Railway clamp

A rail clip and rail technology, applied in the field of rail clips, can solve the problems of small differences in rail manufacturing tolerances, lateral displacement of rails, and the ability to reduce longitudinal sliding of rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

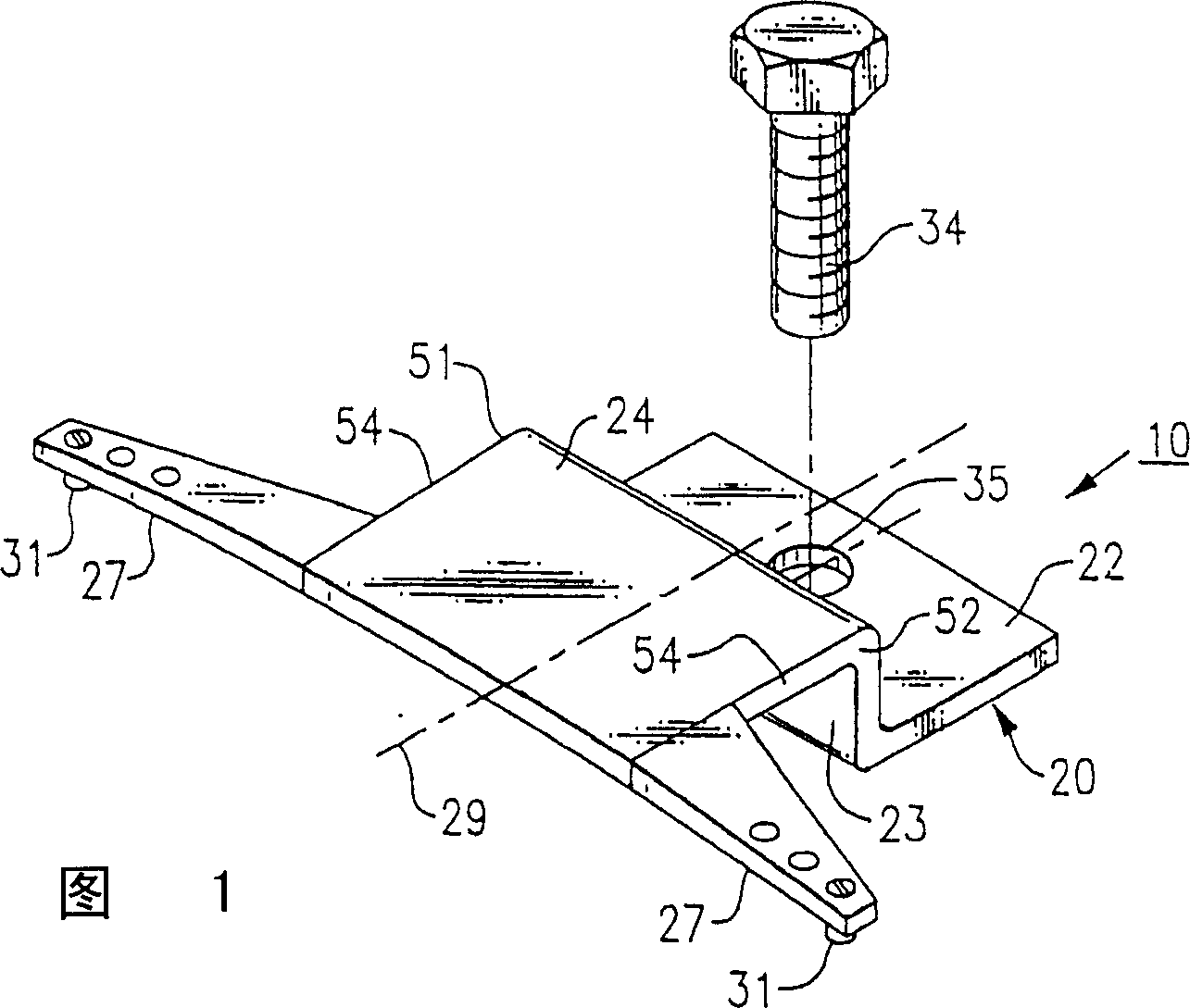

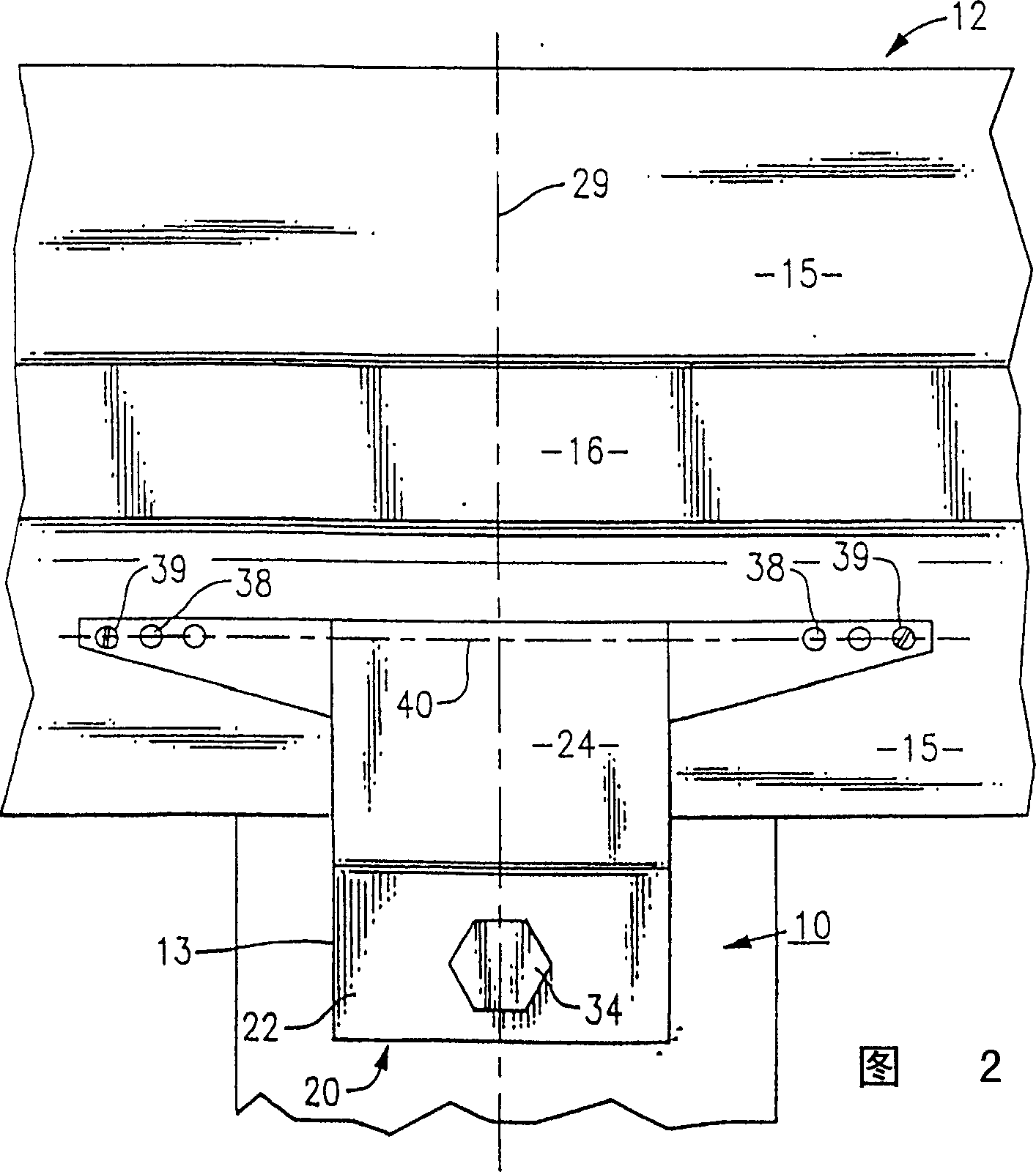

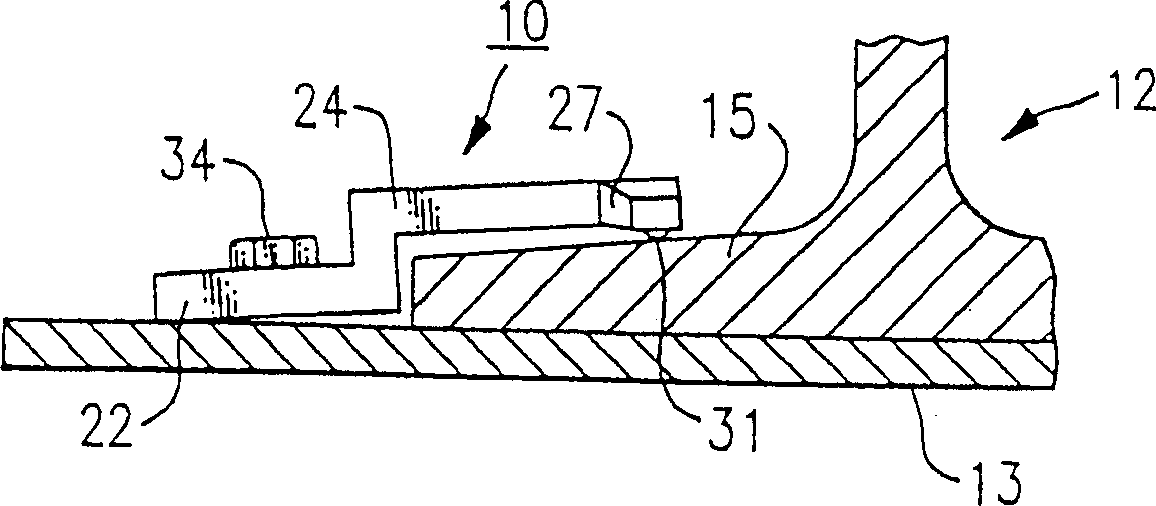

[0028] Referring initially to FIGS. 1 and 2 , there is shown a track clamp, generally designated 10 , which is ideally adapted to secure an elevator guide rail section 12 to a bottom support frame 13 . As previously mentioned, a typical guide rail currently in widespread use in many elevator systems has a T-shaped cross-sectional configuration and includes a bottom flange 15 and a web or riser 16 centered longitudinally along the flange. The elevator guide rail sections are assembled vertically aligned end-to-end. As is well known, elevator cabs and associated counterweight units are respectively mounted for free movement along a pair of spaced apart tracks on rollers or guide plates which straddle along the riser portions of each track.

[0029] Each track segment is connected to multiple support frames with a number of track clips. As will be explained in more detail below, each track clip initially exhibits a linear response that is sufficiently flexible to allow for longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com