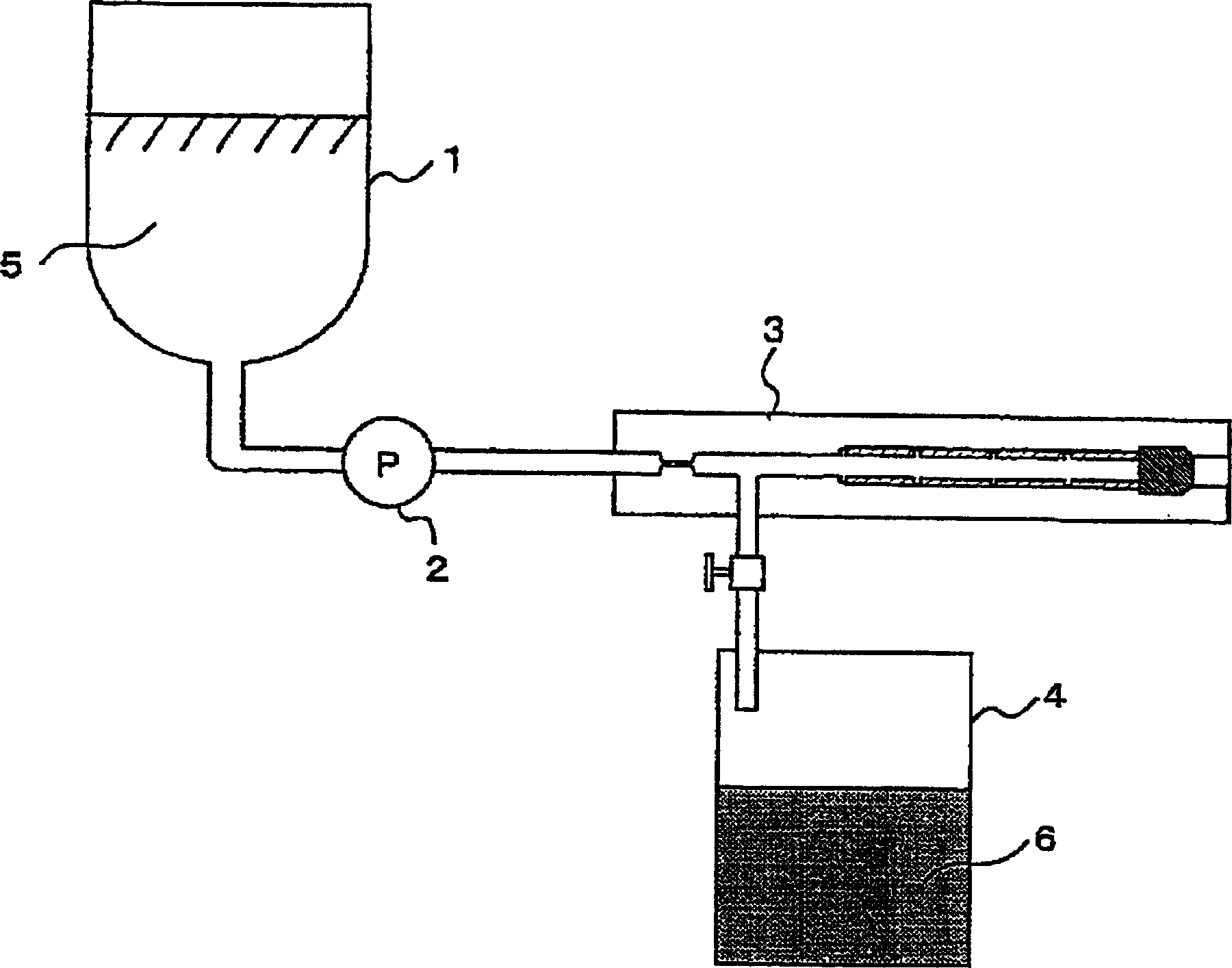

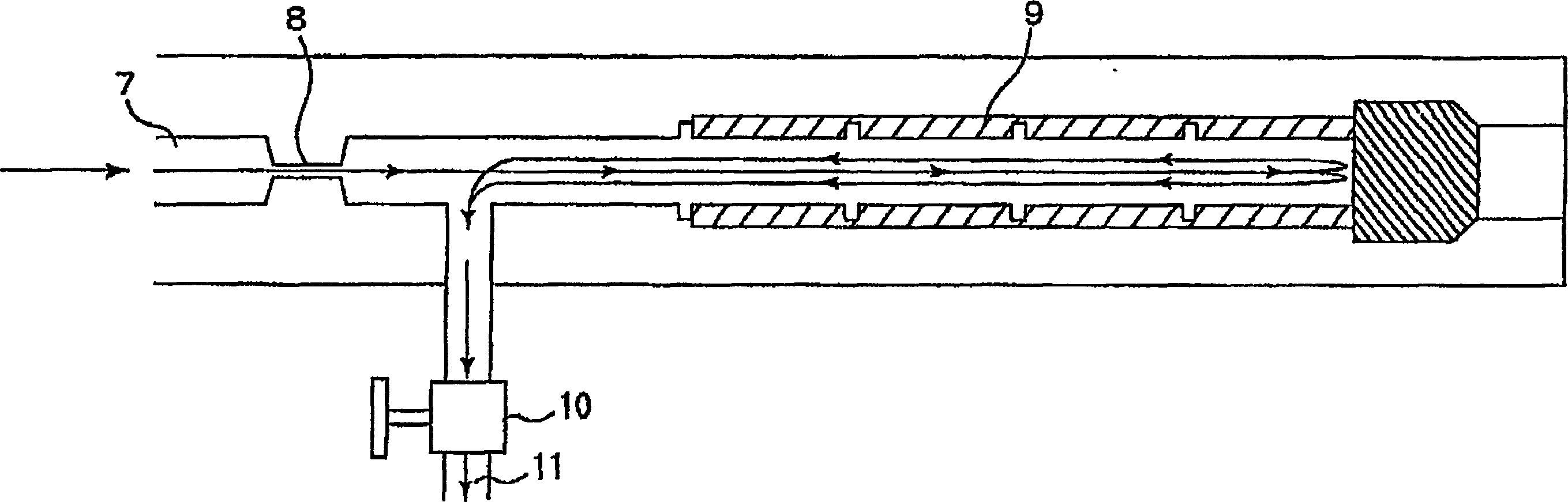

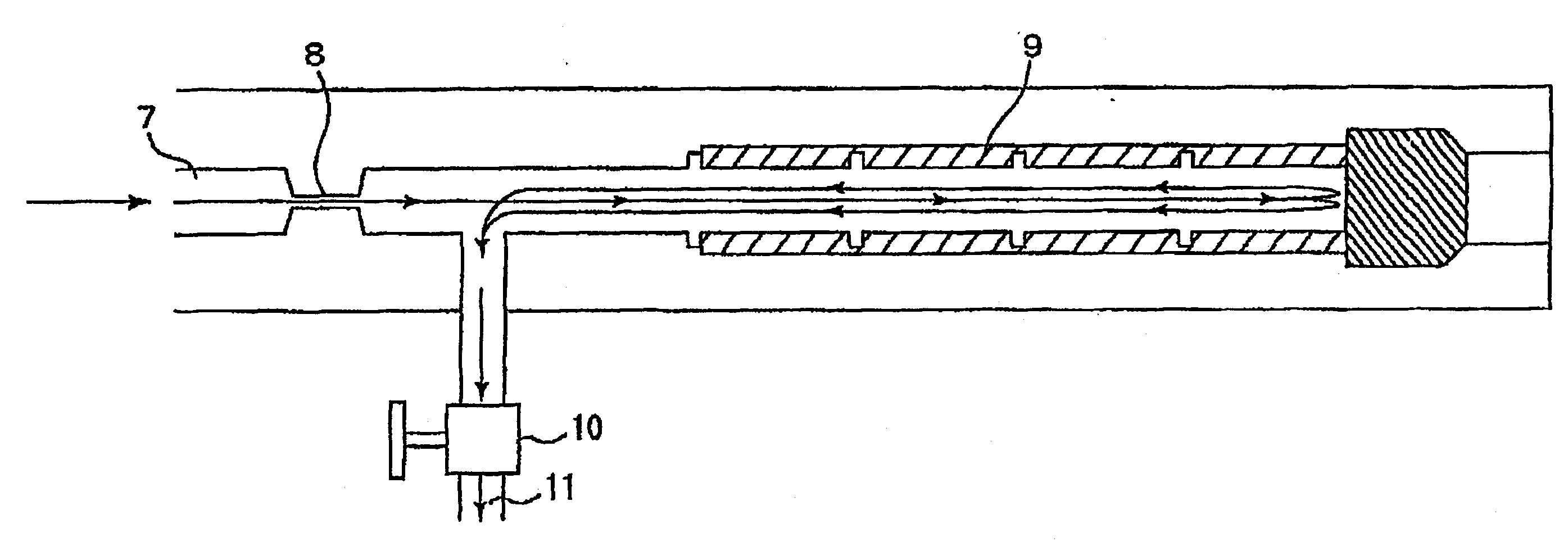

[0148] To 786 parts of PMAC, add 47 parts of pigment dispersant containing basic groups and 12 parts of acrylic resin, mix and prepare varnish, then add 155 parts of C.I. Pigment Red 254, and pre-disperse with high-speed mixer. Then, mix 60 parts of acrylic resins, 28 parts of dipentaerythritol hexaacrylate, 9 parts of photopolymerization initiators, 465 parts of PMAC in 438 parts of predispersions, stir, use figure 2 After the high-pressure emulsifier shown was dispersed according to the following conditions, the coarse particles were removed by filtration with a 3 μpp folded filter paper, and the pigment dispersion of Example 7 was obtained, and the pigment-dispersed resist for the color filter of Example 7 was obtained combination.

[0149]

[0150] Spread pressure: 2×10 5 kPa

[0151] Pre-dispersed dispersion flow rate: 600 m / s

[0152] Noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com