Back-up tong binding clip chucking mechanism for open type power-driven clamp

A power tong, open-type technology, applied in the field of power tongs, can solve the problems of having to disassemble the tong head, increased surface damage of the pipe string, complicated structure, etc., achieving significant social and economic benefits, convenient use and maintenance, and improved operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

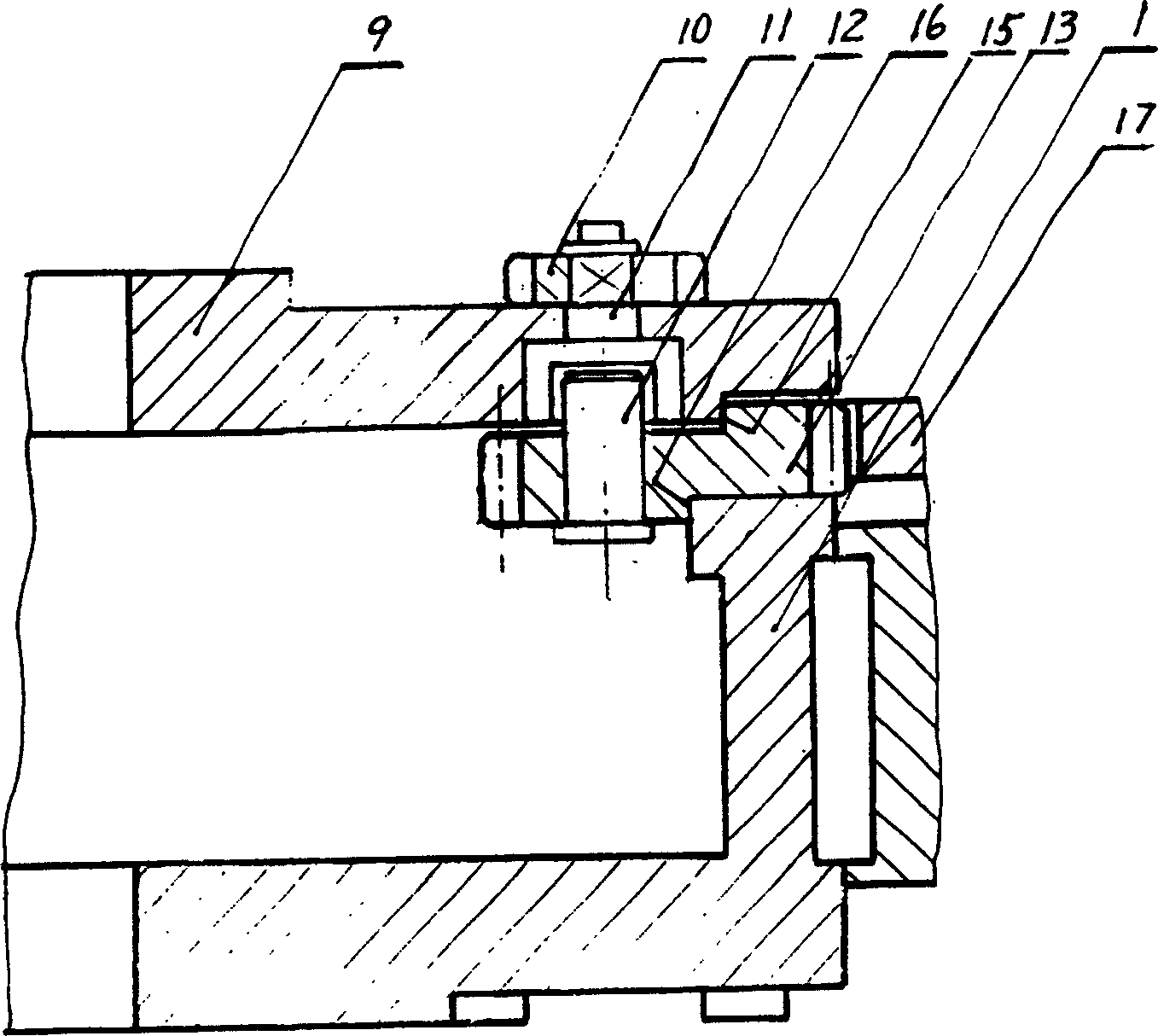

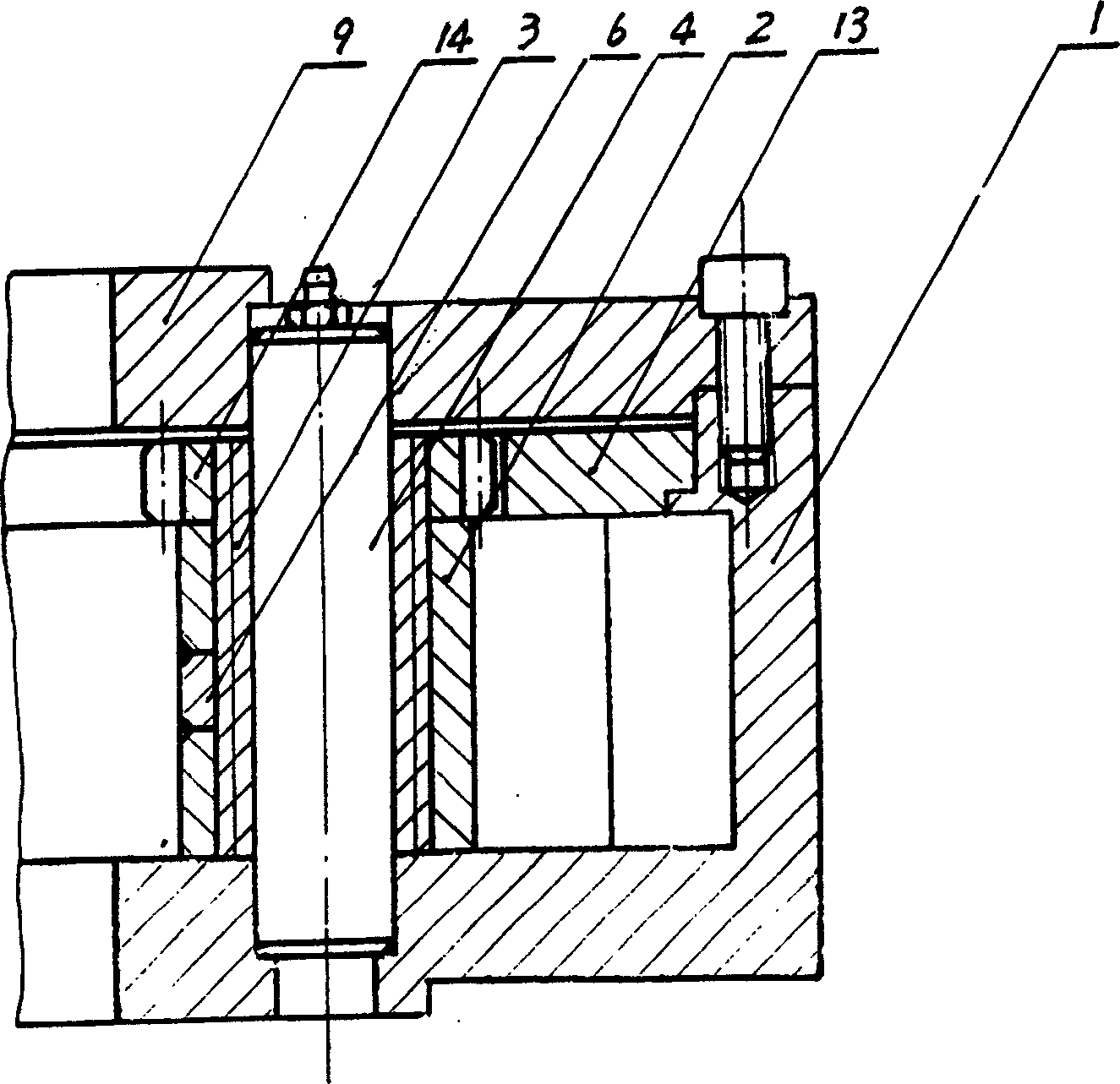

[0009] Such as figure 1 , 2 , shown in 3, a kind of opening type power pliers back pliers pincer head clamping mechanism, by back pliers main body 1, back pliers head cover plate 9, butterfly jaw plate 2, outer curved tooth plate 5, tooth plate stopper 6, Die plate screw 7, spline shaft sleeve 3, mandrel 4, planetary gear 14, gear ring 13, stop pin 12, knob shaft 11, knob gear 10, handle gear 8, back tong body 1 and back tong head cover plate 9 is connected and fastened together by screws, the tooth plate stopper 6 is welded on the butterfly jaw plate 2, the outer curved tooth plate 5 is limited by the tooth plate stopper 6 and fixed on the butterfly jaw plate 2 by the tooth plate screw 7 , remove the tooth plate screw 7, you can replace the outer curved tooth plate 5. The cusp contour curve of the outer curved tooth plate 5 is obtained by a special calculation method. The center line of curvature deviates from the center of the mandrel 4. When the tooth cusp of the outer cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com