Magnetic-conductive member end-part defect detection device

A defect detection and component technology, applied in the direction of material magnetic variables, etc., can solve the problems of difficult automatic detection, easy diffusion of magnetic field, complex mechanism and other problems, and achieve the effect of strong anti-interference ability, low labor intensity and flexible scanning mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

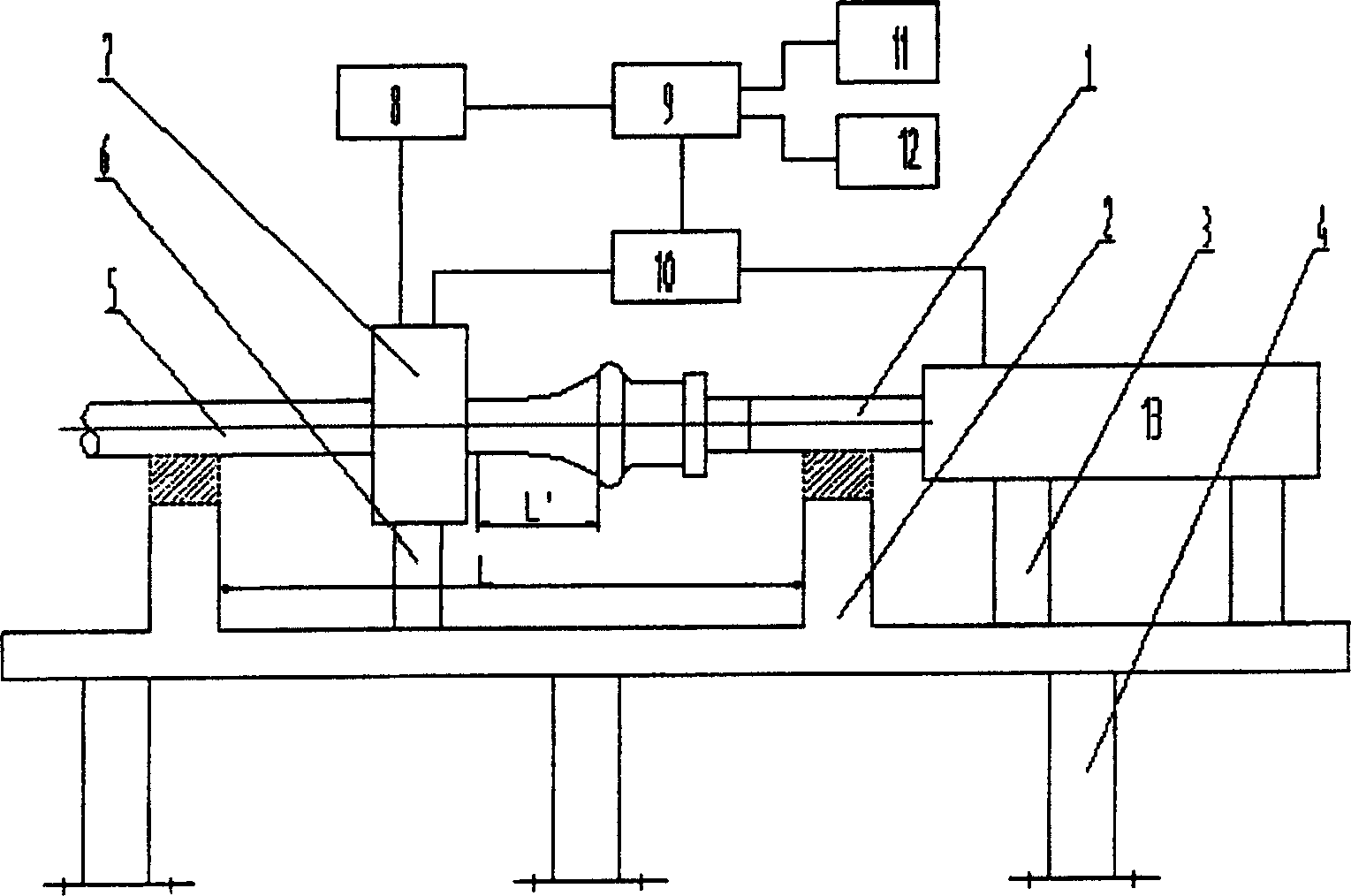

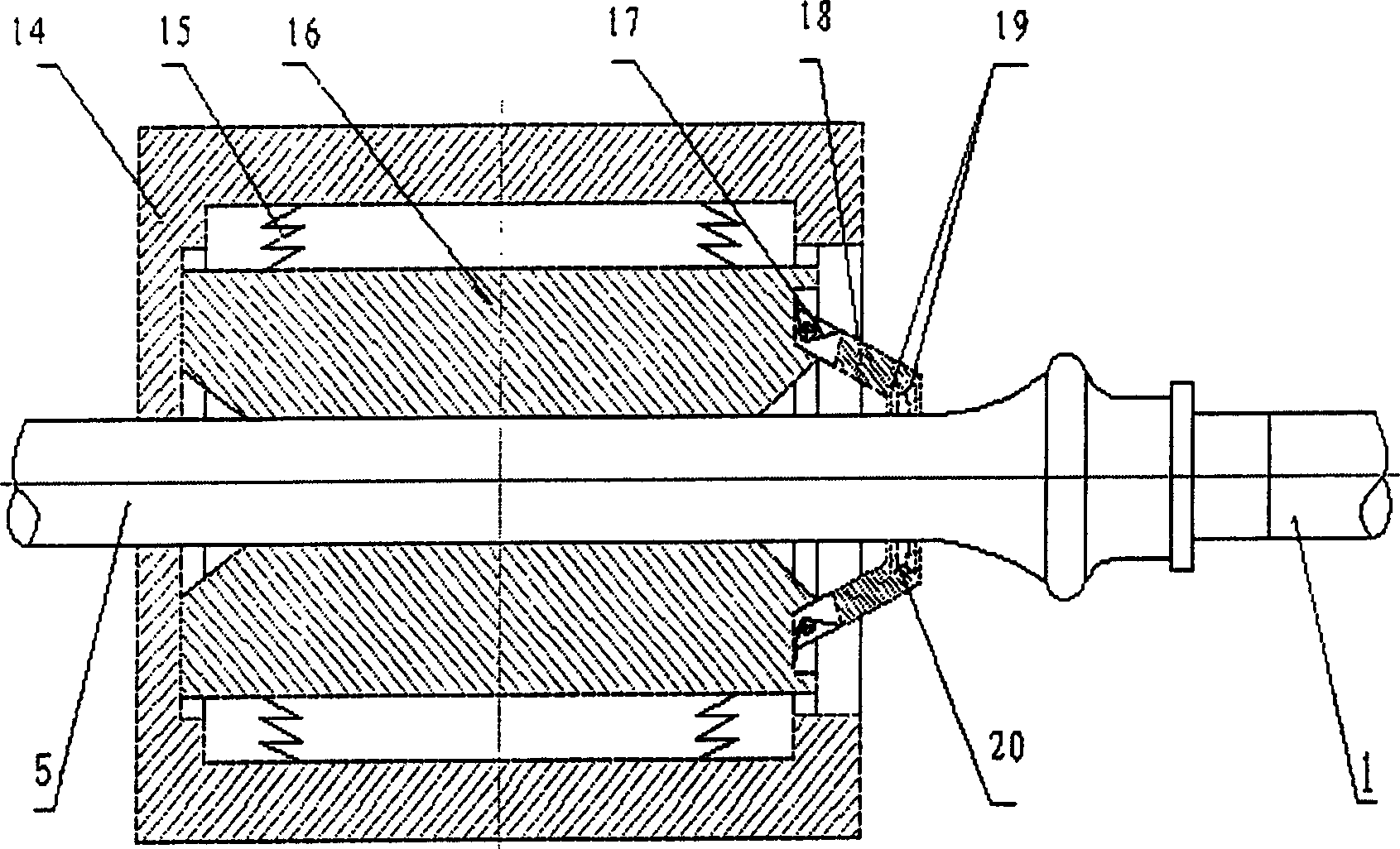

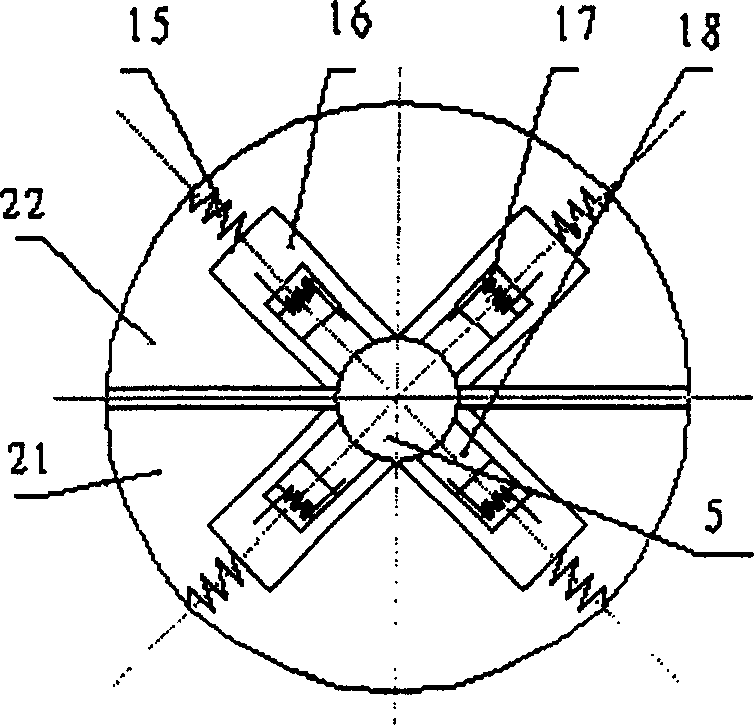

[0022] Such as figure 1 As shown, the whole device is mainly composed of auxiliary guide rod (1), magnetizer (2), detection probe (7), signal acquisition and preprocessor (8), signal processor (9), controller (10), scanning Drive mechanism (13) and display (11) printer (12) and necessary support (3), (4), (6) form. figure 1 (3) is used to support the scanning drive mechanism (13), (4) is used to support the whole system, and the whole device is fastened on the ground with expansion bolts, and (6) is used to support the detection probe (7). The magnetizer (2) is composed of an excitation source and an armature. The permanent magnet steel is used as the excitation source, and the beam in the device is used as a magnetically conductive armature to form a magnetic field when in contact with the guide rod (1) and the component under test (5). way to magnetize them. Depending on the cross-sectional area of the measured component (5), 2 to 50 pairs of magnetic steels can be selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com