Discharge lamp with helical discharge tube

A discharge tube, helical technology, applied in the field of low-pressure discharge lamps, to achieve the effects of avoiding bad connections, enhancing mechanical stability, and improving brightness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

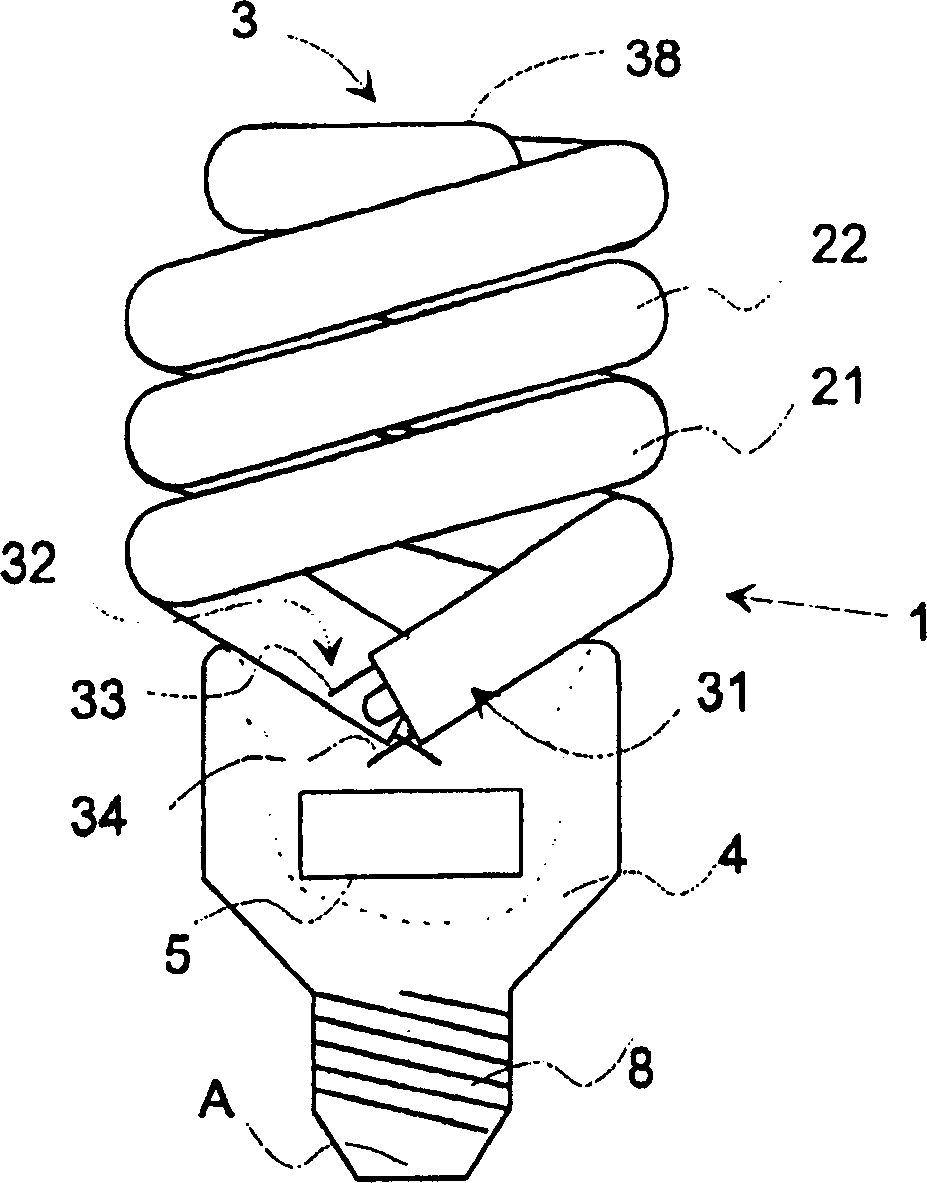

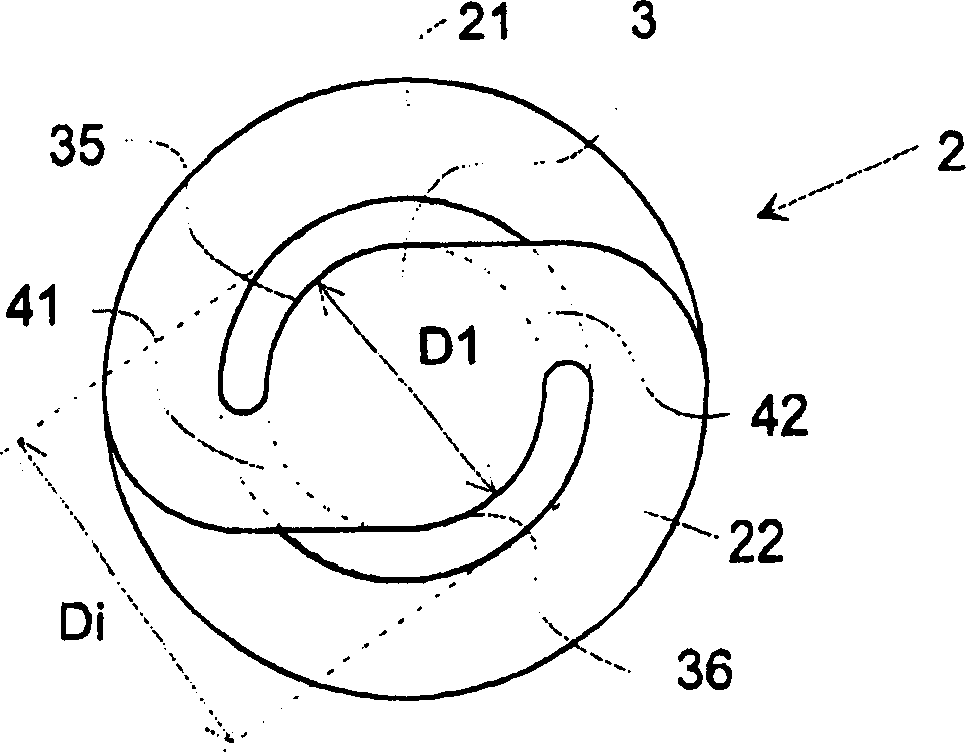

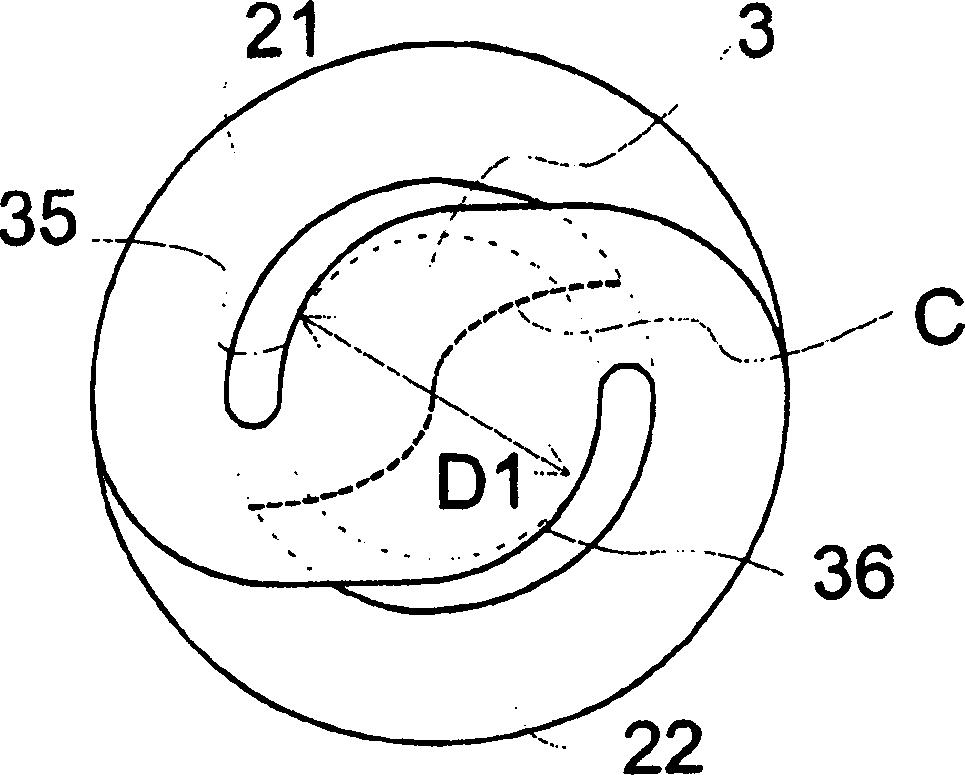

[0015] now refer to figure 1 and 2 , a low-pressure arc discharge lamp 1 is shown here. The discharge vessel 2 of the discharge lamp 1 has sealed ends 31 , 32 . figure 1 The discharge lamp 1 in has two helical discharge vessel parts 21 and 22 which are connected to each other by a low temperature chamber part 3 at the upper ends of the discharge vessel parts 21 and 22 .

[0016] The discharge tube 2 is mechanically supported by the lamp holder 4 . The lamp holder 4 surrounds the sealed ends 31 , 32 of the discharge vessel 2 . More precisely, the sealed ends 31 , 32 of the discharge tube parts 21 , 22 are inside the lamp holder 4 , while the main parts of the discharge tube parts 21 , 22 are outside the lamp holder 4 . The discharge lamp 1 is of the type that emits light from a layer of phosphor deposited on the inner surface of the discharge vessel 2, which phosphor is excited by the discharge arc. Electrons for the arc are emitted from a heated filament (not shown). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com