Unit type intelligent gas pulse ash blower and its control method

A soot blowing device and unit type technology, applied in the field of automatic unit type intelligent gas pulse soot blowing device, can solve problems such as major accidents, failure to isolate faults in an automatic way, reliability, stability, and continuous failure-free operation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

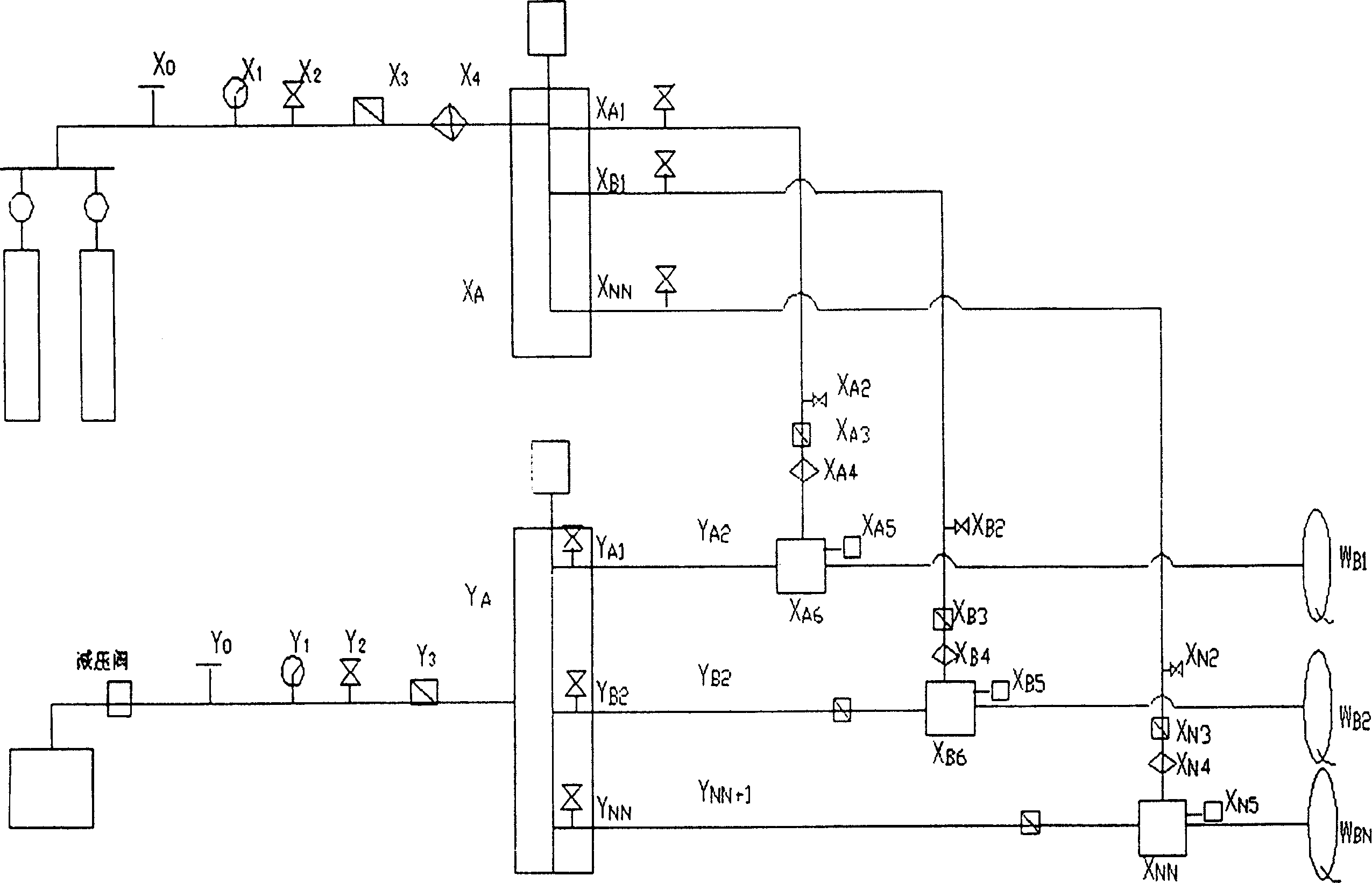

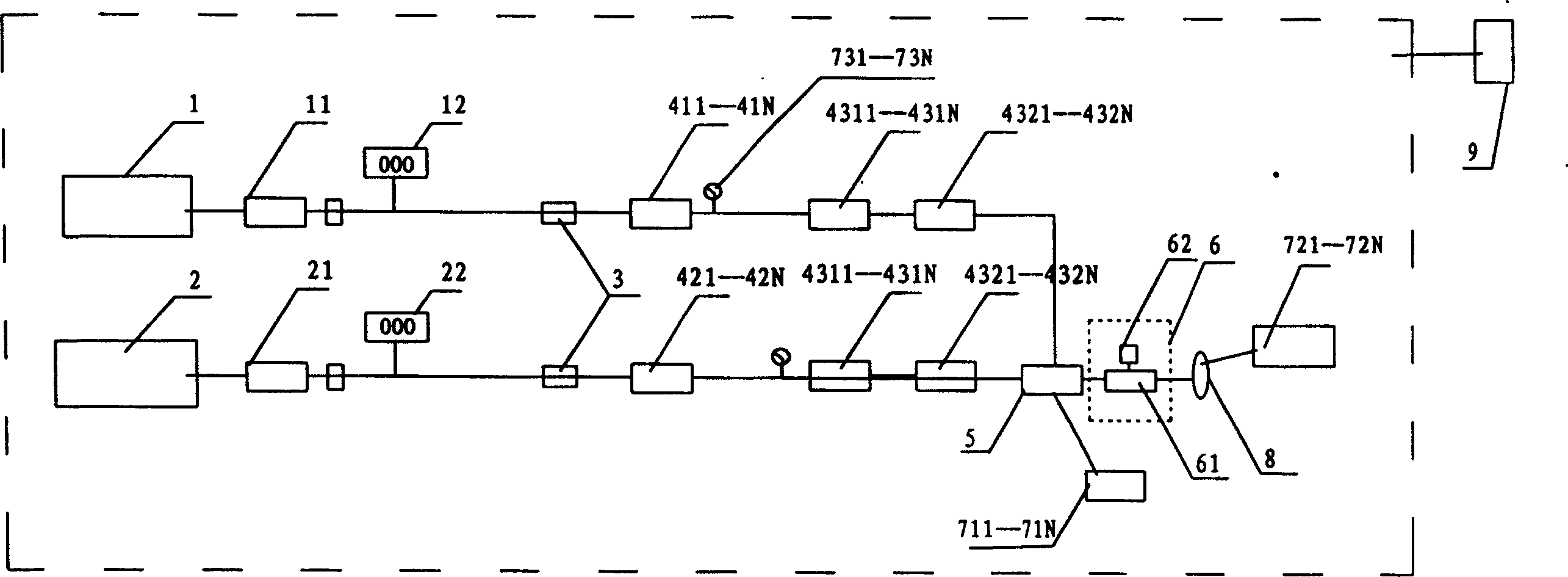

[0134] One, such as image 3 with Figure 4 Shown: The configuration components of the unit type intelligent gas pulse sootblower provided by the present invention are mainly composed of:

[0135] Combustible gas main gas source device 1, generally combustible gas (C 2 H 2 ), hydrogen (H 2 ), methane, natural gas, petrochemical by-product dry gas, etc., providing combustible gas, using acetylene (C 2 H 2 ) As