Method for preparing high activity alfalfa food fiber

A dietary fiber and high-activity technology, which is applied in food preparation, food science, application, etc., can solve the problems of the development and production of high-activity alfalfa fiber, so as to improve the technological content and economic added value, expand new application fields, The effect of shortening the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

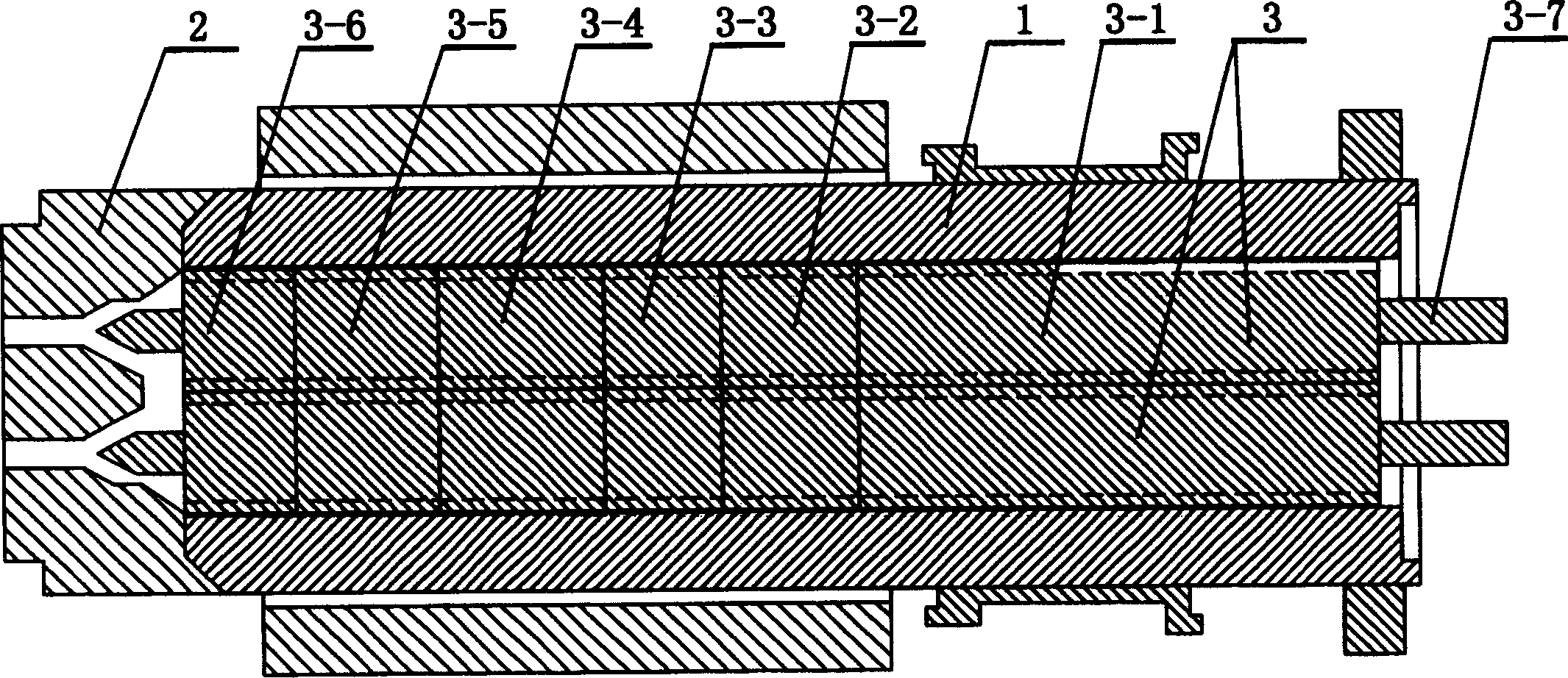

Image

Examples

Embodiment Construction

[0026] 1. Preparation of alfalfa leaf residue

[0027] Select fresh and tender alfalfa stems and leaves, roughly crush them with a pulverizer to a particle size of 2-4 mm, add appropriate amount of water to beat three times, and then press through a screw press unit to separate the alfalfa leaf residue, which contains more than 75% of the total dietary fiber content. The basic component is fiber, including cellulose, hemicellulose and lignin.

[0028] 2. Pretreatment of alfalfa leaf residue

[0029] Soaking and rinsing: After the fresh stems and leaves are separated by pressing, the leaf dregs must first be soaked and rinsed to soften the fibers, and at the same time wash off the residual soluble impurities on the surface of the leaf dregs, and control the concentration of the leaf dregs within the range of 12-20%. Careful control, water temperature 36 ~ 40 ℃, time 1.5 ~ 2h is appropriate.

[0030] Removal of grassy smell: the method of cooking with alkali is used to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com