an example, the pressure (0.09-0.15Mpa) and the air main air source device 2 provide air, which is opened and closed at the same time as the acetylene main air source device 1 (0.3-0.8Mpa). These two devices supply gas to the entire device, and at the same time install an acetylene main gas source control valve (ie, acetylene circuit main valve) 11 on the outlet pipe of the acetylene main gas source device. The main valve) 11 is a commercially available solenoid valve, which is closed when a certain program of the whole device ends or the main circuit fails; install an air ma...

specific Embodiment approach 2

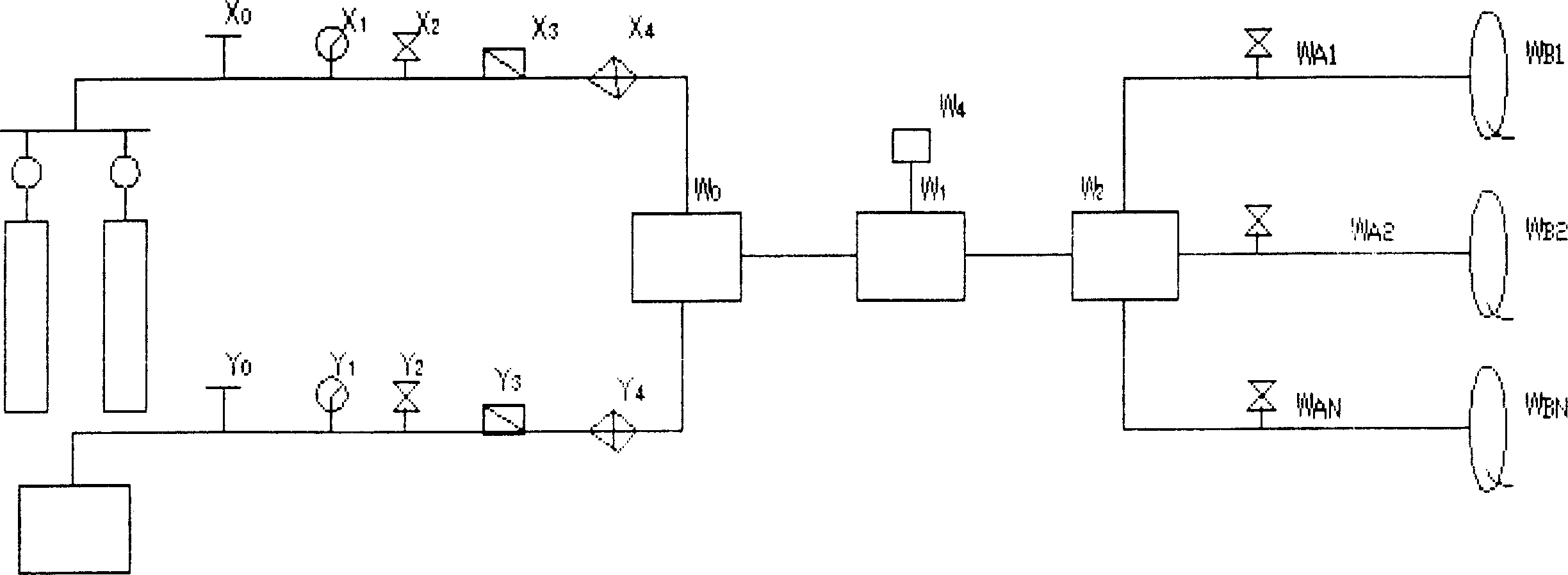

[0180] The control method of the parallel operation mode in the above embodiment can be used as figure 2 The described control method realizes the control of the soot blowing device of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com